I still remember the frustration I felt when I started soldering. I bought a cheap iron from a local hardware store here in the US. It came with a sharp, pointy tip that looked precise.

I thought I was set up for success. But every time I tried to join two wires, the solder would ball up and roll off. I thought I just had bad hands. It turns out, I was just using the wrong tool for the job.

Selecting the right types of soldering tips changed everything for me. It wasn’t about skill; it was about physics. If you are struggling with cold joints, the tip shape is likely the culprit.

Let me walk you through the tips I use and why they might save your next project.

Table of Contents

The Chisel Tip (Type D) — My Daily Driver

If I could only keep one tip, this would be it. The chisel tip looks a bit like a flat-head screwdriver. It has a broad, flat face on two sides.

I use this for about 90% of my work. Whether I am fixing a guitar cable or working on a through-hole circuit board, this is my go-to.

The magic is in the surface area. That flat face touches more of the component leg and the pad at the same time. This transfers heat much faster than a point can.

For most US hobbyists working on standard electronics, a 2.4mm (3/32″) chisel is perfect. It makes the solder flow instantly, which saves your parts from overheating.

The Conical Tip (Type B) — The Beginner’s Trap

This is the tip that came with my first iron. It looks like a sharpened pencil. It seems like it would be great for precision work, right? That is exactly what I thought.

But here is the truth: it is terrible for heat transfer. Because the point is so small, very little heat gets to the joint. You end up holding the iron there too long.

I often see people burning traces because they are trying to force the solder to melt with this tip. Unless you are working in an incredibly tight spot, I suggest you put this one back in the drawer.

The Bevel or Hoof Tip (Type C) — The Drag Specialist

When I started getting into surface-mount (SMD) components, I was scared. The pins were so small. That is when I discovered the hoof tip.

It is shaped like a cylinder cut at an angle. It looks just like a horse’s hoof. The flat face can hold a small bead of liquid solder.

I use this for “drag soldering.” I simply drag the wet tip across a row of pins on a chip. It paints the solder onto the legs perfectly without sticking them together. It feels like magic the first time you do it.

The Knife Tip (Type K) — The Fixer

This one looks intimidating. It is shaped exactly like a knife blade. It has a sharp edge and a wide flat side.

I love this tip for cleaning up mistakes. If I accidentally bridge two pins together with too much solder, the sharp edge of the knife slices right through it.

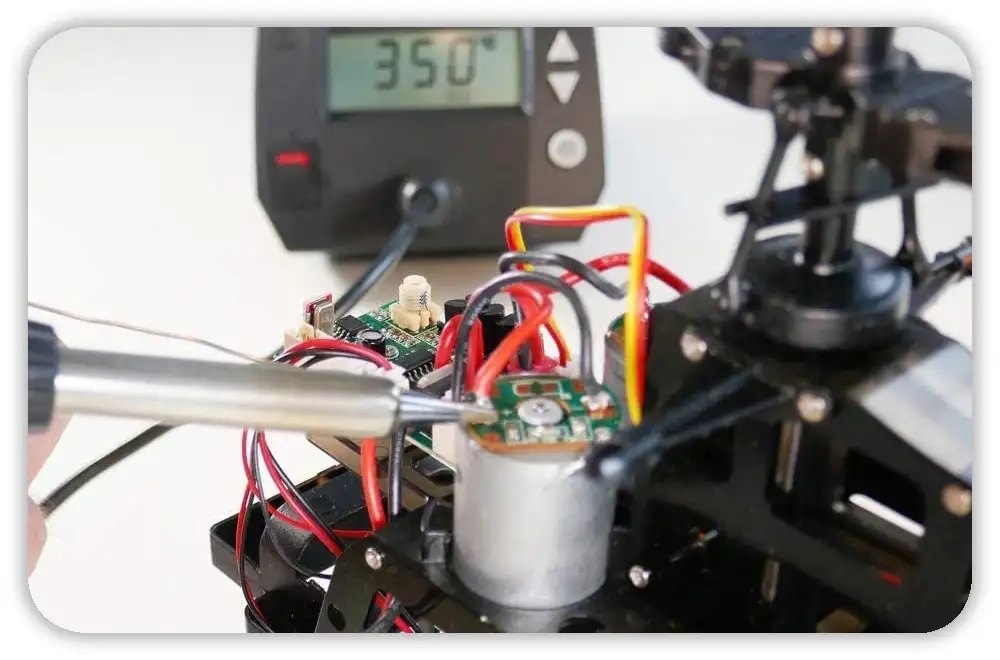

It is also great for heavy ground planes. I lay the flat side of the blade down, and it dumps a massive amount of heat quickly. It is a lifesaver when working on power supplies or drone parts.

Bent Conical (Type J) — The Reach

Sometimes, I just can’t get my hand in the right position. That is where the bent conical tip comes in. It is bent at a 30 to 45-degree angle near the end.

It mimics the angle of a dental pick. It lets me rest my hand comfortably on the bench while the tip reaches into a tight spot on the board.

I use this a lot when I am working under a microscope. It keeps my hand out of my line of sight so I can see what I am doing.

Needle or Micro (Type I) — For the Microscope

These tips are extremely fine, like a sewing needle. I only use these for microscopic work, like 0402 resistors that are barely visible to the naked eye.

Be careful with these. They cool down the second they touch anything. They don’t hold enough heat for standard wires.

If you try to solder a regular wire with this, the tip will stick to the wire and freeze. It is strictly for the tiniest, most delicate jobs.

A Final Note on Maintenance

No matter which tip you choose, you have to take care of it. I learned this the hard way after ruining my favorite chisel tip.

Never leave your tip clean and dry when it is hot. It will oxidize and turn black in minutes. Once it turns black, it won’t melt solder anymore.

I always melt a fresh blob of solder onto the tip before I turn off the station. That layer of solder protects the plating. It keeps your soldering tips shiny and ready for the next time you need them.

FAQs – Types of Soldering Tips

Which tip is best for a beginner?

The chisel tip is the best pick for new users. It holds heat well and makes joining wires easy. It is one of the top types of soldering tips to help you learn fast.

Why does my tip turn black and stop working?

Heat hurts the metal if the tip is dry. The black scum blocks the heat. Keep all types of soldering tips wet with tin to stop this and keep them working well.

Can I use a sharp point for every job?

No, a sharp point has poor heat flow. It cools down too fast on big parts. You need other types of soldering tips like a chisel to fix large joints and wires.

How do I clean my tip the right way?

Use a brass wool ball to wipe it clean. A wet sponge can shock the hot metal. Clean all types of soldering tips gently to help them last for a very long time.

What is the hoof tip shape used for?

A hoof tip holds a drop of tin on its face. It is great to drag across pins on chips. Most other types of soldering tips do not work as well for this fun task.