Ever had your DeWalt miter saw stop sliding smooth right when you needed a clean crosscut? I’ve been there — in a humid Florida garage with sticky sawdust on the rails, and in a cold Midwest shop where the grease turns stiff overnight. A smooth slide can make or break your cut.

In this post, I’ll compare sliding miter saws from DeWalt, Milwaukee, and Craftsman. You’ll see which ones glide the best, which need more care, and how to fix that sticky slide fast. These are my real-world notes after testing them side by side.

Table of Contents

Why Your DeWalt Miter Saw Stops Sliding Smoothly

I’ve had my DeWalt miter saw stop sliding more times than I’d like to admit. The first time it happened, I thought the rails were bent or the bearings were bad. But it was just a sticky mix of sawdust and dried grease after a long week cutting pine trim in my Florida garage.

A jammed or rough slide usually comes from three things — friction, misalignment, or a lock that’s still on. Once you know how the slide works, fixing it is simple. You don’t need new parts or a full teardown.

What the Sliding Mechanism Does

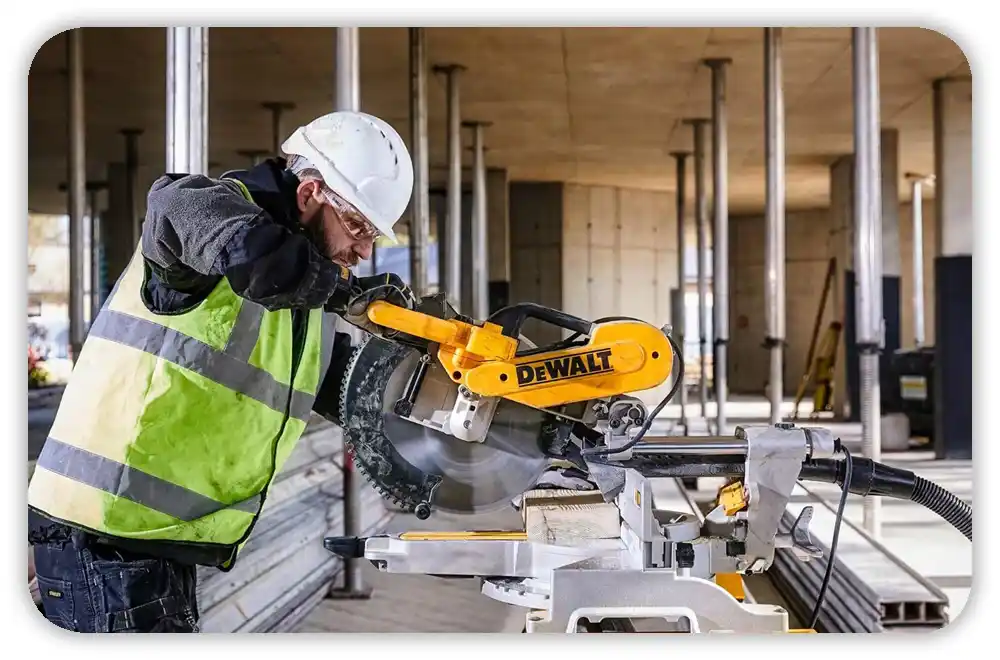

The slide makes a miter saw different from a chop saw. Instead of cutting only narrow boards, those rails and bearings let the saw head move forward for wide cuts. Older DeWalt saws like the DW models use one rail, while newer ones — like the DWS779 and DWS780 — use two polished steel rails that glide on bushings or bearings.

When those rails stay clean, the head moves like it’s on ice. But if dirt, resin, or rust builds up, it drags and grinds. A smooth slide isn’t just nice — it keeps your cuts straight and safe. If the saw hesitates mid-cut, the blade can twist or bind.

