It was a dark and wet Tuesday afternoon right here at my house. I had to clean my big living room rug before friends came over. My large brown dog sheds thick fur all day long on the floor. Loose hair gets all over the house fast and makes a huge mess.

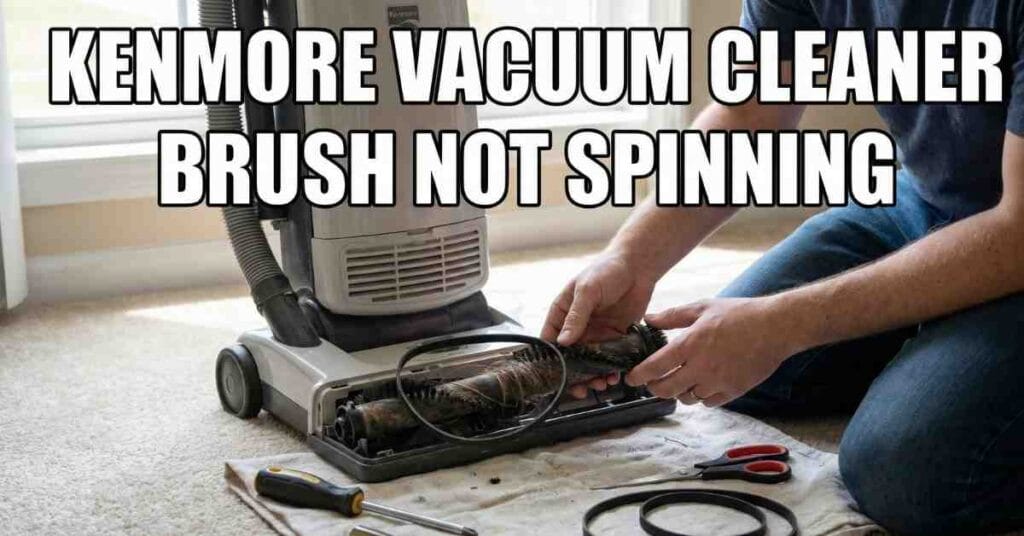

I plugged my Kenmore vacuum cord in the wall socket near the door. The main big motor turned on with a loud strong hum right away. The main suction felt strong and pulled the rug up a bit. But the bottom brush did not spin at all when I pushed it.

The wide head just pushed the dog hair in a pile on the rug. I felt mad and a bit sad that my chore was now much harder. I bent down and smelled the faint scent of hot burned rubber. I knew I had to fix the machine right then and there.

I have fixed lots of these home tools over a long time. I write a lot about how to fix tool bugs and clogs. Most of the time this brush issue is a quick and easy fix. You do not need to pay a pro high fees for this quick job.

Why the Brush Roll Stops Fast

Your big floor machine does two main jobs for you as you push it. It sucks the loose dirt deep inside the main dust bag or cup. It also sweeps the soft rug threads with a stiff bristle brush. The spinning part uses a round block of wood or hard plastic.

Some folks like to call this part an agitator when they talk about it. A tiny motor inside the head makes this round roll spin very fast. A flat rubber drive belt links the tiny motor to the big roll. When the roll stops it means a part broke or got stuck fast.

The main parts are quite easy to look at in your house. You just take them out one by one to see what is wrong. I like to use hard facts to find the main cause of the snag. I keep a log of what breaks the most on these floor machines.

Table of Common Brush Fixes

Here is a list of what I see go wrong the most often. This helps you know what part to check first when you start. It saves you time and keeps your head cool while you work.

| Broken Part Found | How Often It Fails | Time to Fix It | Tools You Use |

| Hair and long string | Happens a lot | Five full mins | Sharp scissors |

| Snapped flat belt | Happens quite often | Ten full mins | Hand tool |

| Tripped reset switch | Happens some times | One fast min | Just your hand |

| Dead tiny motor | Very rare to see | Half an hour | Test meter tool |

Step One Look for Thick Hair

This is the first spot I look at every time a friend calls me. It is the top cause of a bad jam on the floor head. The brush spins so fast on the rug to sweep the dirt up. It grabs loose long threads and long pet hair as it spins around.

The mess wraps tight on the hard plastic roll in a thick mat. It also ties up the metal side caps that help it spin smooth. Soon the thick drag gets way too strong for the tiny main motor. The roll gives up and stops dead in its tracks to stay safe.

How to Cut the Hair Free

You just need a good pair of sharp scissors from your desk drawer. A bright desk lamp helps a whole lot too so you can see. Put an old towel down on the floor to keep the room clean. Pull the main plug from the wall first to be safe.

