When I first set up my workshop, I had one big question — should I get a miter saw or a table saw first? I didn’t know it then, but that choice would shape how I worked with wood for years.

I’ve used both tools in many places — from small garage shops in the Midwest to open job sites under Arizona’s dry sun and Florida’s humid air that can rust blades fast. Each place taught me something new about how these saws handle when conditions aren’t perfect — and let’s be honest, they rarely are.

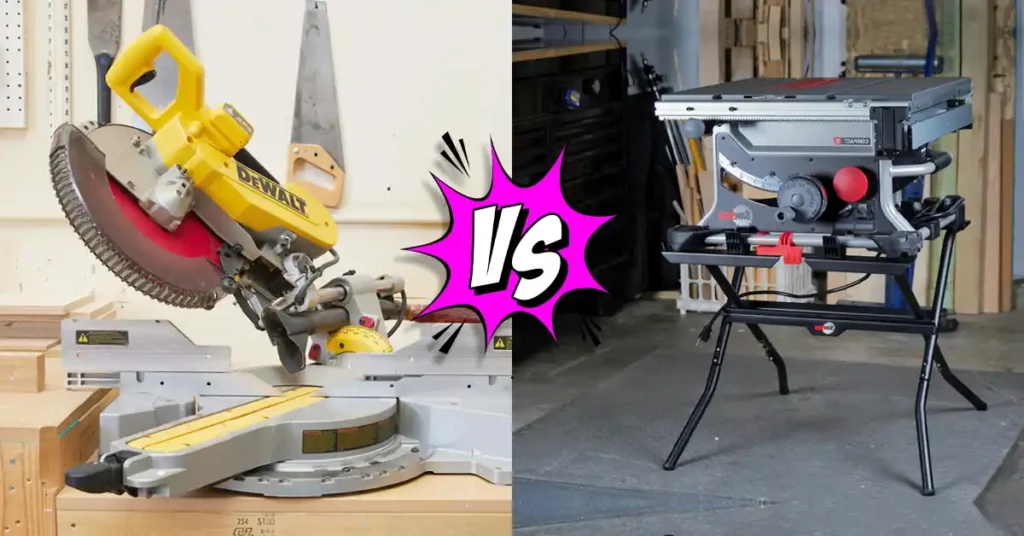

Both saws cut wood, but they don’t do the same job. A miter saw is great for clean, accurate angle cuts — like trimming doors or baseboards. A table saw is made for long, straight cuts that need steady control and power. They work best together, not against each other. Still, knowing their differences helps you pick the right one first.

If you’re building furniture, cutting trim, or just learning your way around a shop, this guide will help you see the real pros and cons of each saw — in plain, simple terms.

Table of Contents

Basic Function of Each Tool

When I first started woodworking, I thought a miter saw and a table saw were the same. Both had spinning blades and cut wood — simple, right? But once I used them side by side, I saw how different they really are. Each tool has its own job, and knowing that can save time and stop a few bad cuts.

Miter Saw — Precise and Purposeful

A miter saw is all about accuracy. It’s the tool I grab when I need clean, repeatable cuts — especially at angles. The blade sits on a pivot arm that swings down onto the wood. You can turn it for side angles or tilt it for bevels. That’s why it’s great for trim, molding, or framing.

When I was installing door casings in a Florida home, the miter saw made quick, perfect cuts with almost no setup. It’s light, portable, and ready to go in minutes — just set it on a stand, plug it in, and start cutting.

Still, a miter saw has limits. It can’t rip long boards or large sheets because the blade only moves across the wood, not through it. But for angled or finish cuts, nothing beats it.

Table Saw — Power and Straight-Line Control

A table saw is the workhorse of any shop. Instead of swinging down, its blade rises through a flat table. You push the wood through it, which gives strong, straight cuts. That’s why it’s perfect for ripping boards, cutting plywood, or building furniture panels.

When I built a workbench in my Minnesota garage, the table saw became my top tool. It sliced through thick boards with ease, even in cold weather. Once the fence was set, every cut came out smooth and even.

But it takes space. A table saw is heavy, needs a solid setup, and doesn’t move easily. Dust control also matters — especially in closed garages where sawdust piles up fast.

Technical & Practical Differences — Miter Saw vs Table Saw

After using both for years, I’ve learned that your choice depends on what you build most. Here’s how they stack up in real shop use.

Performance & Precision

A miter saw is best for fine, angled cuts — like crown molding or frames. It gives smooth joints that need little sanding. A table saw is made for straight, flat edges where precision over long cuts matters most.

Power & Cutting Capacity

Table saws are stronger. Most run on 15 amps or more, so they can handle thick hardwoods and large sheets. Miter saws are powerful too but meant for smaller, softer pieces. I once tried ripping oak on a miter saw — it didn’t like it one bit.

Portability

If you move between job sites or have a small garage, a miter saw is ideal. It’s light, compact, and quick to set up. A table saw, even a portable one from DeWalt or Ryobi, still needs a stable base and space to work safely.

Ease of Setup & Maintenance

A miter saw is easy to care for — keep the blade sharp, clean the rails, and check alignment. A table saw needs more upkeep. You’ll adjust the fence, keep the top rust-free, and lube the moving parts. In humid places like Florida, I always wipe mine down after use.

Safety Considerations

The table saw demands respect. Kickback can happen if your hands or feed angle are off. I always use guards and push sticks. A miter saw feels safer since its blade follows a fixed path, keeping your hands away from danger.

Learning Curve

The miter saw is easier for beginners. You line up the mark, pull the handle, and the job’s done. A table saw takes more learning — adjusting height, squaring the fence, and feeding boards safely takes practice.

