Last weekend was a headache. I was in the garage trying to fix a trailer light connector. It was cold out. I had my coffee, my tools, and a plan.

But the solder just sat there. It balled up like a drop of mercury. It rolled right off the copper wire and hit the floor. It mocked me.

I stared at the wire. I may have said a few bad words. If you are stuck like this, I get it. It is frustrating.

Usually, it is not you. It is just physics working against you. It is dirt, lack of heat, or the wrong metal mix. Let’s sort it out.

The Invisible Enemy: Dirt and Grime

You cannot glue metal to dirty metal. It just won’t work. Even if the wire looks clean, it might be lying to you.

Scrub It Until It Hurts

Copper oxidizes fast. That is just a fancy word for rust. A clear skin forms on the wire. Solder cannot grab onto that skin. It needs raw, pink metal.

I use a simple Scotch-Brite pad. I scrub the wire until it looks brand new. If the wire is old and black, like on a vintage car, I use a knife. I scrape it until I see fresh copper.

Oil is a killer too. One time, I tried to solder after eating chips. The salt and grease on my fingers ruined the joint. Now, I wipe everything with rubbing alcohol first.

Tinning the Tip

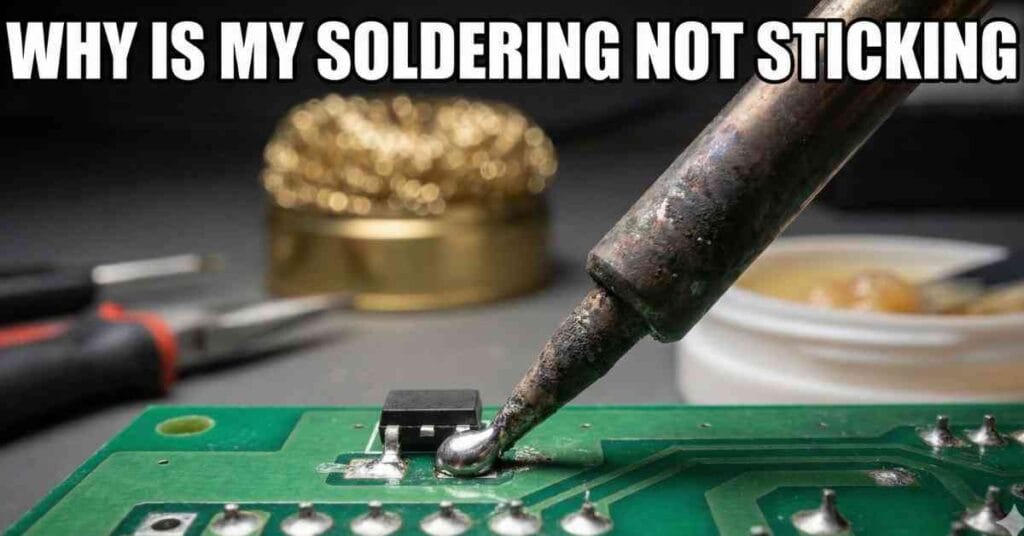

Your iron tip matters. If it looks black or rusty, it is dead. Heat cannot get through the rust. The solder will just blob up and fall off.

You have to “tin” the tip. I melt a big glob of fresh solder on the tip. I let it sit for a second, then wipe it off. It should shine like chrome.

I stopped using wet sponges years ago. The cold water shocks the metal. I use a brass wool ball now. It scrapes the gunk off but keeps the heat high.

Is It Hot Enough?

Heat is tricky. It is not just about the setting on the dial. It is about how the heat moves.

The Cold Joint Mess

A bad joint looks ugly. It is dull and grainy. We call this a “cold joint.” It is brittle. It will crack when you hit a bump in the road.

This happens if the wire moves while cooling. Or, the iron was too weak. A good joint looks smooth and shiny. It should slope down like a tent, not sit like a ball.

Size Matters

I used to use a cheap $15 pencil iron. It was fine for small toys. But then I tried to solder a thick 10-gauge ground wire. It was a disaster.

The thick wire sucked the heat away. My little iron could not keep up. It was like trying to melt an ice cube with a match. The wire stayed cold.

I finally bought a real station. I use a Weller, but Milwaukee makes good cordless ones too. For big wires, I set it to 750°F. You need that power to push heat fast.

The Flux and the Metal

Flux is a sap that cleans the metal when it gets hot. You need it. Without flux, solder is just hot, sad metal.

The Plumbing Trap

Don’t be like me. I once ruined a guitar pedal with acid core solder. That stuff is for fixing copper pipes under your sink.

Acid eats the metal to make a seal. On electronics, it eats the wires. It causes rot weeks later. Check your roll. You need “Rosin Core.”

Rosin is safe for wires. It smells like pine trees when it smokes. If you see “Acid” on the label, keep it away from your electronics bench.

The Lead-Free Struggle

Most shops like Home Depot sell “Lead-Free” solder now. It is safer, sure. But it is a pain to use. It melts at a much higher heat.

It feels gummy. It does not flow like water. If you are new, it is hard. If you can, find a roll of 60/40 lead solder online.

The lead mix flows smooth and fast. It melts cooler. It makes learning way easier. Just wash your hands after you touch it.

Stay Safe

I have a scar on my thumb to prove this part. Molten metal finds bare skin fast.

Smoke and Eyes

That smoke isn’t just steam. It is chemical gas. It makes me cough. I put a small desk fan next to my hand.

I point the fan away from me. It sucks the smoke out. I also open the garage door a bit. Fresh air is your friend.

And please, wear glasses. Flux can pop and spit. A hot speck in the eye is a bad day. My safety glasses hang right on my lamp so I grab them every time.

Conclusion

If it won’t stick, stop. Don’t force it. Clean the wire again. Turn up the heat. Check your tip.

Soldering is a feel thing. It takes time. My first few tries were ugly. But once you feel the solder flow, you will get it.

Go grab some sandpaper. Clean that tip. Give it one more shot. You can do this. Let me know if a fresh tip fixed the issue!

FAQ – Why Is My Soldering Not Sticking

Why does my solder ball up instead of sticking?

This happens when the metal is dirty or rusty. Solder cannot bond to oil or grime. Scrub the wire with steel wool until it shines bright pink.

Do I really need to use flux for soldering?

Yes, flux is key. It cleans the metal as it heats up. Without flux, solder will not flow right. Your joint will be weak and brittle.

What temperature should I set my soldering iron to?

For most wires, set it between 650°F and 750°F. If the tip is too cold, the solder clumps. If the wire is thick, you need more heat to make it stick.

How do I clean a black soldering iron tip?

A black tip is dirty. Clean it with brass wool while it is hot. Then, melt fresh solder onto it to seal it. This keeps the heat flowing well.

Why is my lead-free solder hard to use?

Lead-free solder needs more heat than old lead solder. It does not flow as smooth. Turn up your iron a bit and give it more time to melt into the joint.