The first time this happened to me, I thought my tool had lost its mind. My soldering iron felt hot, but the solder would not melt or stick. It was one of those slow mornings when I wanted to fix a simple joint. Instead, I sat there in mild panic while the metal refused to move.

If you have faced a soldering iron heating but not soldering, you know the strange mix of doubt and frustration. It is common for beginners, but I learned that even people with experience fall into this trap. Today, I want to share what caused it in my case and how I made sense of it step by step.

How Soldering Is Supposed to Work

I like to keep things simple. Good soldering depends on clean metal, steady heat, and a bit of flux. The iron warms the joint, the flux cleans the surface, and the solder melts and flows. When this chain breaks, nothing works the way you expect.

I did not understand this at first. I thought heat alone was enough. But I learned that heat has to move into the parts, not just sit at the tip.

Common Reasons for Soldering Iron Heating but Not Soldering

Many things can cause a soldering iron to heat up but not solder. Most issues come from weak heat transfer, surface problems, or the wrong temperature.

Tip Not Transferring Enough Heat

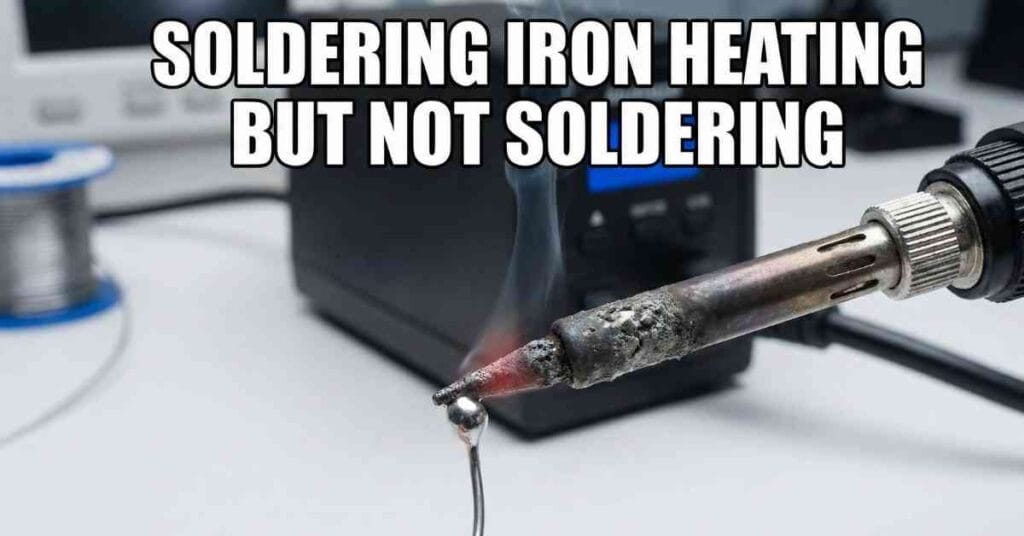

One day I looked at my iron tip and noticed a dull film on it. It was a thin layer of oxide. It stopped the heat from moving into the joint. The tip felt hot in my hand, but the joint stayed cold. I wiped it clean, added fresh solder, and the change was instant.

I have seen this happen with cheap tips sold in basic USA kits. Many of them oxidize fast, so a quick clean helps more than you think.

Insufficient Temperature for the Solder Type

I once grabbed a roll of lead-free solder without looking at the label. It needs more heat than leaded solder. I held the iron to the wire, but the solder sat still. I thought my iron had failed, but it was just the wrong temp.

Lead-free solder is common in stores across the USA due to safety rules, so check the melting point before you use it.

Thermal Mass of the Workpiece Too Large

I still laugh at how long I held the iron to a thick wire one afternoon. The wire pulled all the heat away like a small radiator. The solder never melted. It took me a while to realize the wire needed more heat than the iron could send.

Thick wires, copper pads, and metal shells act like heat sinks. They make the soldering iron look weak even when it is fine.

Flux Problems

There was a day when I forgot to add flux, and the solder rolled off the joint like a tiny metal bead. The metal was not clean, and the solder refused to bond. The joint looked dull and dry.

Once I brushed in a little flux, the metal warmed and took the solder with ease. Many USA solder kits come with flux built in, but I still keep a small jar nearby.

Iron Heating Element Issues

I also had a soldering iron that felt warm but never reached real working heat. The handle tricked me into thinking it was ready. But the tip stayed cool. Later I found out the heating element inside had worn out.

If your iron heats up but still fails, the issue may be inside the tool. No amount of cleaning or flux changes that.

Troubleshooting Steps (Practical Guide)

Here is the simple flow I follow when my soldering iron is heating but not soldering.

First, I test the solder at the tip to see if it melts. Then I clean the tip and add fresh solder so the heat moves well. After that, I check the temperature setting and the type of solder I am using. I also add a bit of flux if the joint looks dull or greasy.

When all else fails, I try a different solder or look at the iron itself. If it still feels weak, the element may need help or a replacement.

Causes vs Symptoms vs Fixes

This table gives a quick way to match what you see with what you can do. It helped me spot issues fast when my soldering iron heated but refused to solder.

| Cause | Symptoms Noticed | How I Fixed It |

| Dirty or oxidized tip | Solder would not stick, tip looked dark | Cleaned, tinned, or replaced tip |

| Tip not hot enough | Solder melted only on the tip | Raised temp or checked iron wattage |

| Lead-free solder | Slow melt, dull look | Raised temp 30–50°C and added flux |

| Workpiece too thick | Joint stayed cold | Held iron longer or used higher watt iron |

| Poor or no flux | Solder refused to flow | Added fresh flux |

| Bad solder wire | Old or cheap solder acted strange | Switched to a better roll |

| Iron malfunction | Handle warm but tip weak | Replaced heating element or iron |

Real-World Examples

One time the solder melted on the tip but not on the copper pad. I felt confused until I learned it was a heat transfer issue. The pad stayed cold while the tip stayed warm.

Another day the solder would not melt on a thick wire no matter how long I waited. That was a thermal mass problem. The wire took more heat than the iron could give.

Preventative Tips

Now I tin the tip before each job. It takes a few seconds and saves a lot of stress. I also use decent solder, because the ultra-cheap rolls can act strange and slow.

Flux stays close to me on my desk. I pick irons with enough wattage, around 40W to 60W for most small jobs. And I replace worn tips before they cause trouble.

Conclusion

Most times, the issue is not a mystery. When my soldering iron heats but does not solder, it always comes down to heat transfer, clean metal, or the right temp. Once I check these things, the fix shows up fast.

Take your time, follow the signs, and the solution will come to you too. It did for me, and it made my workdays a lot smoother.

FAQs: Soldering Iron Heating but Not Soldering

Why is my soldering iron heating but not soldering?

Your tip may be dirty or too cool. Clean the tip and check the temp. This often fixes a soldering iron heating but not soldering.

Why won’t solder melt on the joint even when the iron is hot?

The joint may stay cold due to poor heat flow. Hold the tip on the joint longer so heat moves in and the solder can melt.

Can bad solder cause my soldering iron to heat but not solder?

Yes. Old or low-grade solder melts slow and may not stick. Fresh solder helps when a soldering iron heats but will not solder well.

Do I need more flux when my solder will not stick?

Often yes. Flux cleans the joint so the solder can bond. A small drop can help fast when the solder does not flow.

Could a weak heating element cause this problem?

Yes. The iron may feel warm but the tip stays cool. If this keeps happening, the element may be worn and need a check.