Ever wondered if a double bevel miter saw is really worth it? I sure have — especially when cutting trim in a hot, sticky Florida garage or shaping crown molding in a chilly Midwest basement.

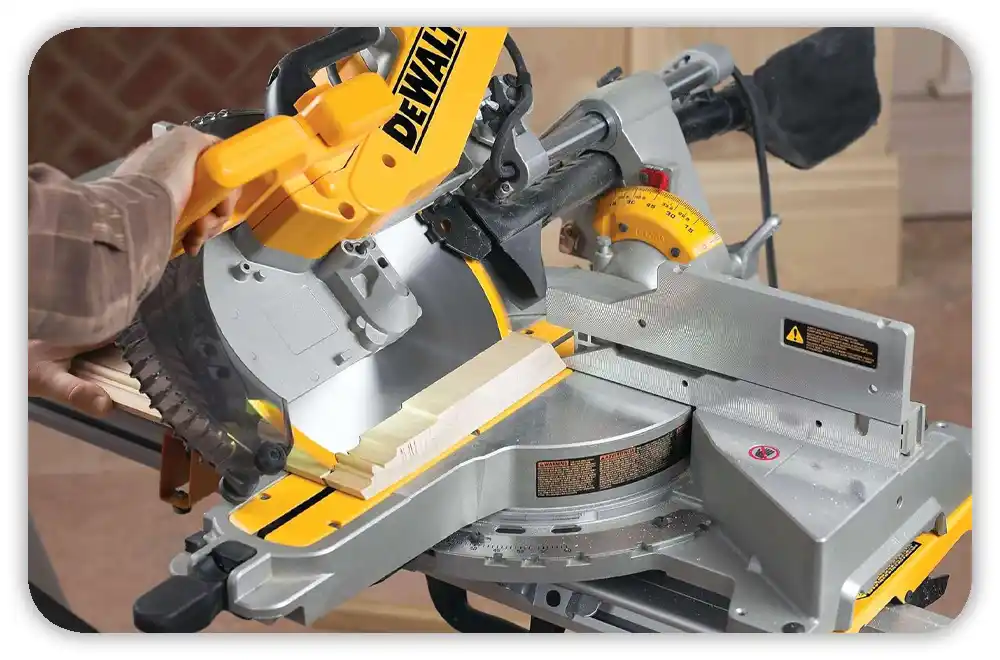

I’ve been there, balancing a DeWalt on uneven boards and brushing off sawdust between cuts. The truth is, the right saw can make or break your project.

After testing both single and double bevel miter saws side by side, here’s what I found about power, accuracy, comfort, and value.

Table of Contents

Quick Answer — Is a Double Bevel Miter Saw Worth It for You?

If you often cut trim, crown molding, or build cabinets, yes — a double bevel miter saw is worth it. It saves time, improves accuracy, and keeps your back happy. You won’t need to flip long boards all day.

But if you only do light framing or weekend DIY jobs, a good single bevel saw will work fine.

I learned this the hard way while trimming a full house in humid Florida. My single bevel saw did the job, but I had to flip every 12-foot baseboard for the next cut. By the third room, my arms were sore and my patience gone. When I switched to a double bevel, everything changed — the job flowed smoother, and every mirrored cut matched perfectly.

For pros or serious hobbyists, the upgrade pays off fast in time and precision. For casual users, it might be more saw than you need. The trick is to match your saw to your workflow, not just your budget.

What Is a Double Bevel Miter Saw and How Does It Work?

A double bevel miter saw has one big advantage — it tilts both left and right. That lets you make matching bevel cuts without flipping the board. You stay in your rhythm, and your setup stays steady.

When I upgraded from a single bevel, the difference was huge. Before, I’d make one cut, unclamp the board, flip it, line it up again, and hope both angles matched. With the double bevel, I just tilted the saw head to the other side and cut. Same accuracy — half the effort.

This feature shines in finish work: trim, furniture, picture frames, and crown molding. Whether you use a DeWalt, Bosch, or Makita, that two-way tilt makes life easier. Many U.S. carpenters love it for the accuracy and speed it brings to busy job sites.

The Difference Between Single and Double Bevel

A single bevel miter saw tilts one way — usually to the left. It’s lighter, simpler, and great for basic cuts. But when you need a mirrored bevel, you must flip the board. That’s fine for short trim, but awkward for long material.

A double bevel miter saw tilts both left and right. You can make mirrored cuts back-to-back without moving the board. When I worked in a small Chicago garage, this saved tons of space — no need to swing long boards around in tight spots.

What Makes a Double Bevel Saw Different in Real Use?

