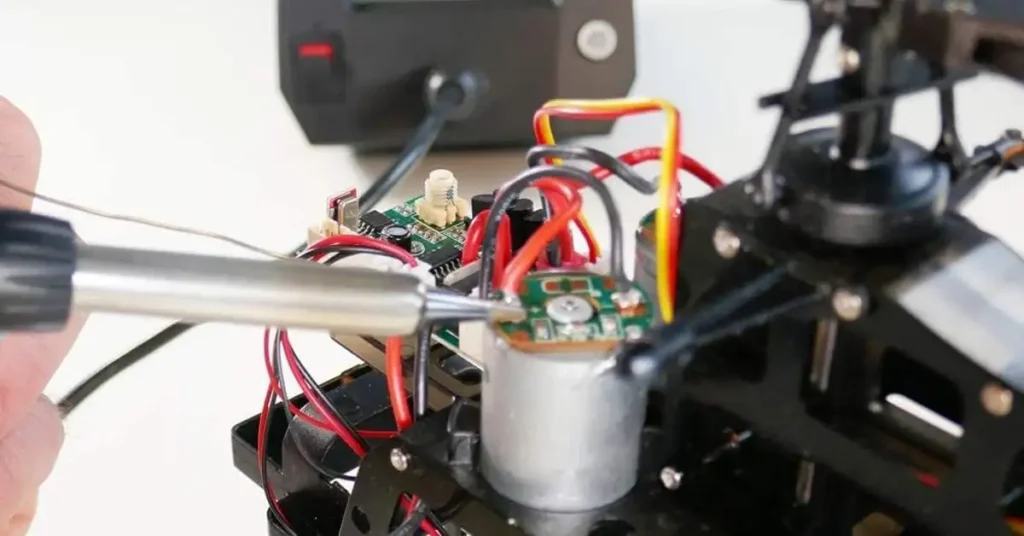

I remember the first time I sat down to fix a broken guitar cable. I had my soldering iron ready and felt pretty confident. But ten minutes later, I was just angry.

The tip of my iron wasn’t shiny silver anymore. It was coated in a dark, crusty layer. When I tried to melt fresh wire, it just rolled off like water on a duck’s back. I kept asking myself, “Why is my solder turning black?”

If you are stuck in this same spot, don’t worry. I learned the hard way that this is a common issue for us hobbyists. It usually comes down to heat, air, and how we treat our tools. Here is what I found out.

Table of Contents

Mistake #1: I Turned the Heat Up Too High

When I first started, I thought hotter meant faster. I plugged my iron into the standard 110V outlet here in the workshop and dialed it to the max. That was a huge mistake.

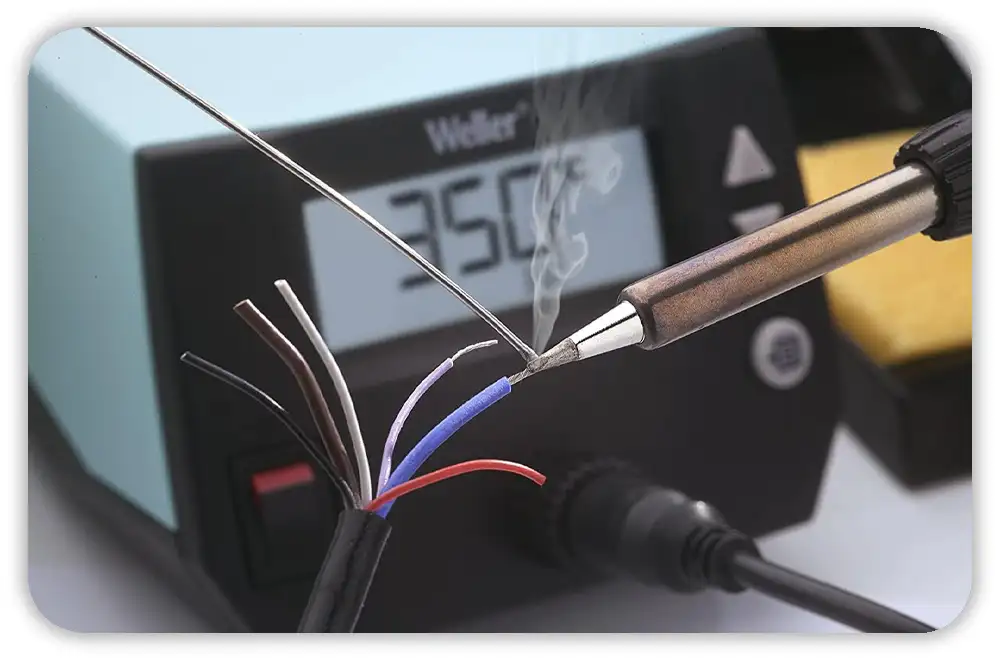

Most soldering jobs only need about 600°F to 700°F (around 350°C). I had mine set way over 800°F. At that temperature, oxidation happens almost instantly.

The metal can’t handle that much heat for long without protection. If you are using a basic stick iron without temperature control, it might be running too hot by default.

Mistake #2: The Wet Sponge Trap

For years, I used a wet sponge to clean my tip. I saw people do it online. It makes that satisfying “psshhh” sound. But I realized this was actually hurting my gear.

The thermal shock from the cold water causes micro-cracks in the plating. Plus, water contains oxygen, which feeds the rust.

I switched to a brass wire cleaner. It looks like a golden scouring pad. It scrapes off the crud without cooling down the tip. It changed everything for me.

The “Black Goo” on the Joint

Sometimes, it wasn’t just the tip. I noticed black sticky stuff around the wire I was soldering. This is different from the tip turning black. This is usually burnt flux.

Flux is the cleaner inside the solder wire. If you heat it for too long, it burns into a hard carbon residue. It looks messy, but it’s usually just cosmetic.

However, here in the US, many of us are switching to lead-free solder to be safer. I noticed lead-free stuff needs higher heat, which leads to more burning if you aren’t careful.

How I Finally Fixed It

So, how did I get my shiny silver tip back? I bought a little jar of “Tip Tinner.” It’s a mix of strong cleaner and solder powder.

I dipped my hot, black tip into it. It sizzled, and when I pulled it out, it was bright silver again. It felt like magic.

Now, I follow a strict rule. I never put my iron away “dry.” Before I turn it off, I melt a big blob of solder onto the tip and leave it there.

My New Routine

That blob acts like a seal. It keeps the air away from the iron while it cools down. The next time I turn it on, I just wipe that old blob off, and the tip is fresh underneath.

Learning why is my solder turning black saved me a lot of money on replacement tips. It just takes a little care and lower heat.

FAQs – Why Is My Solder Turning Black

Why is my soldering iron tip turning black?

The hot metal reacts with the air in the room. This causes rust, also known as oxidation. It forms a hard dark crust. This crust blocks the heat from melting your wire.

How do I fix a black soldering tip?

Rub the hot tip on a brass wire sponge first. If that does not work, use a tip tinner paste. This cleans the dark rust off quickly. The tip will shine silver again.

Is the black stuff on my solder joint bad?

That dark spot is likely just burnt flux. It happens if the iron is too hot or stays on the wire too long. It is safe, but you can clean it off with a brush and alcohol.

Can I use sandpaper to clean my iron tip?

No, do not use a file or sandpaper. This ruins the outer metal layer. Once that layer is gone, the tip will not work. Only use soft brass wool or a wet sponge.

How do I stop my iron from turning black?

Turn the heat down to a lower setting. Never leave the iron on when you are not using it. Always add a blob of solder to the tip before you turn it off to seal it.