Never work on a home tool that has live power in the cord. Turn the whole wide floor head up side down on the soft towel. Look at the brush roll for a thick dark mat of hair and string. Find the long cut line on the roll that runs end to end.

Run the sharp tip of your scissors down that long clear line. Cut all the way through the thick hair mat in one long slow slice. Use your bare hands to pull the gross mess out of the roll. Try to spin the round roll with your hand to see if it moves.

Make Sure the Roll Spins Free

The roll must spin smooth and light to work right on the floor. If it feels stiff you have hidden dirt deep inside the end caps. You must pop the small side caps off to clean them out well. Dirt acts like wet sand in those gears and slows them down.

Take a dry rag and wipe the round caps clean of all dark grit. Put them back on the flat ends of the roll when they are clean. Spin it one more time with your hand to check your fast work. It should spin like a top now with no drag at all.

Step Two Check the Drive Belt

If the round roll is clean but still stuck look right at this spot. The flat black belt joins the tiny main motor to the round brush roll. I have smelled hot rubber when this small part goes bad on the floor. The flat belt slips on the smooth steel pin and gets very hot.

When the belt snaps in two pieces you hear a loud pop sound. A dead broken belt will not turn the roll at all on the rug. You have to take the bottom base plate off to see it well. Grab a hand tool with a cross shape tip from your main tool box.

How to Find a Bad Belt Part

Take out the three small screws on the flat bottom base plate. Lift the flat plate up and look deep inside the main floor head. If the black belt is cut in half you found the big flaw. You must put a new clean one in to make it run right.

But at times the black belt looks fine to your eye at first glance. Push down hard on the dark belt with your bare thumb to test it. It should feel tight like a new rubber band straight from the box. If it sags down loose it is way too old to do the job.

A loose belt slips right off the round steel pin as it turns fast. It does not grab the roll tight on a thick deep house rug. You must toss it right out in the trash and get a new one. Do not try to reuse a bad stretched belt to save a dime.

Put the New Belt on the Tool

I buy spare belts to keep safe in my front desk drawer at home. They cost less than a cup of joe and save the day fast. Take the old loose belt off the round roll with your bare hands. Clean the main roll and the steel motor pin off with a dry rag.

Slide the new tight belt on the steel small motor pin first. Pull it hard back and slip it on the fat part of the roll. It takes strong hands to stretch it out far enough to fit tight. Spin the roll two times with your hand to line the belt straight.

Step Three Push the Reset Switch

A lot of these big floor care tools have a neat trick built in. They have a heat trip switch to keep the whole machine quite safe. Think of sucking up a thick wool sock by chance on the floor. The round roll stops in a blink of an eye when it gets stuck.

The tiny main motor still tries hard to spin it with all its might. The wires inside get hot in a flash and start to smoke a bit. The red switch trips to save the whole tool from a bad hot fire. It cuts the power off fast to save the day for you.

Where to Find the Red Button

Look down at the wide floor head base on the rug near your feet. Look near the back flat end or right on the smooth top side. You will spot a small square button there in a small round hole. It is most often bright red or pitch dark black on these tools.

Push it down hard with your thumb as far as it can go. You might hear a crisp click sound as it falls back in place. That crisp click is exactly what you want to hear at this stage. It means you reset the main heat switch to make it work.

Plug the long cord back in the wall socket near your front door. Turn the tool switch on and check the round roll on the floor. If it spins fast you fixed the whole thing with one small push. You can get right back to your home chores with a smile.

Step Four Check the Wand Plugs

This cool step is for the tall tools with a long flex soft hose. A tall floor tool has a long soft hose and a hard steel pipe. The wall juice has to run down to the wide floor head to run. It runs in thin wires hidden deep inside the long soft hose.

If the main juice fails the roll will not spin at all on the floor. The top head suction works fine but the floor sweep part is dead. You have to check the steel plugs to find the bad block in the line. This is a very fast thing to check with your bare eyes.

Clean the Dust Out of the Plugs

Take the tall steel pipe off the wide floor head with a firm pull. Look at the spots where the two main parts meet on the joint. You will see two small steel pins stick out on one flat end. You will also see two small round holes on the next flat part.

I find a lot of fine house dust stuck deep in these small round holes. Dirt blocks the raw juice from flowing right through the small steel pins. Take a clean dry cloth and wipe them clean of all the loose dust. Do not use wet soap on these parts at all or they will rust.

If a small steel pin looks bent fix it soft so it works right. Use small hand pliers to bend it straight back in to a clean line. Put the tall steel pipe back in the floor base with a hard push. Make sure it clicks tight so the strong juice flows good and free.

Step Five Test the Small Motor

If you did all the fast steps the tiny motor might be dead inside. This does not take place all that much in a clean home tool. It takes place on old tools that work way too hard on thick rugs. The parts inside just wear out from old age and long hard days.

