It’s Sunday afternoon. The garage is half-lit. You need one wire joined—just one—and your soldering iron is missing, dead, or loaned out “forever.” I have been in this exact spot more times than I care to admit.

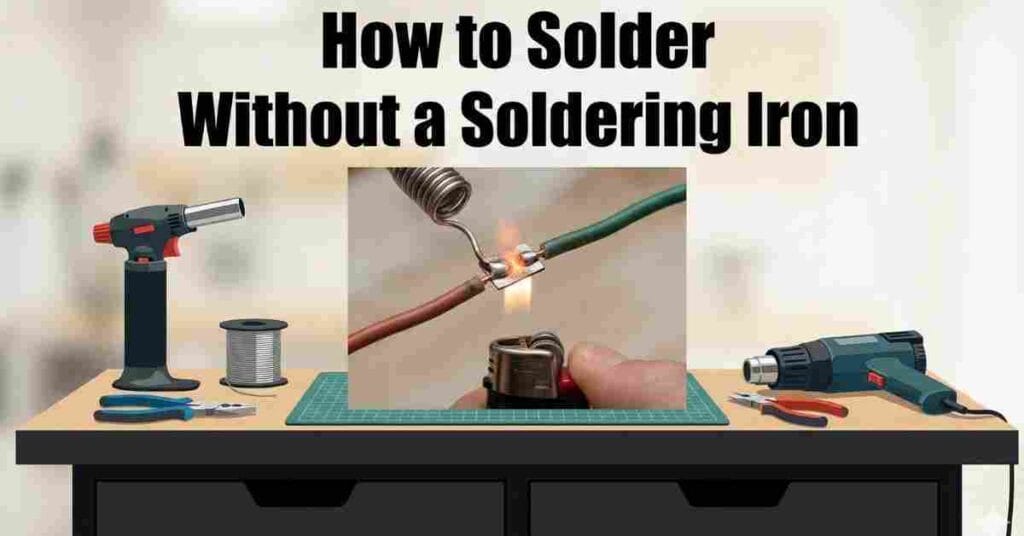

You stare at the broken wire. You check your pockets for a lighter. You wonder if this is a good idea. Before you ruin a perfectly good cable, let’s talk about what actually works. This guide covers temporary fixes and field repairs, not permanent solutions for critical tools.

Table of Contents

When Soldering Without an Iron Makes Sense (And When It Doesn’t)

Before grabbing a lighter or heat gun, it helps to know when this is smart—and when it’s asking for trouble. Not every wire is a candidate for a quick hack.

Situations where alternatives can work

I usually give the green light for low-stakes, low-voltage repairs. If I’m fixing a speaker wire in my car or patching an LED strip, I’m less worried.

These methods also work for field fixes when power isn’t available. If you are stuck on a roadside or a campsite, function matters more than perfection. It is also fine for short-term connections during testing.

Situations where you should stop and wait

Never try these hacks on high-current wiring. This includes appliances, power tools, or anything in your home’s breaker box.

Safety-critical systems are also off-limits. I would never patch a brake controller or HVAC board this way. If it involves your safety, put the lighter down.

Finally, avoid this for anything that must pass code. In the US, the NEC (National Electrical Code) and OSHA have strict standards. They expect proper tools and controlled heat, not improvisation.

What Solder Actually Needs to Work

Solder doesn’t care about your situation or your feelings. It only responds to three physical things: heat, clean metal, and timing.

The three non-negotiables

First, you need heat. It has to be enough to melt the solder instantly, not just make it soft and chunky.

Second, you need clean metal. Oxidation is the enemy. If the wire is dirty, the solder will just ball up and roll off.

Third, you need control. You have to apply heat without melting the insulation jacket off the wire.

Why most “hacks” fail

I’ve seen plenty of bad repairs. The most common issue is uneven heat, which causes “cold joints.” These break easily.

Open flames are also tricky because they dirty the copper. They leave soot that stops the bond. Without temperature control, it is all just guesswork.

Method 1: Using a Heat Gun (The Least Bad Option)

If you already own a heat gun—maybe a Milwaukee, DeWalt, or Craftsman—this is the closest thing to doing it right. It is my preferred method if an iron isn’t around.

How it works in practice

Set your heat gun to high. You want a focused stream of hot air. Twist your wires together securely first.

I like to wrap the solder around the joint before heating. Then, I bring the heat gun in close. It takes longer than an iron, but it is much safer than a flame.

What to watch out for

The biggest risk here is collateral damage. A heat gun blows hot air everywhere, not just on the wire.