At first, I thought a double bevel was just a luxury. But after a few big trim jobs, I realized it’s a full workflow upgrade. The gains go beyond convenience — you get smoother cuts, fewer errors, and a serious boost in daily speed.

Efficiency and Workflow Benefits

When you stop flipping boards, you stop breaking your rhythm. On my first full-house install with a DeWalt DWS780, I cut hundreds of feet of crown and baseboard. The time savings were clear — about 20–25% faster by the end of the week.

- No more flipping or remeasuring

- Stop blocks stay in place

- Great for trim runs or cabinet jobs

This small change keeps your flow going — something every carpenter values after a long day.

Accuracy and Repeatability

Every time you flip a board, alignment can slip. Even a bit of dust under the board can throw off your cut. With a double bevel saw, the reference face never changes, so every mirrored cut stays perfect.

I’ve used this setup in Arizona’s dry heat and in cold Midwest basements. It always held its accuracy better than constant flipping ever did. When joints fit tight the first time, you save time, wood, and frustration.

Consistent setup equals consistent results. That’s the real advantage.

Ergonomics and Safety

Cutting long boards all day is tough on your body. A double bevel saw saves you from lifting and twisting heavy pieces. Your back and shoulders will feel the difference. When I worked on a remodel crew, those constant flips were brutal. Switching to a dual-bevel setup cut the strain in half.

Keeping the board still also makes the job safer. No awkward balance or shifting weight. Combine that with good habits — clear floors, steady footing, and dust control — and you’ll work faster and safer.

It’s not just about speed. It’s about comfort, safety, and better long-term results.

What Are the Downsides of a Double Bevel Miter Saw?

As much as I love using a double bevel miter saw, it’s not perfect. The biggest trade-offs are cost, weight, and maintenance. These saws are heavier, pricier, and need more care to stay aligned. If you only build decks or do the occasional home project, the extra features might not be worth it.

When I first upgraded, I noticed two things — my wallet got lighter, and so did my patience when moving it around. It’s a great tool, but not one I’d call portable. Let’s look at what those trade-offs mean in real use.

Cost Comparison

Here’s where the math hits. A good single bevel saw costs about $250 to $400, depending on the brand and size. A double bevel model starts around $450 and can reach $700 or more. Go for pro-grade tools like the DeWalt DWS780, Bosch GCM12SD, or Makita LS1019L, and you’ll likely spend $800 or higher.

When I bought my first dual-bevel saw, the price hurt at first. But once I started full-house trim jobs, the time savings made it worth it. If you only build once in a while, that extra money may not pay off.

Portability and Space

Most double bevel saws aren’t light. They weigh between 55 and 70 pounds, making them harder to move from site to site. I’ve hauled mine up and down stairs more times than I care to count — it’s not fun after a long workday.

They also take up more bench space. For example, the Bosch GCM12SD needs extra clearance behind it, while a SKIL MS6305-00 fits tighter shops. In my small Chicago garage, I had to rearrange my whole setup to make room.

If you work from one fixed shop, it’s no big deal. But if you’re a mobile contractor, weight and size matter.

Maintenance and Calibration

A double bevel saw has more moving parts, and every one needs to stay in line. Over time, vibration or rough transport can knock it slightly out of square. That small shift can throw off your bevel cuts.

I’ve learned to check mine every month with a square and reset the bevel stops if needed. It’s a quick job but easy to forget until joints stop fitting tight.

Dust and humidity also play a role. In dry states like Arizona, fine dust builds up fast. In humid states like Florida, rust can creep in if you don’t clean it. Keeping rails and pivots wiped down makes a big difference.

So yes — these saws deliver precision, but they need more care to keep it that way.

When Is a Double Bevel Miter Saw Worth the Investment?

Whether a double bevel saw is worth it depends on what you cut, how often, and how much your time is worth. After years of switching between framing and finish work, I’ve learned that the payoff depends on your workflow.

For Professional Carpenters and Trim Installers

If you do trim, crown molding, or cabinetry every day, a double bevel saw is a time-saver. You can make mirrored cuts, keep boards in place, and work faster.

On a big trim job I did in the Carolinas, I saved hours each day just by not flipping baseboards. The precision and speed paid for the saw in a few weeks.

For Serious Woodworkers and Remodelers

If you love building furniture or detailed trim, a double bevel makes the process easier and more fun. You spend less time flipping boards and more time focusing on clean angles.

When I built a custom entertainment center in my home shop, I noticed how relaxing it felt. No remeasuring, no guessing which way to tilt — just smooth, accurate cuts every time.

For dedicated builders, a double bevel turns tricky angles into muscle memory.