To check this main part you must look deep inside the dark plastic shell. You need a small test tool with a glass screen on it to check. It checks for a good clear flow of juice on the thin bare wire. We call this a quick test for a clear main path on the line.

Table of Meter Test Facts

Here is a fast chart of what the clear glass screen might show you. This helps you know right off if the part is dead or still alive.

| Test Tool Read Out | What the Read Out Means | What You Must Do Next |

| Zero or loud beep | The wire path is good | Check the top hose pipe |

| Blank or open line | The tiny motor is dead | Buy a new motor part |

| Low volts on screen | The wall plug is bad | Check the main cord wire |

Change the Bad Motor Part

If the clear test screen says the part is dead you must choose fast. You can buy a new small motor on the web for less cash out. Or you can buy a whole new wide floor head that is pre built. Buying just the small part is less cash out of your pants pocket.

But putting it in takes a lot of time and care at your work desk. You must take the whole wide base block apart piece by small piece. You have to move small wires to the right spots to make it work. I think it is fun to build it back up with my own two hands.

But a lot of normal folks just buy the new wide head in a box. It snaps right on the tall steel pipe in a flash of a second. It is a much faster way to fix the mess and clean the floor. You save a lot of time and sweat that way on a hot long day.

Step Six Look at the Floor Switch

Some of these nice tools have a neat bare floor switch on the long handle. This switch stops the round roll from turning at all on hard flat wood. You use it when you clean hard wood floors or smooth stone tiles. The stiff brush can scratch your nice hard wood if it spins fast.

At times this small switch gets stuck on the wrong mode in the groove. Or it breaks deep inside the long hand grip where you grab the pipe. The switch moves a small block bar or a thin bare steel wire inside. Dust falls down in the switch crack day by day and builds up thick.

Clean the Switch Dirt Out

The thick dirt acts like hard rough sand in the small tight plastic gears. It jams the moving parts that need to slide smooth back and forth. You might push the thumb switch to the rug mode mark to sweep right. But the parts inside stay stuck on the bare floor mode out of sight.

The round roll will not spin if this takes place while you clean the room. Look at the long hand grip of your tall tool in bright room light. Find the thumb switch that says bare floor or deep rug mode. Slide it back and forth fast a few times to clear the track out.

This fast hard slide can clear the dirt out of the crack for good. If it feels stiff you must clean it out more with a strong air blast. You can spray a tiny bit of canned air right down in the crack. If the switch flops loose it is broken fast on the deep dark inside.

How to Care for Your Vacuum Tool

Once you fix the spin bug you must keep it clean all year round. I try to wash my main tool parts two times a year on the porch. The round roll gets very gross if you wait too long to wash it. Dirt and sand stick fast to the hard plastic and make it look bad.

This makes the whole floor head weigh a lot more when you push it. It makes the small motor work way too hard all day on the rugs. You can pull the roll out of the base head to wash it in the sink. Take the flat black belt off the steel pin first before you pull it.

Wash the Parts With Good Soap

Pull the round roll straight up and out of the wide dark floor head. Take the small side caps off and put them safe in a small glass cup. I take the main dirty roll to my deep white clean kitchen sink. I run warm tap water and drop in a small bit of clear dish soap.

I scrub the stiff brush parts with an old hard tooth brush I saved. The soap cuts the thick oil grease and the dark floor grime fast. Rinse it off a lot with clean warm sink water to get the soap out. You must let it dry out soft in the hot bright sun for a full day.

Keep It Dry and Safe

I leave it set in the hot sun for a full long day on the porch. Do not put it back in the tool base if it feels wet to your bare hand. Small drops of water will rust the steel balls in the side caps right fast. Red rust will ruin the smooth fast spin of the round roll brush part.

When it feels bone dry snap it back in place in the dark floor head. Put the clean side caps on and loop the flat black belt on the pin. Your tall tool will run like it just came from the main shop new. A clean kept tool lasts a long time and works great all year.

My Final Thoughts on This Quick Fix

A tall floor tool that will not sweep dirt is of no good use at all. It is a huge pain to push a dead tool round the large front room. The bad dirt just stays deep hidden in the thick soft rug threads. I hope my tales and quick tips help you fix yours fast right now.

Getting the gross hair out saves the day most of the bright sunny time. Keep a spare flat black belt near by just in case it breaks in half. Make sure to check the red trip switch on the wide base head first. These fast simple steps keep your hard cash safe right in your home bank.

You do not need to rush out to buy a brand new tool so soon. Just take your free time and look close at all the parts in the light. Give it a good hard try and see what you can fix on your own. You might surprise your own self with what you can build back up.