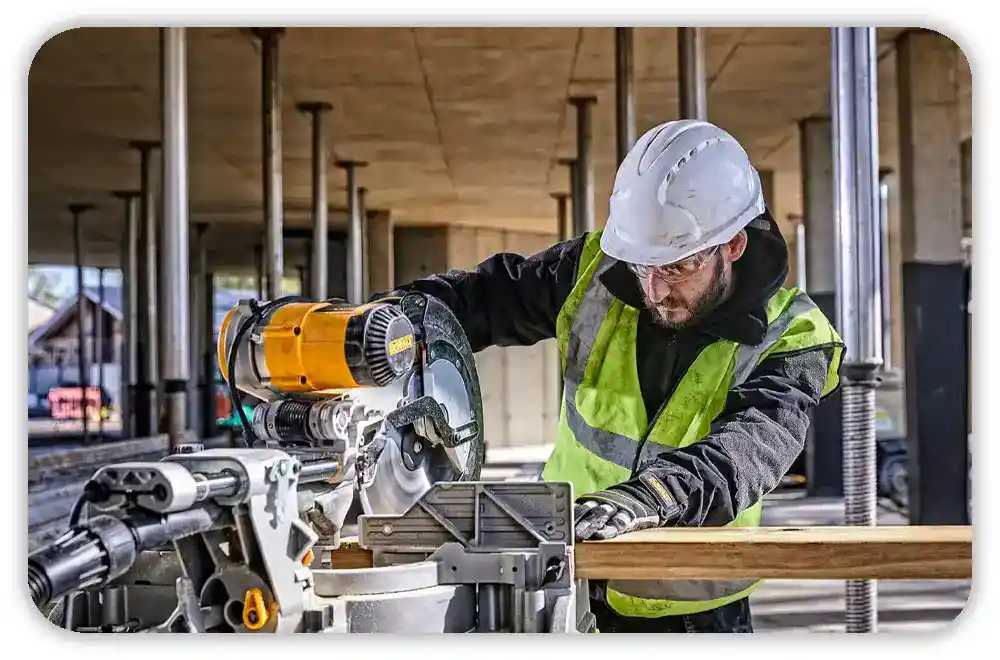

A clean, even slide means straighter cuts and safer work — every time.

Common Causes of Slide Failure

After using my saws in every kind of U.S. weather — humid Florida summers, icy Midwest winters, and dusty Arizona garages — I’ve learned most slide issues come from the environment, not the machine.

Here are the main culprits:

- Dust and resin buildup — Sawdust mixed with pitch makes a sticky paste.

- Locked rail knob — Easy to forget, easy to fix.

- Old grease — Heat or cold turns it thick and gummy.

- Bent rails or worn bearings — Usually from a fall or hard hit.

- Guard or fence interference — The guard or tall fence can catch during bevel cuts.

Each one can make your saw feel rough or stuck. Most are quick fixes once you spot the cause.

Quick Checks Before You Grab a Wrench

Before cleaning or taking anything apart, run these simple checks. They take less than five minutes and fix about half of all sliding problems.

Is the Rail Lock Knob On?

This one catches me all the time. The rail lock knob — near the back of the saw — keeps the head still during transport. If it’s even a little tight, the head won’t move.

Turn it counterclockwise to unlock. On my DWS780, I marked “Lock” and “Unlock” with a bit of paint so I can see it fast. Always check this first — it’s the #1 reason for a stuck slide.

Is the Head Lock Pin Engaged?

DeWalt’s head lock pin holds the saw head down for storage. If it’s half-in, it can feel like the slide is jammed.

Push down on the handle, pull the pin out, and let the head rise. The motion should be smooth. I once spent 10 minutes tugging before I realized the pin was halfway in — don’t make that mistake.

Are Guards or Fences Blocking the Slide?

If your saw still won’t move, check for simple collisions. Lower the head, unplug the saw, and move it forward and back slowly. Watch for anything catching.

Pull out the sliding fences before bevel or compound cuts — the motor or guard can hit them. Also check if the dust tube rubs the frame, especially on older models.

Always test for obstructions before cleaning. Sometimes, it’s just a fence in the wrong spot.

Cleaning and Lubrication — The Real Fix

If you’ve unlocked everything and it still feels stiff, it’s time for a deep clean. Most sliding issues come from dust and old grease. A quick cleaning and dry lube usually fix it fast.

Safe Cleaning Steps

Here’s my go-to process:

- Unplug the saw or remove the battery.

- Blow off dust with air or a shop vac.

- Wipe the rails with mineral spirits or a degreaser to cut resin.

- For light rust, use #0000 steel wool and a few drops of WD-40.

- Dry it clean with a cloth before adding any lube.

I’ve done this in hot Texas shops and cold Michigan garages — clean metal always slides better.

