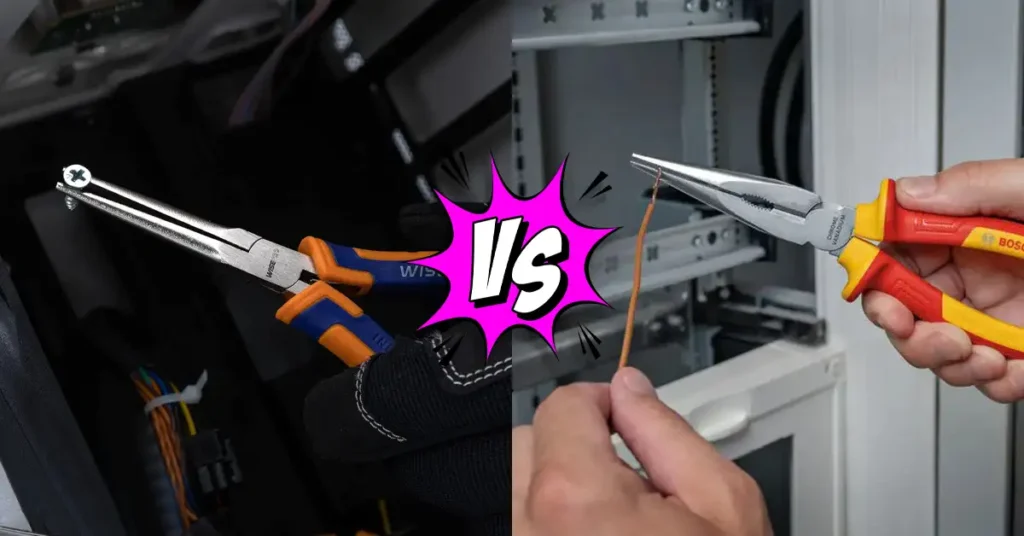

For years, I thought needle nose and long nose pliers were the same. They look almost identical in a toolbox. But after using both in real jobs, I found out they’re not. The difference shows up when you need control, reach, or power.

I’m not here to promote any brand. I just want to share what I’ve learned from using these tools in real U.S. garages — from cold Midwest basements to hot, humid Florida workshops.

Both tools are handy, but knowing when to grab which one can save time and prevent mistakes.

Here’s what I found after testing both side by side in real shop conditions.

Table of Contents

Basic Function of Each Tool

Before comparing them, let’s look at what each tool does. They look similar, but their design and feel tell you how they’re meant to be used.

Needle Nose Pliers

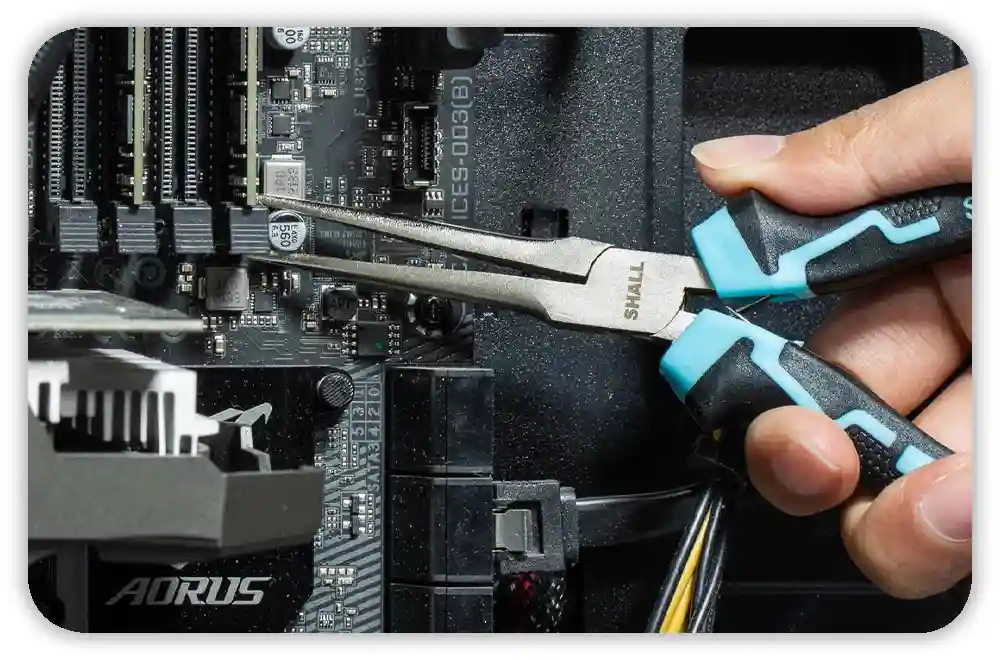

Needle nose pliers are made for small, precise work. Their jaws are slim and taper to a sharp point. That fine tip helps you grip tiny parts, bend wire, and cut in tight spots.

