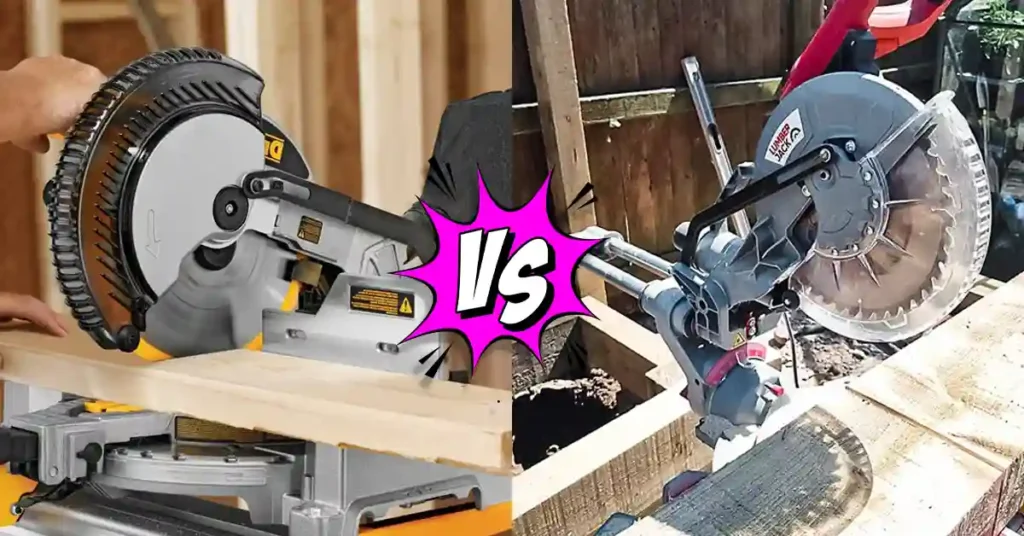

If you’ve ever stared at a row of miter saws wondering whether to pick a single or double bevel, you’re not alone. I’ve been there too—boots dusty, tape around my neck, trying to decide which saw would make my cuts cleaner and my work faster.

After years of projects—from a hot Florida garage to a cold Midwest shop—I’ve learned one thing: the choice isn’t just about price or fancy features. It’s about how the saw handles real work in real conditions.

This guide isn’t here to sell you a brand. It’s here to show what actually matters when you’re cutting trim on a dry Arizona job site, installing crown molding in a Colorado basement, or dialing in angles in your home shop.

No matter who you are—a weekend DIYer or a full-time contractor—understanding the single vs double bevel miter saw difference will save you time, effort, and a few headaches.

