It was a chilly Saturday morning in my garage, and I was finally ready to swap the blades on my riding mower. I reached for my trusty Craftsman torque wrench, but then I froze. I realized I hadn’t touched it since I worked on my truck’s lug nuts months ago.

If you have ever felt that “am I doing this right?” panic, you are not alone. Learning how to adjust a torque wrench is the difference between a job well done and a snapped bolt. Let’s walk through it together so you can feel that satisfying click with total confidence.

Table of Contents

The Parts You Need to Know

Before we turn any dials, we need to look at what we are holding in our hands.

Think of your wrench like a precise scale. Most of us use a “click-style” wrench where a spring inside does all the heavy lifting. You have the head for your sockets, the main barrel with numbers, and a handle that spins.

I usually start by wiping the old grease off the handle with a shop rag. It helps me get a better grip on the knurled metal. You want to feel every tiny notch as you move the dial.

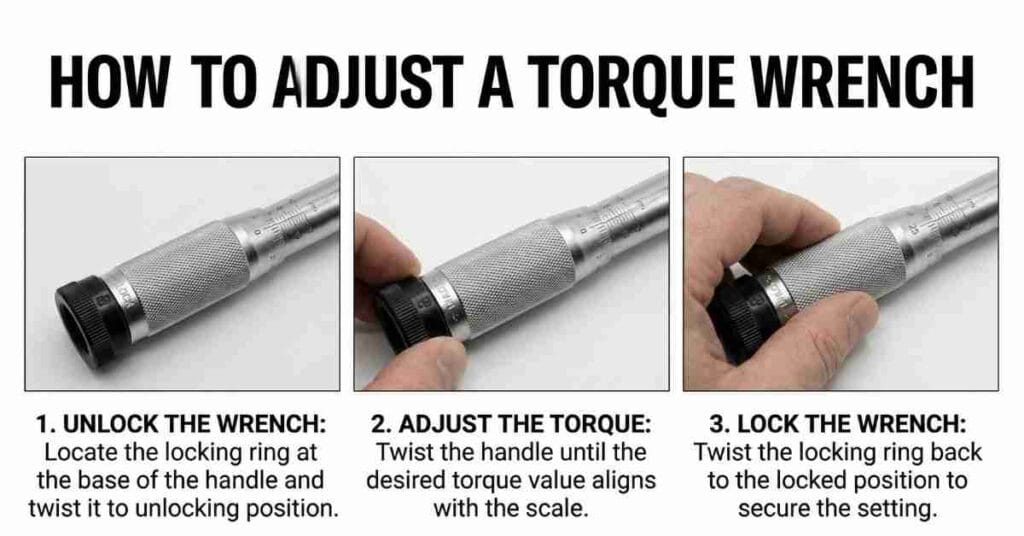

Step 1: Unlock the Grip

Most people forget this part and end up fighting the tool.

At the very bottom of your handle, there is a small knob or a ring you pull down. This is the lock. If it’s a DeWalt or Milwaukee model, it might feel a bit stiff if it hasn’t been used in a while.

Twist or pull it until the handle moves freely. I remember the first time I tried to force a locked wrench; I almost bruised my palm. Don’t be like me—just check the lock first.

Step 2: Set Your Base Number

Now we get to the actual math, but I promise to keep it simple.

Look at the vertical lines on the barrel of the wrench. These are your “big” numbers, usually in Foot-Pounds (ft-lb). Spin the handle until the top edge is right at the line below your target.

If I need 85 ft-lbs, I spin the handle until it hits the 80 mark. You will see the “0” on the handle line up with the center line on the tool. It’s a very clean, mechanical look that makes you feel like a pro.

Step 3: Dial in the Fine Details

This is where the magic happens and where we get that perfect precision.

The handle has smaller numbers around it, usually 0 through 9. Since we are at 80 and want 85, just turn the handle slowly to the right. Stop when the “5” aligns perfectly with that center line on the shaft.

I love the sound of the metal clicking softly as it turns. It’s a bit like opening a safe. Once you hit your number, stop right there and don’t let it drift.

Step 4: Lock It and Load It

You are almost there, but this next step is the most vital for your safety.

Push that locking ring back up or tighten the knob at the bottom. This keeps your setting from moving while you pull on the wrench. I’ve seen guys skip this and end up with uneven bolts because the dial shifted mid-job.

Give it a little shake to make sure it’s solid. Now you are ready to tighten those fasteners to ANSI or OSHA specs. It’s a great feeling knowing your wheels or blades won’t fly off down the road.

READ MORE: How Do You Use a Torque Wrench

Pro Tip: Don’t Store It Tight

This is the “secret sauce” that keeps your tool accurate for years.

When you finish your work, don’t just toss the wrench in your toolbox. Turn the handle back down to the lowest setting on the scale. If you leave it tight, the spring inside gets “tired” and loses its accuracy.

I used to leave mine cranked up until a buddy told me I was ruining my gear. Now, I treat it like a fine instrument. It takes ten seconds to unwind, and it saves you a lot of money on calibration later.

Why Accuracy Matters in the Cold

If you live in a place with big seasons, listen up.

Metal changes when it gets cold or hot. If your garage is freezing, let the wrench sit inside for a bit before you use it. I’ve noticed the “click” feels a bit different in the winter than in the heat of July.

A quick test “click” on a sturdy bolt can help you feel the tension. It’s all about building that muscle memory. Once you get the hang of it, you’ll never go back to “guessing” how tight a bolt is.

FAQs – How to Adjust a Torque Wrench

How do you adjust a torque wrench to the zero setting?

Unlock the handle first. Twist the grip until the zero line meets the center mark on the tool. Always store it at the lowest setting to keep the spring strong and accurate.

Can I use my torque wrench to loosen stuck bolts?

No, never do this. It can hurt the gears inside. Use a breaker bar for tough bolts instead. Save your torque wrench for precise tightening to stay safe on the job.

How often should I check my tool for accuracy?

Check it once a year or every five thousand clicks. This ensures your DeWalt or Craftsman tool stays precise. Regular checks help you avoid broken bolts or loose parts.

What should I do if I go past the click?

Stop right away. Loosen the bolt and try again. Going too far can stretch the metal or snap the head off. A single, smooth click is all you need for a perfect fit.

Why does my torque wrench click when I use it?

The click means you hit your goal. A small block inside trips once the right force is met. It is a smart way to tell you that the bolt is now safe and tight.