It was a cold Saturday morning. I stood in my driveway. I finally knew why I needed better tools. I was trying to change a tire on my truck. One lug nut would not move.

I jumped on the tire iron. My knuckles were scraped. I was freezing. That struggle is exactly how an impact wrench works to save your day. It is not just a stronger drill.

It is a machine made for violence. It creates huge force. But it does not twist your arm off. Pull the trigger. You hear a sound. We call it the “ugga dugga.”

That noise is physics working for you. Let’s look inside the case. We will see what happens.

Table of Contents

The Core Mechanism

This is not just a spinning motor. It is a violent crash inside the metal case.

The Motor and the Spring

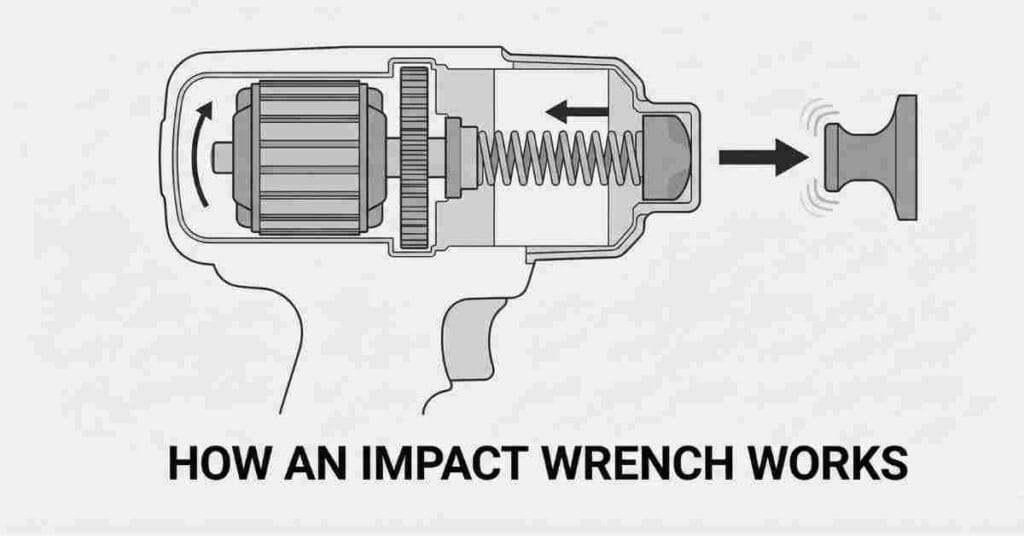

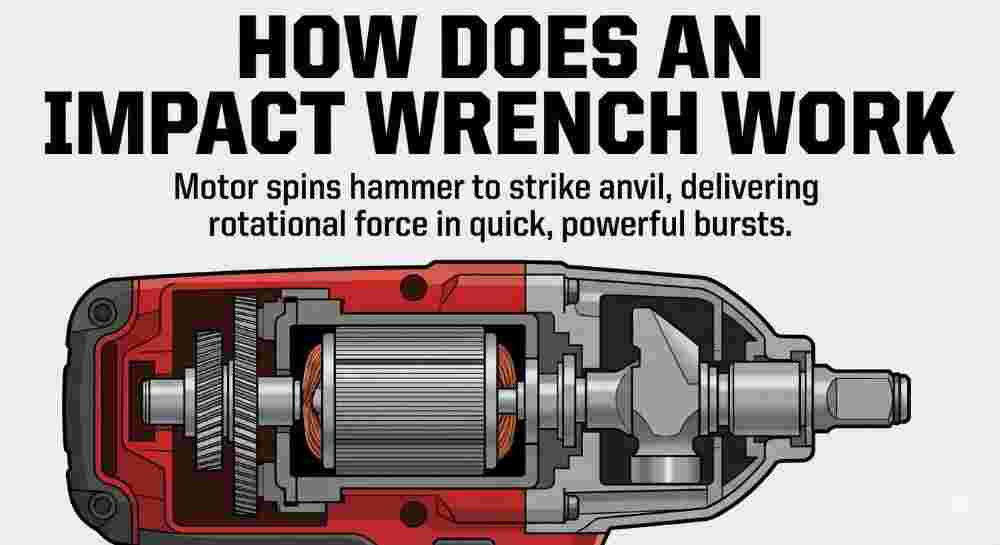

Most people think the motor drives the socket. That is not true. If it did, the tool would twist your hand. This happens when the bolt gets stuck. Instead, the motor drives a heavy cage.

I took apart my first wrench to grease it. I saw a large spring inside. I was surprised. When the tool hits a hard stop, the motor keeps spinning. But the output shaft stops.

This action squeezes that heavy spring. It builds up energy. It is like pulling back a rubber band. You can hear the motor whine change. This happens right before the magic.

The Hammer Strike

The spring is fully squeezed. Then it snaps back. It forces a heavy metal block to hit the output shaft. The block is the “hammer.” The shaft is the “anvil.” This is the core of how an impact wrench works.

Think of a stuck jar of pickles. You do not just twist harder. You slap the lid with your palm. That sudden shock breaks the seal.

The wrench does this 50 times a second. It slams the anvil over and over. This creates “breakaway torque.” It shatters the rust holding your bolt.