I use them for electrical work, craft repairs, and jewelry fixes. The light touch makes them perfect when you don’t want to crush or twist a small piece.

Long Nose Pliers

Long nose pliers have a longer, stronger jaw. They reach deeper and grip harder than needle nose types.

I use them when I need to grab a wire behind a dashboard or twist a part in a tight engine bay. They’re great for automotive jobs, HVAC work, and fishing gear setups.

That extra length gives you better reach and more leverage — especially in awkward spaces.

Technical & Practical Differences

After testing both, here’s what stood out:

- Precision: Needle nose pliers are best for small, detailed work.

- Reach: Long nose pliers reach deeper and hold stronger.

- Durability: Long nose pliers can handle more stress and weight.

- Portability: Needle nose pliers fit better in a tool belt or pocket.

- Ease of Use: Both are beginner-friendly. Needle nose feels easier for small repairs.

- Safety: A steady grip prevents slips. Long nose pliers give better control under pressure.

- Learning Curve: Needle nose pliers teach control and patience.

In humid Florida, I noticed rust builds fast, so a quick wipe helps. In the cold Midwest, hinges stiffen up — a drop of oil fixes that. Out West, dusty air means cleaning the joint more often.

I’ve used DeWalt, Milwaukee, and Craftsman tools. Each has its own handle feel and hinge strength, but the basics stay the same.

Comparison Table: Needle Nose vs Long Nose Pliers

| Feature / Factor | Needle Nose Pliers | Long Nose Pliers |

| Jaw Length | Shorter, fine-point tip for precision | Longer jaws for extended reach |

| Grip Strength | Best for delicate or light-duty tasks | Stronger grip for thicker wires |

| Precision | Excellent for electronics or detail work | Good for medium-detail jobs |

| Access | Ideal for tight or narrow spaces | Better for deeper, hard-to-reach areas |

| Durability | Great for light to moderate use | Built for tougher, frequent work |

| Portability | Compact and easy to carry | Slightly bulkier but still manageable |

| Ideal Use | Electrical, craft, or small repair tasks | Automotive, HVAC, or general maintenance |

When to Use Each

I grab needle nose pliers when I need accuracy — like bending a wire on a circuit board or fixing a tiny part.

For bigger jobs, like car wiring or tightening clips in deep spots, long nose pliers are my go-to. The extra reach saves time and keeps my hands out of cramped spaces.

In my experience across U.S. workshops, both are essential. From humid garages to cold basements, I use one or the other almost daily.

Safety and Skill Level

Both tools are easy to learn, but they still need care. A quick slip can pinch your hand or cut a wire.

Always wear safety glasses, especially when cutting wire. In cold or dusty places, gloves help with grip and comfort. Store them properly to prevent dull jaws or rusted hinges.

Good habits keep your hands safe and your tools sharp.

Maintenance and Durability

Keeping these pliers in shape takes only a few seconds:

- Clean: Wipe jaws and hinges after each use.

- Oil: Add a drop of light oil to keep them moving smoothly.

- Store: Keep them dry — a clean toolbox or hanging rack works best.

In damp areas, I use a small cloth and oil to stop rust. In colder regions, that also keeps the hinge from freezing up.

Summary / Conclusion

After using both tools for years, I’ve learned they each have a clear role.

- Needle nose pliers are for fine, detailed, and careful work.

- Long nose pliers are for reach, strength, and deep access.

If you do home repairs, electrical work, or DIY projects, you’ll use both often. Having each one ready saves time and makes every job smoother.

FAQs for Needle Nose vs Long Nose Pliers

What’s the difference between needle nose and long nose pliers?

Needle nose pliers have shorter, sharper jaws for fine work. Long nose pliers are longer and stronger for deep or tight spaces. Each fits a different job need.

Can I use long nose pliers instead of needle nose pliers?

Not always. Long nose pliers reach farther, but needle nose pliers give better control for small wires or delicate tasks where precision counts.

Are needle nose pliers good for electrical work?

Yes. Their narrow tips grip and bend small wires safely. Electricians use them to twist, cut, and place wires in tight spots without damage.

Which type of pliers lasts longer?

Both can last for years with care. Keep the jaws clean, oil the hinge, and store them dry to prevent rust, especially in humid or cold areas.

Do professionals use both needle nose and long nose pliers?

Yes. Most electricians, mechanics, and DIYers use both. Each plier offers a mix of reach, grip, and control that helps get precise work done right.