I remember my first time holding a soldering iron. It was a Saturday morning. I was trying to fix a broken guitar cable in my garage. I felt confident.

Ten minutes later, I had a burnt finger and a messy blob of metal. It wouldn’t stick. I was frustrated. I thought the tool was broken.

It wasn’t the tool. It was me. I didn’t know how heat worked. I treated solder like hot glue. That is the mistake most of us make.

Soldering is easy once you know the secret. It is about heat control, not melting wire. I want to save you that frustration. Let’s learn to do it right.

Table of Contents

What a Soldering Iron Actually Does

Most people think solder “sticks” like glue. It doesn’t. Glue sits on top of things. Solder is different. It fuses with the metal.

It creates a new metal alloy at the joint. If it doesn’t fuse, it falls off. We call this “wetting.” It flows like water when it is right.

Heat transfer, not melting solder

Here is the biggest secret. The iron tip does not melt the solder directly. The iron heats the part. Then, the part melts the solder.

If you touch solder to the iron tip, it melts instantly. But it won’t stick to the wire. The wire is too cold. The solder just beads up and rolls off.

You must deal with thermal mass. A thick wire needs more heat than a thin leg on a chip. You have to heat the work until it is hot enough to accept the solder.

Common myths beginners believe

I used to think “more heat fixes everything.” I would crank my dial to max. This just burns the board and ruins the tip.

Another myth is “shiny solder means a good joint.” This is mostly true, but lead-free solder can look dull. You have to know your materials.

Many think flux is optional. It isn’t. Flux cleans the metal so the solder can stick. Without flux, you are fighting a losing battle against invisible dirt.

Choosing the Right Soldering Iron for the Job

The iron you grab on a Saturday decides your mood. A bad iron fights you. A good iron helps you.

Wattage and temperature control basics

For small electronics, you need 25 to 40 watts. This is safe for circuit boards. It won’t cook the sensitive parts too fast.

For thick wires or connectors, you need power. I use 60 to 80 watts here. Heavy wires suck heat away fast. You need an iron that keeps up.

I prefer adjustable stations. Fixed temperature irons are okay for rough work. But a station lets you dial in exactly what you need.

Popular U.S. brands people actually use

You will see many cheap brands online. I steer clear of them. In the US, parts and tips for big brands are easier to find.

I started with a Weller. They are a classic workhorse. Hakko is another favorite of mine. Their blue and yellow stations are everywhere for a reason.

If you are in the garage, brands like Milwaukee or Ryobi make great cordless irons. They are perfect for fixing wires in a car.

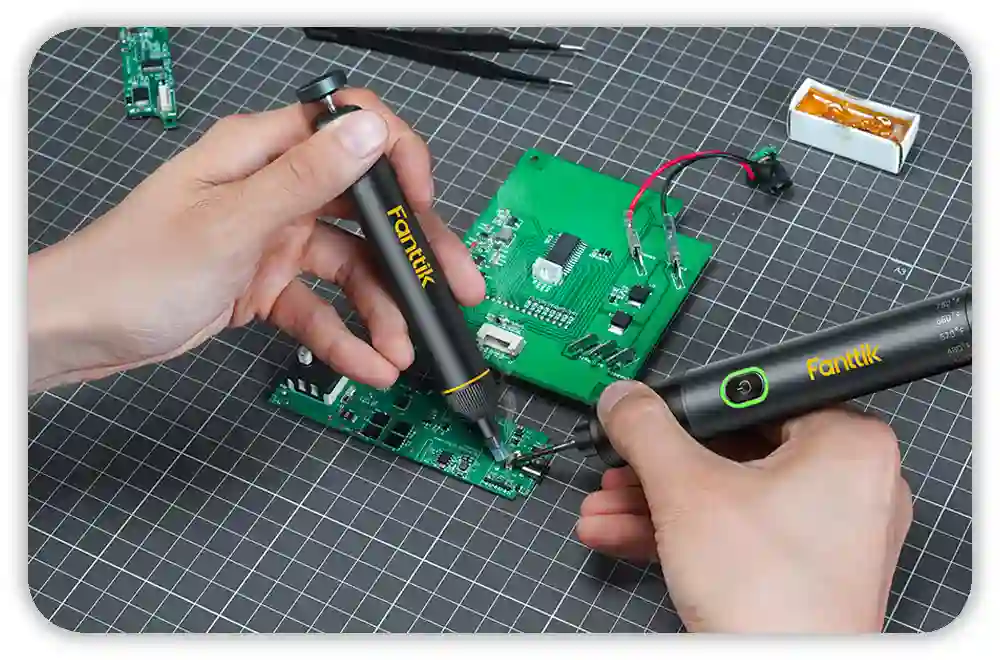

Tip shapes and when they matter

The tip shape changes how heat moves. Most irons come with a “conical” tip. It looks like a sharp pencil.