Why It Doesn’t Hurt Your Wrist

The best part is that you do not feel the twist. Have you used a large drill? If it binds up, it can hurt your wrist. That is constant torque.

The impact wrench is different. It gives force in short bursts. The energy goes into the bolt. It does not go into your hand. I can hold my heavy wrench with one hand.

It removes a rusted axle nut easily. It feels like a vibration. It does not feel like a twist. You can work longer. You do not get tired. It changes the game for garage work.

Power Sources: Air vs. Battery

You might be in a pro shop. You might be in a snowy driveway. The power source changes how the tool feels.

Pneumatic (Air) Impact Wrenches

For years, air tools were king. I grew up with them. I heard the hiss of air compressors in my uncle’s garage. Air wrenches are simple. They are light. They last a long time.

They use air to spin a rotor. The rotor drives the hammer. There is no heavy battery inside. They are easy to hold all day.

But the hose is a pain. I have tripped over air hoses many times. I have dragged them through oil. You are tied to the compressor. You cannot move far.

Cordless Electric (Battery) Impact Wrenches

This is where I spend my money now. Modern cordless wrenches changed everything. They use new lithium batteries. They use brushless motors. They are beasts.

Years ago, battery tools were weak. Today, my battery wrench is strong. It has more torque than my old air tools. I toss it in the trunk for trips. I carry it to the backyard. I fix the mower there.

The trade-off is weight. The battery makes the tool heavy. But I have freedom. I do not drag a hose. I will take the extra weight.

When to Use an Impact Wrench

You have a powerful hammer. That does not mean everything is a nail. Not every bolt needs huge power.

High Torque Uses

Use this tool when you need raw power. It is built for tough stuff. I live where they salt roads in winter. Rust is a constant battle.

I use my wrench for lug nuts. I use it for suspension parts. A bolt might be “frozen” by rust. A regular ratchet will not cut it. You might hurt yourself if you push too hard.

The wrench uses hammering action. It vibrates the rust loose. A twenty-minute struggle becomes a three-second zip. It is satisfying. You hear that bolt break free.

Stay Away from Small Bolts

But you must know when to stop. Never use an impact wrench on small bolts. Is the bolt head smaller than 10mm? Keep the big gun away.

The tool has too much power. It breaks delicate threads. You can cross-thread a bolt. You can snap the head off. Once that happens, your day gets worse.

I also avoid it for final tightening. You can over-tighten lug nuts. This warps your brake rotors. Always finish the job by hand. Use a torque wrench.

My Personal “Oops” Moment

I learned this the hard way last summer. I was replacing a mower blade. I was tired. I felt lazy. I grabbed the impact gun to tighten the bolt.

I did not thread it by hand first. I just pulled the trigger. The gun made its sound. Then—snap. The bolt head sheared off.

I stood there. I stared at it. I felt foolish. It should have been a ten-minute job. It turned into two hours. I had to drill out a broken bolt. Don’t be like me.

Essential Features to Look For

Are you heading to the store? Are you browsing online? Look past the colors. Check these specs first.

Hog Ring vs. Detent Pin

Many people miss this detail. It is how the socket attaches. The “Hog Ring” is a friction ring.

I prefer the Hog Ring. I can pull sockets off fast. I do this by hand. Do you switch sockets often? This is what you want.

The “Detent Pin” uses a locking pin. It holds the socket tight. This is good for high places. You will not drop a socket. But it is annoying for garage work.

Variable Speed and Modes

Old wrenches were all or nothing. You pulled the trigger. It went full speed. Newer models are smart. They help you avoid mistakes.

Look for “Bolt Removal Mode.” Look for “Auto-Shutoff.” I loosen a nut. The tool senses it. It slows down instantly.

This stops the nut from spinning off. It does not fly across the floor. I used to hunt for lost nuts. I looked under my workbench for twenty minutes. Now I have this feature.

Read More: How to Use a Ratchet Wrench

Conclusion

You now know how an impact wrench works. It is not just physics. It saves your body from strain. It makes work safer.

It uses smart design instead of brute force. You do not need to be strong. You do not need to fight the bolt. You just need the right tool.

Check your car trunk. Do you rely on a rusty tire iron? Think about upgrading. Your future self will thank you.

FAQs- How Does an Impact Wrench Work

What is the difference between an impact driver and an impact wrench?

Drivers use hex bits for wood screws. Wrenches use square drives for heavy nuts. An impact wrench has much more torque. It is the best tool for rusty car bolts.

Can I use an impact wrench to tighten lug nuts?

You can use it, but be careful. It is easy to tighten them too much. This creates damage. Use a hand torque wrench at the end. It ensures your wheels are safe.

Do I need an air impact wrench or a battery one?

Air tools are light but need a hose. Battery tools are heavy but free to move. Modern battery wrenches are very strong. They are the best choice for home use.

Why does my impact wrench not remove the lug nut?

The nut may be rusted tight. Your tool might need more power. Spray oil on the bolt first. Let it sit for a bit. If it is still stuck, you need a stronger gun.

Does an impact wrench need special sockets?

Yes, you need impact sockets. Regular chrome sockets can break or shatter. Impact sockets are made of black steel. They flex a bit to handle the force safely.