I have melted wire insulation six inches away by accident. If you have heat-shrink tubing nearby, keep it far away until you are ready. Otherwise, it will shrink before you even get it on the wire.

Method 2: Using a Lighter or Torch (Emergency Only)

This is the classic “parking lot fix.” It works—but barely—and only if you are very careful. I only do this if I have zero other options.

When people try this

I see this most often with automotive wiring. Someone cuts a wire installing a stereo and needs a quick fix.

It also happens at events or parties. A speaker wire snaps, and someone pulls out a BIC lighter. It is purely a survival tactic.

Common mistakes

The biggest mistake is burying the wire in the flame. This covers the copper in soot. Solder hates soot.

Another issue is burning the flux. Flux helps solder flow, but a lighter burns it off in a second. You end up with a brittle, ugly lump of metal.

Method 3: Solder Paste and External Heat

Solder paste helps—but it’s not magic. It is a mix of solder powder and flux. I keep a syringe of it in my portable kit just in case.

Why paste changes the odds

Paste has built-in flux. This improves “wetting,” which is just a fancy word for the solder sticking to the wire.

It also tends to melt at a lower temperature than solid wire solder. This makes it easier to use with less intense heat sources like a heat gun.

Realistic outcomes

You will get better joints with paste than with plain wire solder. The flux does a lot of the heavy lifting for you.

However, it is still inconsistent. Without an iron to touch the joint directly, you might leave pockets of unmelted paste. It is best for small electronics repairs, not thick power cables.

Method 4: Mechanical Alternatives That Skip Solder

Sometimes the smartest move is not soldering at all. Honestly, I use these mechanical fixes more often than I use a lighter.

Options that actually hold up

Crimp connectors are great if you have the pliers. They crush the metal together for a solid bond.

WAGO lever connectors are my absolute favorite. You just flip a lever, insert the wire, and clamp it down. They are huge in Europe and are finally getting popular here in the States.

For simple indoor stuff, wire nuts work fine. They are ugly, but they conduct electricity.

Why pros choose these instead

The main benefit is that no heat is required. You don’t have to worry about burning your car’s carpet or melting plastic.

They are also often code-friendly when used correctly. A proper crimp is better than a bad solder job. Plus, in a freezing cold garage in January, crimping is much faster.

Why These Fixes Fail Over Time

If a joint looks dull, cracked, or stiff—it’s already on borrowed time. I treat all these methods as temporary.

Long-term risks

Vibration is the killer. If the wire is in a car or a tool, a stiff solder joint will eventually crack.

Oxidation creep is another issue. If the seal isn’t air-tight, rust gets in. Eventually, the connection fails.

Signs it’s time to redo it properly

Watch for flickering power. If your lights dim when you wiggle the wire, the joint is bad.

Intermittent connections are annoying and a sign of failure. If the wire feels warm to the touch, cut it immediately. That means there is resistance, and resistance causes fire.

The Right Way Forward

Every workaround has an expiration date. Once I get my tools back, I always go back and fix my emergency hacks.

What to fix later

I cut off the old, messy joint. Then, I re-solder it with a temperature-controlled iron.

I also replace any damaged wire ends. If the insulation got singed by the lighter, I cut that part out. I always finish with proper heat shrink for strain relief.

Tools worth owning

If you do this often, get an entry-level soldering station. You don’t need a $300 unit, but a $40 station is better than a stick iron.

Get a flux pen and a tip cleaner. And please, buy decent wire strippers and crimps. Your future self will thank you.

Final Reality Check

You can solder without a soldering iron—but that doesn’t mean you should make a habit of it.

I have used a lighter in a pinch, and it got me home. But I wouldn’t trust my house wiring to a BIC lighter. Know your limits, stay safe, and get the right tool when you can.

FAQs – How to Solder Without a Soldering Iron

How can you solder without a soldering iron at home?

You can solder without a soldering iron by using a heat gun, lighter, or torch. These tools can melt solder, but control is low, so this works best for quick fixes.

Is it safe to solder wires without a soldering iron?

Soldering without a soldering iron is only safe for low-voltage wires. Open flames add risk, so wear gloves and keep heat away from insulation and skin.

What is the best alternative to a soldering iron?

A heat gun is the best soldering iron alternative. Brands like Milwaukee or DeWalt give steady heat and reduce wire damage compared to lighters or torches.

Can solder paste work without a soldering iron?

Solder paste can work without a soldering iron if you add heat from a heat gun. It melts faster than solid solder and helps joints stick better.

When should you avoid soldering without an iron?

Avoid soldering without a soldering iron on high-power wires or home wiring. These joints can fail and may not meet safety rules like OSHA or NEC standards.