When people ask how an impact driver works, I think of real shops I’ve been in. I’ve stood in warm Florida garages. I’ve worked in cold Midwest drives. I’ve used tools in dry Arizona air. Each place shows you what torque and grip really mean.

I’ve used many tools over the years. I’ve tried drills. I’ve tried wrenches. I’ve tried drivers from big brands like Milwaukee, DeWalt, and Craftsman. Each tool feels a bit different in my hand.

The right tool can help you a lot. It can save time. It can keep you safe. It can even make the job more fun.

If you want to pick the best tool, here is what I learned. I tested them side by side. I took my time. And I kept things simple so you can do the same.

Table of Contents

What Is an Impact Driver and Why Do People Use It?

When I think of an impact driver, I think of real jobs. I used mine on deck frames in warm air. I used it on fence posts on cold mornings. Each time, the tool felt small and light. But it hit hard.

An impact driver has a 1/4-inch hex collet. It also has a hammer-and-anvil setup. This gives the tool more force than a drill. The key point is that an impact driver is a small tool with big power for screws and small lag bolts.

How It Differs From a Drill

When I switched from a drill to an impact driver, I felt the change fast. A drill gives steady torque. If the screw binds, the drill can twist my wrist.

An impact driver works in short hits. It stays easy to hold even when the screw meets hard wood. The key point is that a drill pushes back, but an impact driver stays in control.

Most Common Jobs in U.S. Homes

I use an impact driver for most home jobs. It drives deck screws fast. It handles framing screws with ease. It sinks lag screws without strain.

It also works in heat, cold, dust, or wet air. The key point is that an impact driver covers the most common screw jobs in many homes.

How Does an Impact Driver Work?

Here is the fast way I explain it. The tool spins like a drill at first. When the screw gets tight, the hammer slips, loads, and hits the anvil. Each hit adds torque. The motor never stops.

This cycle makes the “rattle” sound you hear. The key point is that the tool turns smooth motor speed into fast hits that break friction.

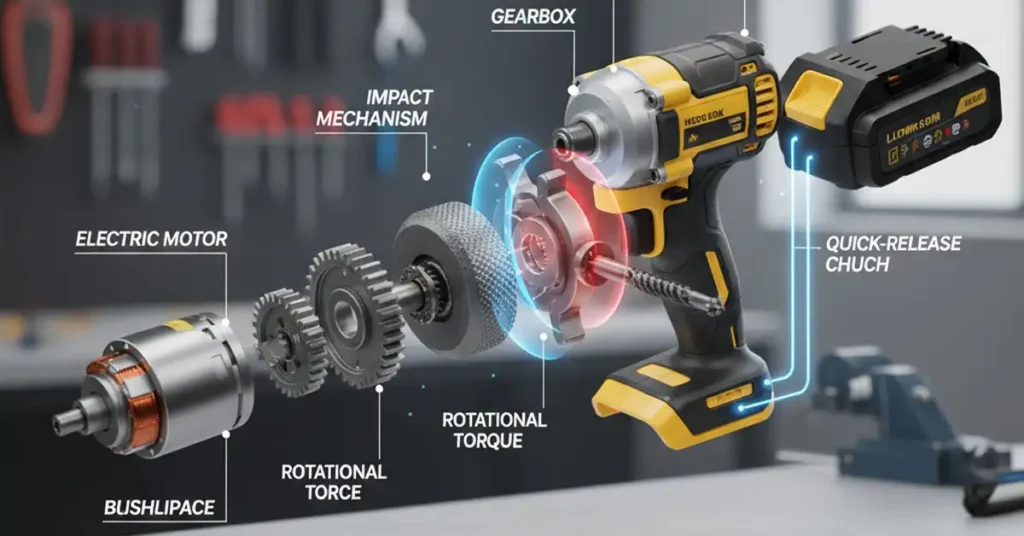

The 3 Parts That Create the Impacts

I took apart an old driver once. The inside was simple:

Motor: Spins fast with low torque.

Gearset: Slows the speed and builds torque.

Hammer and Anvil: Make the hits that drive screws deep.

The key point is that each part has one job. Together, they make strong and smooth force.

Why the Impacts Feel Smooth

At first, I thought the tool would shake a lot. It did not. The hits spin inside the tool. They do not shake my arm. I feel only a soft buzz.

The key point is that the force stays inside the tool, not in your hand.

What Happens Inside the Tool Step by Step?

Once I learned the steps, the sound and feel made sense. When the screw is easy, the tool runs like a drill. When the screw tightens, the hammer loads and hits the anvil. This can happen 2,500 to 3,500 times each minute.

The key point is that the tool shifts modes on its own to deal with tough spots.

Phase 1 — Low-Resistance “Drill Mode”

I see this when I drive screws into clean wood.

The hammer stays locked. The tool spins smooth. No hits fire. The sound is low and calm.

The key point is that drill mode handles light work.