Table of Contents

Basic Function of Each Tool

What a Single Bevel Miter Saw Does

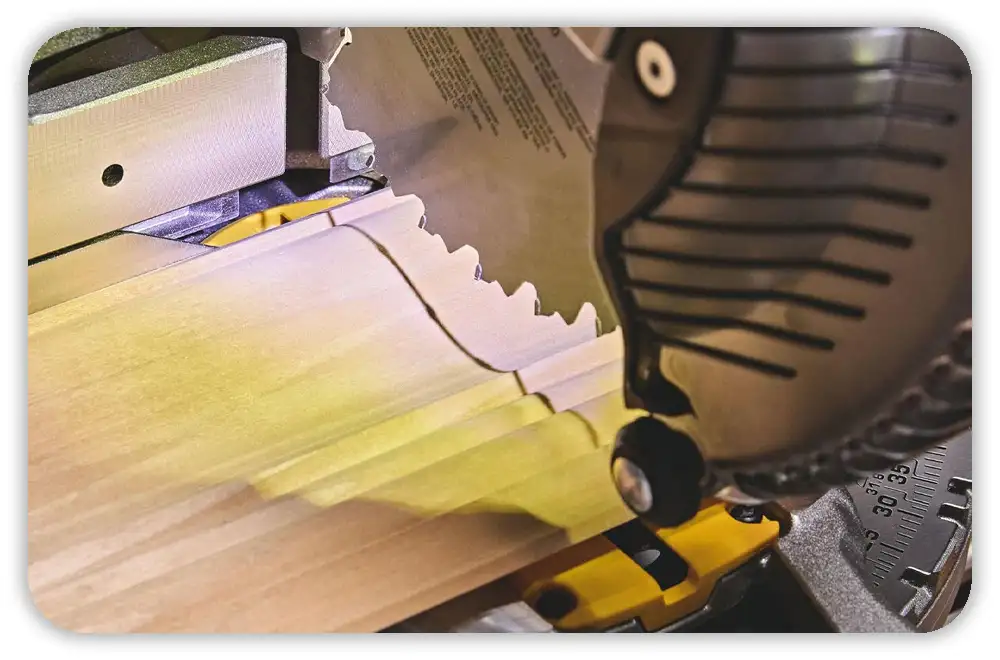

A single bevel miter saw tilts one way—usually to the left. That tilt lets you make bevel cuts, or angled cuts through the board’s thickness. When I first started building decks and framing walls, this was the saw I used most. It’s simple, steady, and great for everyday jobs.

You’ll see it used for baseboards, door casings, flooring, and framing. If your shop is small or you move tools often, this saw makes life easy. It’s light and takes up less space—handy when you’re working between a bench and a parked car.

The trade-off is time. When you need matching bevels on both ends of a board—like molding returns—you have to flip the piece. It’s not hard, but it takes care and patience to keep the angles right.

What a Double Bevel Miter Saw Does

A double bevel miter saw tilts both left and right. That means you can make matching bevel cuts without flipping your work. When I began doing finish carpentry—especially crown molding and cabinets—this feature saved me hours.

You just tilt the head to the other side, make your next cut, and keep going. No re-measuring, no flipping heavy boards, and no guessing which side you’re cutting. It’s faster, smoother, and more precise for repeat cuts.

This saw shines in trim shops, cabinetry, and high-volume renovation. It’s heavier and costs more, but the flexibility pays off. Pros and serious hobbyists love it because it cuts down on errors and speeds up production.

Technical & Practical Differences

After testing both saws—from framing in cold Chicago winters to trimming homes in humid Florida—I’ve noticed a few key differences that matter every day.

Performance & Precision

A double bevel saw keeps your board still on both sides of the cut, giving cleaner joints and better consistency. With a single bevel saw, accuracy depends more on how you flip and align the board. Both can be precise if tuned right, but the double bevel wins for mirrored or compound cuts.

Cutting Capacity & Power

Both saw types use 10- or 12-inch blades and often run 15-amp motors. But double bevel saws tend to have more torque and depth, built for pro work. That extra strength helps when cutting thick hardwood or dense trim.

Portability

Here, the single bevel saw wins. It’s light, compact, and easy to carry from the truck to the site. When I worked in tight Chicago condos, portability mattered more than features. In big home builds, the heavier double bevel saw felt right at home.

Ease of Setup & Maintenance

Single bevel saws are simpler to set up and maintain. Fewer moving parts mean fewer problems. Double bevel saws need more adjustment and care. I check my bevel calibration often—especially after moving the saw.

Safety

Both saws are safe when used correctly. Keep guards in place, secure your stock, and wear eye protection. Double bevel saws move more, so you need to stay aware when tilting. A solid stand and clean workspace help prevent slips or kickback.

Learning Curve

A beginner can learn a single bevel saw in one afternoon. The controls are easy, and most home projects don’t need complex angles. A double bevel saw takes more time to master. You’ll need to understand angles and tilt directions—but once you do, it’s second nature.

Comparison Table

| Feature / Factor | Single Bevel Miter Saw | Double Bevel Miter Saw |

| Accuracy | Good for standard angled cuts | Better for mirrored or compound cuts |

| Power Source | Usually corded; lighter motor | Often corded; higher torque motor |

| Portability | Light and easy to carry | Heavier and more stationary |

| Safety | Fewer moving parts | More adjustments to handle safely |

| Ideal Use | Trim, baseboards, framing | Crown molding, cabinetry, fine trim work |

When to Use Each

When a Single Bevel Works Best

If you work in small spaces or move often, go with a single bevel saw. It’s perfect for quick trim, flooring cuts, and light framing. I like using mine when working solo—it’s fast to set up and easy to carry.

In humid places like Florida, where wood can swell, I use it for quick on-site fixes. It’s reliable and simple when you don’t have time to overthink every cut.

When a Double Bevel Shines

If you’re into detailed work—trim, cabinets, or molding—choose a double bevel saw. It saves time and keeps your cuts consistent. When I was trimming homes in Arizona’s dry air, the double bevel made perfect mirrored cuts without flipping long boards.