For Homeowners and DIYers

If you’re only doing light framing or home repairs, a single bevel or sliding saw makes more sense. You’ll get solid performance without the extra weight or cost.

That said, if you enjoy detailed projects and plan to do more finish work, a double bevel can be a great upgrade. It makes your cuts faster and your results cleaner.

For casual DIYers, it’s a nice bonus — not a must. For frequent home renovators, it’s worth every penny.

Sliding vs. Double Bevel — Which Upgrade Comes First?

If you’re torn between a sliding saw and a double bevel, here’s the truth: most people benefit more from a sliding model first. A sliding saw expands your cutting width — a major plus for shelving, flooring, and framing projects.

I learned this while cutting 1×12 pine shelves in a small Raleigh shop. My fixed miter saw couldn’t handle the width, but a sliding model sliced right through. Later, when I added the double bevel, it boosted my accuracy more than my capacity.

Sliding Mechanism Benefits

A sliding saw moves the blade forward and back on rails. That simple action doubles your cutting width.

- Great for flooring, framing, and shelving

- Cuts wide boards without needing a table saw

- Ideal for mixed-use workshops and contractors

If you often cut wide material, a sliding saw is the first real upgrade that changes what your tool can handle.

Double Bevel Benefits

A double bevel doesn’t add reach — it adds precision. It’s made for detailed or repetitive work where flipping slows you down.

In short: sliding boosts cutting width, while dual-bevel boosts accuracy and comfort.

If you care more about mirrored angles and speed than width, the double bevel is your next step.

Real-World Example

Here’s a simple example: when I was cutting 1×12 shelves, a sliding single-bevel saw handled them perfectly. But once I started making crown molding and picture frames, I switched to a double bevel. Each upgrade solved a different problem.

So if you’re improving your setup one step at a time — go sliding first for capacity, then double bevel for precision.

What Features Should You Look for in a Quality Double Bevel Saw?

Not all double bevel miter saws are the same. After testing many, I’ve learned that the difference between a good saw and a frustrating one comes down to stability, accuracy, and design. The best saws don’t just cut straight — they stay straight after hundreds of cuts.

When I shop for a new saw, I ignore flashy specs and focus on feel. I check how smoothly the head tilts, how firmly the bevel locks, and whether the fence stays solid under pressure. These small details decide if your saw lasts or drifts out of line after a few months.

Core Quality Factors

Here’s what I always check before buying or recommending a double bevel saw:

Rigid fence alignment: A solid fence keeps boards stable and angles true. If it flexes, accuracy suffers. I’ve used cheap saws where a little pressure moved the fence — not fun when cutting crown.

Smooth bevel action with positive stops: The head should tilt easily and lock tight at common angles like 22.5°, 45°, and 90°. Smooth beveling saves time and prevents errors.

Reliable cutline guide: I prefer the XPS shadow line over lasers. It’s brighter, more accurate, and stays aligned even in bright light or outdoor work.

Effective dust collection: Whether you’re in a clean shop or a dusty garage, dust control matters. It protects moving parts and extends tool life.

I’ve worked with saws that locked stiff or lost calibration after a week — it kills your workflow. Once you use a saw with smooth stops and a true fence, you won’t go back.

Focus on precision and build quality — not power ratings.

Trusted Models in 2025

Here are saws I’ve personally used or seen perform well on U.S. job sites this year:

- DeWalt DWS780 — My go-to for years. The XPS shadow line is spot-on, and it’s built tough for daily trim work.

- Bosch GCM12SD — The Axial-Glide system saves space, great for small shops or garages.

- Makita LS1019L — Excellent dust control and smooth rails. A quiet, refined option for shop work.

- SKIL MS6305-00 — Budget-friendly with dual bevel and solid accuracy for homeowners.

Each has strengths. In tight spaces, that Bosch glide system shines.

Buy for your workflow — not the brand name.

How Do You Keep a Double Bevel Saw Accurate Over Time?

A double bevel saw is only as good as its calibration. Even the best models can drift after heavy use or travel. Dust, vibration, and humidity all take their toll. Regular care is what keeps your saw cutting like new.

When I worked in Florida, moisture caused light rust that threw off my bevels. In Arizona, fine dust crept into every joint. The secret isn’t endless adjustment — it’s consistent, simple maintenance.

Routine Maintenance Tips

Here’s what I do after every big project or once a week during busy season:

- Clean rails and joints after each use. Wiping off fine sawdust reduces friction.

- Use PTFE spray, not oil. It keeps slides smooth without trapping dust.

- Cover and store indoors. Cold garages and humid shops can cause corrosion.