Which Lubricant Works Best

Not all lubricants are good for sawdust. Here’s what I’ve tested and what works best:

| Lubricant Type | Pros | Cons | Best Use |

| PTFE/Teflon dry lube | Dust-resistant, clean | Needs reapplying often | Woodworking shops |

| Graphite spray | Smooth, heat-safe | Messy black residue | Outdoor or metal cutting |

| Oil or grease | Long-lasting | Attracts dust, gums up | Avoid on exposed rails |

For woodworking, PTFE dry spray wins every time. My picks are WD-40 Specialist Dry Lube, Blaster Dry Lube, or CRC Industrial Dry PTFE.

Pro Tip for Smooth Glide

Shake the can well and spray a light coat on both rails. Move the saw head forward and back 10–15 times to spread it evenly. Wipe off extra residue — you want a dry slide, not a wet one.

I reapply monthly in my Midwest shop and more often in Florida’s humidity. The result? No drag, no grind — just a clean, effortless glide.

A little cleaning and the right lube can make your DeWalt miter saw feel brand new again.

Advanced Fixes — When Cleaning Doesn’t Solve It

Sometimes, even after a full cleaning and dry lube, your DeWalt miter saw still won’t slide right. That’s when I know something deeper is off — maybe a rail is out of line, a bearing is worn, or the carriage has too much play. These checks take patience, but they can save your saw from costly repairs.

If your slide still feels gritty, binds halfway, or moves unevenly, it’s time to dig deeper.

Check Rail Alignment with a Framing Square

This is my go-to test when the saw feels tight in one spot but loose in another. If the rails aren’t parallel, the head binds as it slides.

Here’s how I check it:

- Unplug the saw and lock the head down.

- Place a framing square flat on the table, one edge against the fence.

- Bring the blade down so the flat part (not the teeth) touches the square.

- Slide the head forward slowly and look for gaps or rubbing.

If the blade presses harder as you move forward, the rails are converging. If a gap opens, they’re spreading. Either way, the rails aren’t parallel.

A light tap with a rubber mallet on the rear mounting block can fix it. Go slow — even a millimeter too much makes things worse. After years of use, a tiny tweak often brings your saw back to perfect tracking.

Diagnose Carriage Slop or Side Play

Once, my DeWalt saw wouldn’t slide smooth, and the real issue was side play. The saw head wobbled left and right at full extension. That little bit of play ruins accuracy fast.

To test it, extend the saw fully and move the handle side to side. You shouldn’t feel any movement. If you do, the carriage set screw needs a small adjustment.

On the DWS780 and DWS779, there’s a tiny Allen screw inside the carriage. It controls tension on the bushings. Turn it clockwise 1/8 turn at a time, then test the slide. If it binds, back it off slightly.

You want the sweet spot — no play, smooth glide. Once it’s right, your saw feels solid again, with clean, square cuts every time.

Check for Bearing or Bushing Wear

If cleaning and tuning don’t help, the bearings may be worn or seized. I learned this after ignoring a faint grinding sound that turned into a full jam.

Look and listen for these signs:

- Grinding or scraping when sliding the head

- A gritty or “notchy” feel in certain spots

- Vibration through the handle

Inspect the rails and bearing housings. Any rust, grooves, or collapsed bearings mean it’s time for replacement.

You can find parts easily on DeWalt ServiceNet or eReplacementParts.com — just match your model and type number.

With fresh bearings, your saw should glide smooth, quiet, and steady again.

Model Tips for DeWalt DWS779 and DWS780

Both models are workhorses, but each has small quirks that affect how they slide. Knowing them helps you fix rough movement faster.

Out-of-Box Rough Slide

My DWS780 was stiff right out of the box. The head dragged like it was full of sand. These saws use bearings on one rail and bushings on the other, and they need a short break-in period.

If yours feels stiff, don’t force it. Just slide the head gently forward and back without pushing down. After a few dozen passes, it should smooth out. A light coat of dry PTFE spray helps too.

Head Flex at Full Extension

Every DWS780 owner notices a small flex when the saw is fully extended. Mine moves about 1/8 inch side to side if I push the handle. That’s normal — the rails are long and light to keep the saw easy to carry.

You can’t remove the flex fully, but you can limit it. Keep the blade sharp, feed lightly, and take shallow passes instead of deep ones. That reduces twist and gives cleaner cuts.

In real use, it won’t affect framing cuts, but for trim work, a gentle touch makes all the difference.

Dust Tube or Guard Rubbing

On one of my older saws, the dust chute rubbed the frame each time I pulled the head forward. It felt like a bearing issue, but it was just plastic-on-metal contact.