I hate conical tips. They don’t hold enough heat. The very point is too small. It cools down the second you touch it.

Get a chisel tip. It looks like a flat screwdriver. The flat face holds heat well. It transfers that heat to your wire fast. It solves most beginner problems.

Safety First

Soldering injuries are quiet. There are no sparks. There is no loud noise. You just smell burning skin, then you feel the pain.

Basic shop safety habits

Always wear ANSI safety glasses. Solder can “spit” hot flux. You do not want that in your eye. It happens faster than you can blink.

Ventilation is key. Rosin flux fumes can hurt your lungs. I open a window or use a small fan. It blows the smoke away from my face.

Use a real stand. Never lay the iron on the table. It will roll. It will burn your mat. Or worse, it will burn your arm.

OSHA-style common sense

Treat every iron like it is hot. Even if it is unplugged. You can’t see heat. Assume it will burn you.

Keep cords clear. I once tripped on a cord and pulled a hot iron off the bench. It was scary. Now I tape cords down or route them carefully.

Setting Up Your Workspace the Right Way

Most bad solder joints start before the iron even warms up. If you are cramped, you will make mistakes.

Bench setup that saves time

You need a stable surface. A wobbly table is a nightmare. You are working with hot liquid metal. You need steady hands.

Good lighting is vital. If you can’t see the joint, you can’t fix it. I use a bright LED desk lamp. I aim it right at my hands.

“Helping hands” are great. These are little clips that hold your wire. Real clamps work too. Never hold the wire with your fingers. It gets hot!

Materials you should have ready

Buy good solder. I use 60/40 leaded solder for practice. It melts easily and flows smooth. Lead-free solder is safer but harder to use.

Get a flux pen. Extra flux makes everything easier. It helps the solder flow into tight spots.

You need a tip cleaner. A wet sponge works, but it cools the tip too much. I use brass wool. It scrubs the tip clean without dropping the heat.

How to Use a Soldering Iron Step by Step

This is the part most guides rush. Don’t rush. This is where skill forms. Take your time here.

Step 1 – Heat the iron properly

Plug it in. Set it to about 650°F (350°C) for leaded solder. Wait a minute.

Don’t trust the dial instantly. Let the heat soak into the metal tip. It needs to stabilize.

Step 2 – Tin the tip

“Tinning” means coating the tip in fresh solder. Touch a little solder to the hot tip. It should shine like a mirror.

A shiny tip transfers heat. A dull, black tip blocks heat. I re-tin my tip every time I pick up the iron.