It’s also great for shop setups where the saw stays put. The extra weight cuts vibration and improves accuracy for long runs of trim or complex angles.

Safety and Skill Level

Skill Required: Which Saw Is More Beginner-Friendly

If you’re new to power tools, start with a single bevel miter saw. It’s easier to handle, lighter, and less scary to learn on. I still remember my first time using one—I spent most of the day learning how to keep my fingers clear of the blade and my angles straight. Once I got the rhythm, it felt natural.

A double bevel miter saw takes more patience. You need to know your angles, tilts, and how both sides work together. It’s not hard once you practice, but it’s easy to get mixed up and cut the wrong side of a board. I’ve made that mistake more than once.

Best Practices

No matter which saw you use, safety always comes first. I’ve seen too many near misses caused by rushing or skipping gear. These are the habits I follow every time I cut:

- Eye protection: Always wear safety glasses. Even tiny chips can fly faster than you think.

- Gloves: Use thin, grippy gloves—not thick ones—so you can hold trim pieces safely.

- Dust mask or respirator: Use one when cutting MDF or treated lumber. Fine dust builds up fast indoors.

- Hearing protection: Miter saws often hit 100 decibels. Save your hearing for the long run.

- Work stability: Keep your board flat and supported on both sides. A wobbly piece can cause kickback or uneven cuts.

Seasonal Safety

Working across the U.S. taught me that safety changes with the season. In cold winters, thick gloves make it hard to grip boards, so I use thin, insulated ones and warm the saw before use. In humid southern states, moisture can make handles slippery and sawdust sticky, so I wipe down the tool before each job.

In dry, dusty areas like Arizona, fine dust builds up fast. I pause often to blow the saw clean, keeping visibility sharp and cuts accurate.

Maintenance and Durability

Cleaning and Storage

Keeping your saw clean is half the battle for long life. After every few jobs, I wipe down the base, fence, and blade guard. In humid states like Florida, rust appears fast—so I keep a small can of lubricant handy for metal parts. In dry climates, dust is the bigger enemy, so I focus on cleaning vents and the motor area.

For storage, I never leave the saw on a damp floor or in a truck overnight. A dry, covered space like a garage shelf or bench keeps rust and corrosion away.

Blade Care and Torque Checks

A dull blade doesn’t just cut slow—it’s unsafe. I check my blade before every project for pitch buildup or dull spots. A quick wipe with blade cleaner or mineral spirits restores shine. Once in a while, I send it out for sharpening instead of buying new.

I also check the blade bolt torque and fence alignment monthly. Even a small shift can throw off every cut.

Cord, Battery, and Switch Care

For corded saws, inspect cords often. Look for cuts, splits, or soft spots. For cordless models, avoid extreme heat or cold. I store batteries indoors year-round, even when the saw stays in the truck. Extreme temps drain battery life fast.

Longevity: Simplicity vs. Complexity

From my experience, single bevel saws last longer with less upkeep. They have fewer moving parts, so less can go wrong. Double bevel saws, while more flexible, need more regular checks because of their dual-axis tilt. But if maintained well, both can last a decade or more.

Summary / Conclusion

After years of switching between both, I’ve learned that single and double bevel miter saws each serve a purpose. A single bevel saw is light, quick, and easy to master—perfect for small jobs or mobile work. A double bevel saw offers speed and accuracy, especially for trim or cabinetry where mirrored cuts matter.

If you’re in the U.S., your environment also matters. In humid states, simple tools that clean up fast are a big plus. In dry climates, accuracy and dust control become key.

The real trick isn’t picking the “better” saw—it’s choosing the right one for your workflow. Whether you’re framing, trimming, or building furniture, knowing your setup makes all the difference.

FAQ: Single vs Double Bevel Miter Saw

Which is easier for beginners — single or double bevel?

A single bevel miter saw is easier to start with. It’s lighter, simpler, and helps you focus on the basics before moving to mirrored bevels.

Do pros use both types on job sites?

Yes. Many pros use a single bevel saw for mobile framing or quick repairs, and a double bevel saw for trim or cabinet work. It’s common to see both on the same site.

Does a double bevel cut faster?

Yes—especially on mirrored or repeat cuts. You save time by not flipping boards or re-measuring angles. Over big projects, that adds up.

How do I keep my miter saw accurate over time?

Clean it often, check calibration monthly, and store it in a dry, stable place. A quick check before each project keeps your cuts true.