Real-World Use in U.S. Conditions

- In Arizona’s dry air, table saw motors need frequent dust cleaning.

- In Florida’s humidity, miter saw blades can rust without a thin oil coat.

- In cold Midwest winters, both tools need a warm-up before full use.

Popular U.S. brands like DeWalt, Milwaukee, Ryobi, and Craftsman all make solid versions of both. The right one depends on how and where you work.

Comparison Table — Miter Saw vs Table Saw

| Feature / Factor | Miter Saw | Table Saw |

| Accuracy | Great for angled, detailed cuts | Best for long, straight cuts |

| Power Source | Corded or cordless | Mostly corded electric |

| Portability | Light and easy to move | Heavier but more stable |

| Safety | Low kickback risk | Needs care with large boards |

| Ideal Use | Trim, molding, framing | Large panels, ripping boards |

When to Use Each

Over the years, I’ve learned that knowing when to use each saw can make or break a project. Both tools have their strengths. Using the right one saves time, wood, and stress.

When to Use a Miter Saw

I reach for my miter saw when precision matters most. It’s perfect for cutting trim, molding, door casings, and picture frames — anything that needs clean, angled cuts. The blade moves smoothly and makes repeatable cuts easy.

When I was trimming windows in a humid Florida house, the miter saw saved me hours. It handled corners and baseboards perfectly without extra sanding. Its light weight also helped — I could move it from the driveway to the garage in minutes.

If you often take on home projects — like framing in Texas or adding molding in older homes — the miter saw is your best friend. It gives you clean results without needing much space.

When to Use a Table Saw

When I need to cut long boards or sheet goods, I turn to my table saw. It’s built for power and straight cuts — the kind you need for furniture, cabinets, or workbenches.

I remember building a workbench in my Oregon garage. The table saw ripped through thick maple with ease. Once I set the fence, every piece came out smooth and even. That kind of repeat accuracy is hard to beat.

If you build furniture, make cabinets, or do large DIY jobs, the table saw is essential. It takes more space and setup time, but the power and precision make it worth it.

Safety and Skill Level

Safety always starts with knowing how your tool behaves. Both saws can be safe if used the right way — but they need different levels of care and focus.

Miter Saw — Predictable and Beginner-Friendly

If you’re new to woodworking, start with a miter saw. The blade moves in one fixed path — straight down — so your hands stay out of danger. When I first started cutting trim in my Midwest garage, this saw gave me confidence. It felt steady and easy to control.

Still, safety gear is key. I always wear goggles to block dust, and in winter, I use thin gloves for grip. Keeping your stance balanced and workspace clear helps prevent slips or mistakes.

Table Saw — Demands Skill and Respect

The table saw is powerful — and it needs respect. Its open blade can cause kickback if you’re not careful. I’ve had close calls in my early days before I learned to use push sticks and featherboards every single time.

I always keep the blade guard on and feed wood smoothly without twisting it. In closed garages, especially in dusty states like Arizona, I use a mask and keep the air moving to stay safe.

Maintenance and Durability

Keeping your saws in good shape makes a huge difference — not only in how clean they cut but also in how long they last. I learned this the hard way after dealing with rusted blades and fences that slipped out of line. Each saw needs a bit of special care.

Miter Saw Maintenance — Clean and Consistent

A miter saw doesn’t need much, but a little care keeps it running for years. I always keep the blade sharp and the fence square. A dull blade burns wood fast and ruins clean cuts. After each job — especially in dusty places like Arizona — I use a small brush or compressed air to clear the rails and vents. It keeps the saw moving smoothly and the motor cool.

When I worked in Florida, humidity made me more careful. I wiped the blade and metal parts with a light coat of oil to stop rust. The plastic covers and rails also lasted longer when kept dry and clean.

Table Saw Maintenance — Alignment Is Everything

A table saw needs more upkeep, but it pays off every time you cut. I often check the blade alignment and fence setting. Even a tiny shift can throw off your cut. Every few weeks, I clean the tabletop and add a thin layer of paste wax. It keeps rust away and helps boards glide easily during cuts.

In cold garages, like my old one in Minnesota, I cover the saw in winter. The change in temperature can cause light rust, which takes time to remove. I also lube the gears and trunnions to keep the blade height and angle adjustments smooth.

General Care Across All Climates

No matter where you work — dry desert or humid coast — the basics are the same. Keep your tools dry, covered, and off the floor. I store both saws on raised stands, never directly on concrete where moisture gathers. A quick five-minute cleanup after each job saves hours of repair later.

Summary / Conclusion

After using both tools in all kinds of places, I’ve learned one thing — the miter saw and table saw aren’t rivals. They’re teammates.

The miter saw gives precision and control. It’s fast, light, and perfect for detailed work like trim, molding, and framing. The table saw gives power and straight-line accuracy. It handles large projects — furniture, panels, and flooring — with ease.

In my own shop, I use both. The miter saw handles the fine cuts, while the table saw shapes the big pieces that tie it all together. When you use each tool for what it’s made to do, you’ll work faster, safer, and with cleaner results every time.

FAQ — Miter Saw vs Table Saw

Can a miter saw replace a table saw?

Not really. A miter saw is for crosscuts and angles. A table saw is for long, straight cuts. They work best when used together.

Which is safer for beginners?

The miter saw. Its guided blade path keeps your hands clear and makes it easy to control. The table saw is safe too, but it takes more skill and focus.

Which tool makes cleaner cuts?

Both can make clean cuts when tuned right. The miter saw is great for trim and finish work. The table saw gives smooth, straight edges for panels and boards.

Do professionals use both?

Absolutely. Most carpenters and builders in U.S. shops keep both. The miter saw handles detailed work, and the table saw handles heavy cutting and joinery.