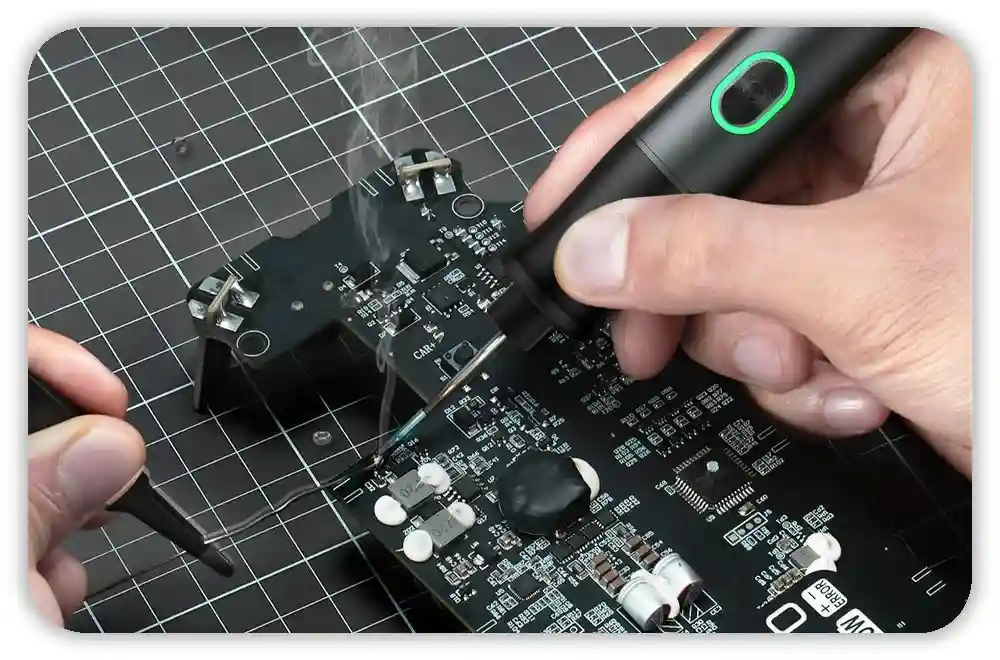

Step 3 – Heat the joint, not the solder

Place the iron tip against the two parts you want to join. For example, the wire and the metal pad.

Touch both parts at once. Count to two. You are heating the metal up. Do not add solder yet.

Step 4 – Feed solder and remove cleanly

Keep the iron in place. Touch the solder wire to the joint, not the iron. If the joint is hot, the solder will melt and flow.

Feed just enough to cover the connection. Then remove the solder wire. Finally, remove the iron.

Keep the part still. Let it cool for a second. If you move it, the joint will crack.

Common Beginner Mistakes (And How to Fix Them)

If solder beads up or turns dull, you didn’t “mess up.” You just missed a step. I have made all these mistakes.

Cold joints

A cold joint looks grainy or frosty. It might look like a blob sitting on top of the pad. It is not fused.

This happens when the part wasn’t hot enough. To fix it, add flux and reheat it. Wait for the solder to flow smoothly.

Burnt flux and overheated pads

If you hold the iron too long, things burn. You will see black goo. The board might turn brown.

You can clean burnt flux with alcohol. If you lift a pad off the board, that is harder to fix. Speed comes with practice.

Tip problems that ruin everything

If your tip turns black and won’t melt solder, it is oxidized. This happens if you leave the iron on high heat for too long.

Keep the tip tinned. Always leave a blob of solder on the tip when you turn it off. This protects the coating from air.

Practicing Before You Touch the Real Project

Every experienced tech practiced on scrap first. No exceptions. I ruined many cheap parts before I touched my expensive gear.

Best practice materials

Find an old broken radio or toy. Take it apart. Practice removing parts and putting them back.

Buy a cheap “prototyping board.” Buy a bag of cheap resistors. Solder them in rows. It is cheap and stress-free.

What to look for as you improve

Look for the shape. A good joint looks like a small volcano. It should be concave, not a ball.

It should be shiny. It should cover the whole pad. As you get better, you will work faster. You won’t need to think about it.

When to Stop and Let the Joint Cool

Patience is a soldering skill. Moving too fast ruins good work.

Cooling time basics

Do not blow on the joint. I know it is tempting. But cooling it too fast makes the metal brittle.

Let it cool naturally. It only takes a few seconds. Watch the shine turn slightly solid. That is when it is safe to move.

Final Thoughts

The first few joints always look rough. That is normal. My first board was ugly. But it worked.

Control comes fast once heat and timing click. You will feel the solder flow. It becomes satisfying.

You don’t need the most expensive station. You need practice. Focus on the technique. One clean joint feels better than ten rushed ones.

FAQs – How to Use a Soldering Iron

How do you use a soldering iron correctly for beginners?

To use a soldering iron, heat the metal parts first, then add solder to the joint. The solder should flow smoothly. Practice on scrap wire before fixing real electronics.

Why does solder not stick when using a soldering iron?

Solder will not stick if the metal is dirty or too cold. Clean the joint, add flux, and heat the parts longer. The solder should melt from the joint, not the tip.

What temperature should a soldering iron be set to?

For leaded solder, set the iron near 650°F (350°C). Lead-free solder needs more heat. Too much heat burns parts, so steady temperature matters more than max power.

Which soldering iron tip is best for beginners?

A small chisel tip works best for beginners. It holds heat well and transfers it evenly. Conical tips cool fast and make learning harder than it needs to be.

Is flux really necessary when using a soldering iron?

Yes, flux is important when learning how to use a soldering iron. It cleans the metal and helps solder flow. Without flux, joints often turn dull or weak.