Even one minute of cleaning after work extends your saw’s life. I’ve seen neglected saws lose precision fast, while my well-kept DeWalt has stayed square for nearly ten years.

Simple upkeep beats constant recalibration.

Calibration Checks

I check my saw’s accuracy once a month or after any move. My quick checklist:

- Check fence squareness with a combination square.

- Test both left and right bevel angles.

- Adjust bevel stops if you notice even a slight drift.

It takes only ten minutes and prevents costly mistakes later. Calibration drift is normal — staying ahead of it keeps your cuts perfect.

Regular checks stop small errors from turning into big ones.

Environmental Impact

Where you work affects how your saw ages. Here’s what I’ve seen across the U.S.:

- Humid states (Florida, Texas): Moisture causes rust and sticky pivots. A light corrosion protector helps.

- Dry climates (Arizona, Nevada): Dust infiltration is common. Blow out joints with air or a soft brush.

- Cold states (Minnesota, Michigan): Avoid freezing storage. Condensation can harm bearings when metal warms up.

Each climate brings challenges, but the fix is simple — clean, protect, and store smart.

Treat your saw like a precision tool, and it’ll stay accurate for years.

Real-World Verdict — When a Double Bevel Miter Saw Truly Pays Off

After years of using both single and double bevel saws, I’ve learned it’s not about owning the fanciest tool. It’s about using the right one for your work. For pros and serious builders, a double bevel pays off fast. For casual users, it may be more than you need.

When I started full-time trim work, my double bevel became essential. But when I helped friends with basic framing, their single bevels did fine. It all depends on how often you need mirrored accuracy.

If your projects demand precision and volume, it’s a must-have. If not, spend the money on better blades or dust control.

Bottom-Line Recommendations

Here’s how I break it down:

- Pros and Contractors: Absolutely yes. Time saved on mirrored cuts pays for the upgrade in weeks.

- Hobbyists and Remodelers: Yes, if you do detailed work and want consistent accuracy.

- DIYers and Homeowners: Not essential. A single-bevel or sliding saw covers most home projects.

When people ask if it’s worth it, my answer is simple: only if your workflow truly benefits.

Match the tool to your needs, not your wish list.

Rule of Thumb

Here’s how I explain it to anyone standing in the tool aisle:

“If you flip boards more than a dozen times a day, it’s worth the upgrade. If not, spend that money on a better blade or single-bevel saw.”

That question has saved plenty of people from buyer’s regret — and helped others choose right the first time.

Precision tools pay off when your work demands them — not because they look professional.

FAQs — Quick Voice Search Answers

After years of cutting trim, molding, and frames, I’ve heard these questions more times than I can count.

Here are quick, clear answers — based on real hands-on work.

What’s the main benefit of a double bevel miter saw?

Speed and accuracy. It tilts both left and right, so you can make mirrored cuts without flipping the board. That saves time, avoids mistakes, and keeps your workflow smooth — especially on trim jobs.

Is a double bevel saw better for crown molding?

Yes, it is. When cutting crown, you can keep the molding flat on the saw table instead of flipping it around. That means consistent angles and perfect mirrored cuts every time.

Do I need a double bevel for DIY projects?

Not really. For decks, shelves, or framing, a single bevel or sliding miter saw works fine. A double bevel shines when precision and repetition matter — like finish trim or furniture work.

How long does a double bevel saw last?

With care and calibration, a good one can last 10 years or more. My DeWalt DWS780 has been cutting true for nearly a decade. Keep the rails clean, store it indoors, and it’ll stay sharp for years.

Final Take — The Smart Buy for Your Workshop

After all the sawdust and long days, here’s what I’ve learned — a double bevel miter saw isn’t for everyone, but when it fits your work, it’s worth every penny.

I still remember my first big trim job in a humid Florida house. My single bevel saw worked, but I kept flipping long baseboards and fighting angles. When I switched to a double bevel, everything changed — the work flowed faster, and the finish looked cleaner.

If you’re a pro carpenter or a serious hobbyist who builds furniture, cabinets, or detailed trim, this saw will earn its keep fast. It saves time, improves accuracy, and cuts fatigue during long days on site.

But if you’re a casual DIYer, doing the odd framing or shelf project, a single bevel or sliding saw gives you better value. You’ll still get great cuts without the higher cost or extra weight.

Whether you’re in a small Midwest garage or a busy Texas workshop, the key is balance — buy the saw that fits your work, not your wish list.

In the end, a double bevel saw isn’t just an upgrade. It’s a smoother way to work. Treat it well, keep it calibrated, and it’ll reward you with clean, perfect cuts for years.

That’s the real value — not what it costs, but what it saves you in time and effort.