I fixed it by gently heating the plastic tube with a heat gun and reshaping it so it cleared the frame. You can do this with a hair dryer too — just go slow.

Always check for small interferences like this before assuming something major is broken. Many “grinding” issues are just parts rubbing in the wrong spot.

Safety and Maintenance Habits That Prevent Problems

Most sliding issues come from neglect, not defects. Regular cleaning and smart habits keep your DeWalt running smooth for years — even in rough shop conditions.

Monthly Maintenance

I treat my saw like my truck — routine care keeps it strong. Once a month, I:

- Clean and relube the rails with dry PTFE spray

- Check fence and bevel alignment with a square

- Inspect the power cord or battery terminals for debris

It takes about 15 minutes and prevents most slide issues before they start.

Shop Environment Matters

Where you live changes how your saw behaves. Here’s what I’ve learned across states:

- Humid areas (Florida, Texas): wipe the rails daily — sawdust turns sticky fast.

- Cold Midwest winters: metal shrinks, grease hardens — let the saw warm up before cutting.

- Dry Southwest: fine dust coats everything — reapply PTFE spray often to keep a slick film.

Adjusting your routine to your local climate keeps the slide smooth year-round.

Storage and Transport Tips

I used to leave my saw in the truck overnight — big mistake. Moisture and vibration are its worst enemies.

Now, I always:

- Lock the rail knob before transport so the head can’t slam

- Store it indoors or under cover

- Use a soft cover to keep dust out of the rails

A little care goes a long way. A clean, covered saw stays smoother, safer, and more accurate when you need it most.

When to Seek Professional Repair

I fix almost everything myself, but sometimes a DeWalt miter saw that won’t slide smoothly needs more than home repair. After years of working with these saws, I’ve learned when it’s time to call a pro.

If your saw still jams after cleaning, adjusting, and lubing — the problem runs deeper. Bent rails or stuck bearings can’t be fixed with a quick spray or tap. That’s when you need a qualified service tech.

Signs You Need a Service Center

Here’s how to know it’s time for expert help:

- The slide locks up even after cleaning and unlocking every part.

- You still hear grinding or squealing after adding dry lube.

- Rails look bent or scratched. Once warped, accuracy is gone.

- The carriage wobbles even after you tighten the screw — a sign of bad bearings.

I once tried to straighten a bent rail with clamps. Big mistake. It threw the blade out of square and made it worse. Some jobs need the right tools and gauges that home shops don’t have.

If your saw still feels unsafe or off-track, let a pro handle it.

Where to Get Help

When I need parts or repairs, I go straight to DeWalt Service Centers through toolservicenet.com. It’s the official source, and they stock parts for nearly every model — even older ones.

No service center nearby? Try Home Depot Tool Repair or Ace Hardware. They can fix common issues and check calibration.

Before you go, write down your saw’s model and Type number from the nameplate. It saves time and ensures you get the right parts.

Professional repair isn’t giving up — it’s smart maintenance. Once fixed, a good DeWalt can last another decade of hard work.

FAQs — Dewalt Miter Saw Not Sliding

Why won’t my DeWalt miter saw slide?

Usually, the lock knob is still on, or the rails are full of dust. Unlock the knob and clean the slides with a dry PTFE spray. Most stuck slides are fixed in five minutes.

Can I use WD-40 on my slide rails?

Only to clean. WD-40 removes grime, but it leaves oil that attracts dust. Wipe it dry and finish with a PTFE or Teflon dry lube.

What lubricant should I use?

Use a dry PTFE spray like WD-40 Specialist Dry Lube, Blaster Dry Lube, or CRC Dry PTFE. They keep slides smooth without collecting sawdust.

How often should I clean the slide?

Every 2–4 weeks if you cut often. Monthly is fine for light use. In humid places like Florida or Texas, wipe the rails after long sessions to stop rust.

Final Take — Keep Your DeWalt Sliding Smooth

A sticky DeWalt miter saw isn’t broken — it just needs care. Most problems come from dust, old grease, or a forgotten lock. Once you unlock, clean, and dry-lube it, your saw will glide like new.

I’ve used these saws in all kinds of weather — hot Florida garages and cold Midwest barns. A little care makes a big difference. The smoother your slide, the cleaner your cut.

Here’s the bottom line: smooth equals accurate. Keep the rails clean, use dry lube, and check alignment often. Treat your saw right, and it’ll stay sharp, safe, and ready for years to come.