It was a cold Tuesday morning in my garage. I had my coffee in one hand and my Bostitch brad nailer in the other. I was finishing a small shelf for my kid. I pulled the trigger, but nothing happened. No nail came out, and my heart sank.

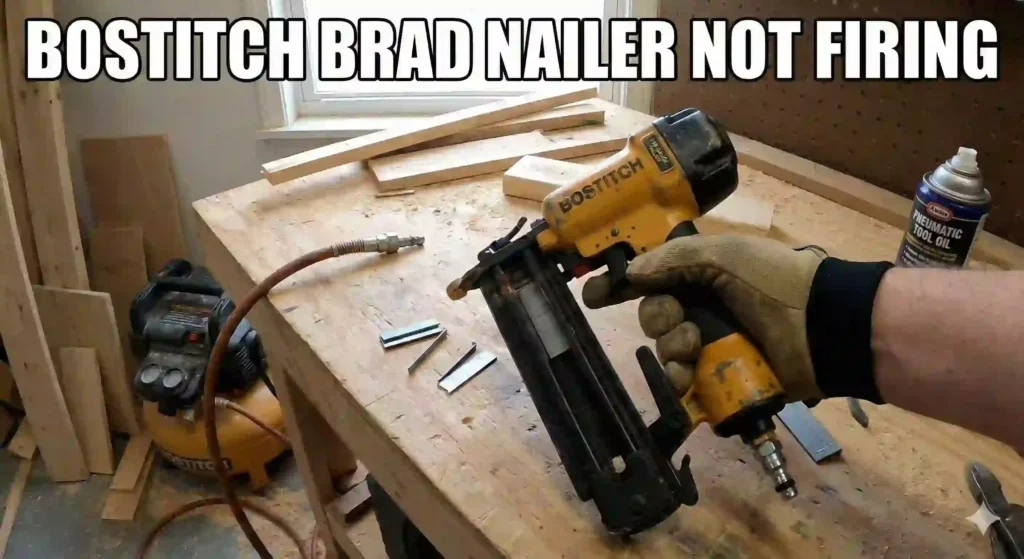

When your Bostitch brad nailer is not firing, it feels like the whole project is stuck. I have spent years using these tools in my shop. I know the smell of the oil and the sound of the air. Most of the time, the fix is very simple and takes just a few minutes.

Why Your Bostitch Brad Nailer Is Not Firing

I used to think a quiet gun meant it was dead. Now I know it just needs a little bit of love. These tools are tough, but they rely on air and seals to work. If one part fails, the whole gun stops.

Quick Fix Guide for Your Shop

| Symptom | What I Check | My Quick Fix |

| A dull thud sound | Air Pressure | Set compressor to 90 PSI |

| Air hissing noise | Dry O-rings | Add 3 drops of tool oil |

| Trigger feels limp | Safety Nose | Clean out the wood dust |

| Blade moves, no nail | Jammed strip | Open the front nose latch |

Checking Your Air Supply

The first thing I always check is the air hose. I once spent ten minutes getting mad at my gun, only to find the hose was pinched. Most Bostitch tools need at least 80 PSI to fire a nail into hard wood.

Check your compressor gauge to see if it is high enough. If the air is too low, the driver blade will not move. I find that 90 to 100 PSI is the sweet spot for most of my trim work. It gives the gun enough punch to sink the nail every single time.

Dealing with the Dreaded Nail Jam

If your gun makes a sound but no nail appears, you have a jam. This happened to me last week when I used a cheap brand of nails. A tiny bit of metal got stuck in the track and stopped everything.

How I Clear a Stuck Nail

First, I always unplug the air hose for safety. Then, I pull back the magazine to see the nails. I love that Bostitch has a tool-free latch on the front of the gun. I just flip the silver lever and the nose pops open wide.

I keep a small pair of pliers on my bench for this task. I grab the bent nail and pull it straight out. Do not force it or you might scratch the metal. Once the path is clear, I snap the latch shut and get back to work.

The Magic of Tool Oil

I will be honest with you. For a long time, I forgot to oil my tools. Then, my nailer started to sound like it was gasping for air. I realized the rubber seals inside had dried out and were starting to leak.

Air tools need oil to keep the O-rings slick and soft. I now keep a small bottle of oil right next to my box of nails. I put two drops into the air plug before I start any project. It makes the gun fire much faster and stops air from leaking out.

Cleaning the Safety Nose

The tip of the gun is a safety trigger that you must press down. In a dusty shop, this part can get stuck with sawdust or glue. If it does not move, the gun will think you are not ready to fire.

I use a can of compressed air to blow out the gunk from the tip. I also check the spring to make sure it is still bouncy. A clean safety nose makes the tool feel brand new. It is a simple step that saves me a lot of stress during a long day.

When to Rebuild Your Tool

If you have air, oil, and no jams, you might have a broken seal. This sounds scary, but it is a fun DIY project. You can buy a kit with all the parts you need for a very low price.

Common Parts to Replace

| Part Name | When to Change It | My Experience |

| Piston Ring | When power feels weak | Very easy to swap out |

| Trigger Valve | If air leaks from trigger | Takes about ten minutes |

| Driver Blade | If the tip is chipped | Fixes frequent nail jams |

| Bumper | If the gun kicks back | Simple rubber part fix |

Replacing these parts is much cheaper than buying a new tool. I keep a spare kit in my drawer just in case. Most of the time, a quick clean and some oil are all you need to keep your Bostitch brad nailer running for years.

FAQs: Bostitch Brad Nailer Stopped Firing

Why is my Bostitch brad nailer not firing when I pull the trigger?

Most of the time, the air pressure is too low. Check your compressor and set it to 90 PSI. Also, make sure the safety nose is pressed firmly against the wood.

How often should I put oil in my pneumatic brad nailer?

I add two drops of tool oil every time I start a new project. This keeps the internal O-rings soft and prevents air leaks. It is a quick way to make your tool last longer.

Can I use any brand of nails in my Bostitch tool?

It is best to use high-quality 18-gauge nails that match your model. Cheap nails can vary in size and cause frequent jams. Stick to trusted brands to keep your drive path clear.