Phase 2 — High-Resistance “Impact Mode”

This shows up when I hit knots or old studs.

The hammer climbs the ramp. The spring loads up. The hammer snaps forward. The anvil turns the screw a small step. The cycle keeps going.

The key point is that impact mode gives power only when the screw needs it.

Why This Stops Wrist Kickback

This is one big reason I trust an impact driver. A drill can twist your wrist hard. An impact driver does not do that.

The force stays inside the tool. The hammer strikes the anvil, not your hand. You only feel the motor’s low torque.

The key point is that the tool keeps your wrist safe while still pushing the screw through.

What Is the Hammer-and-Anvil System?

When I learned how an impact driver worked, this part shocked me the most. The hammer-and-anvil system sits in the center of the tool. It makes the strong hits you feel. The hammer holds energy as the tool spins. The anvil takes that energy and turns it into twist.

Brands like Milwaukee, DeWalt, and Makita tune this setup in smart ways. They change speed. They boost life. They cut shock. I have seen this on real job sites.

The key point is that this system is the heart of the tool and makes the power possible.

The Hammer (Rotating Mass)

I saw the hammer’s job when I opened an old driver.

It holds spinning energy. It moves back when the screw gets tight. It snaps forward and hits the anvil.

The key point is that the hammer builds and dumps force to break friction.

The Anvil (Output Shaft)

The anvil links to the 1/4-inch hex collet. That is where I slide in my bits.

It takes the hammer’s hits. It sends those hits to the bit. It is built to take thousands of blows.

The key point is that the anvil gives each twist hit to the screw.

The Spring (Energy Storage)

I feel the spring at work when a screw stops halfway.

The spring pushes down under load. It twists as it stores energy. It releases that force to make the impact hit.

The key point is that the spring loads and unloads to fire each strike.

Why Does an Impact Driver Feel So Strong for Its Size?

Small drivers still shock me with their strength. They turn fast motor spin into short, sharp torque hits. These hits start long screws clean. They loosen old deck screws. They sink lags into studs. My wrist feels safe the whole time.

Even in tight home spaces, the tool feels strong. A drill cannot match it.

The key point is that the driver’s power comes from quick hits, not raw motor force.

Torque vs. IPM Explained Simply

I learned this by testing two drivers in the same board.

Torque is twist force. IPM is hits per minute. More hits make the tool feel smooth.

The key point is that torque does the work, but IPM keeps the job clean.

Why It Beats a Drill in Dense Material

I have driven screws into oak and old studs. A drill fights there.

Impacts break stuck spots. The motor does not stop. My wrist stays safe.

The key point is that impacts keep the tool moving in hard material.

When Should You Use an Impact Driver?

An impact driver shines when the screw starts to fight back. I use mine for framing. For deck boards. For fences. For shop builds.

It helps in cold mornings. It helps in humid air. It helps with rust. When a drill slows down or twists, I switch.

The key point is that an impact driver saves time and cuts strain when things get tough.

Best Use Cases in U.S. Homes and Workshops

I grab my driver for the same jobs again and again:

- Deck boards

- Lag screws

- Rusty fasteners

- Long structural screws like GRK, SPAX, or LedgerLOK

The key point is that these jobs need strong, clean torque that a drill cannot give.

When Impact Drivers Save Time

Some tasks feel hard without one.

- Fast screw work

- Overhead work

- Outdoor jobs in heat, cold, or wet air

The key point is that the tool cuts strain and speeds up any job with lots of screws.

When Should You Not Use an Impact Driver?

I learned fast that an impact driver is not for every job. The hits are strong. That strength can cause harm. I have pushed small screws too deep. I have split soft wood. I have made rough holes when I tried to drill with it. It is also not safe for lug nuts or big bolts.

The key point is that impact drivers give force, not fine control.

Tasks Where a Drill Is Better

Some jobs need smooth, clean power. For these, I grab a drill.

- Clean drilling

- Hole saws

- Precise holes

- Soft wood that splits with hard torque

The key point is that a drill gives control when you need accuracy.

Tasks Where an Impact Wrench Is Required

I learned this while helping a friend with his car. An impact driver is not made for auto bolts.

- Lug nuts

- Brake caliper bolts

- Rusted steel bolts

- Heavy steel joints

The key point is that big bolts need the high torque of an impact wrench.

What Bits Should You Use With an Impact Driver?

I broke a lot of bits before I learned this lesson. Standard bits cannot take the hits. Impact bits can flex, and that flex helps them last. I like Milwaukee Shockwave, DeWalt FlexTorq, and Makita Gold in real work.

The key point is that impact-rated bits are built for the hits.

Why Regular Bits Break

Standard bits fail fast under impact.

- They are hard with no flex.

- The hits add stress.

- Small cracks form and grow.

The key point is that regular bits cannot absorb shock.

Signs You’re Using the Wrong Bit

I see the signs long before a bit snaps.

- Fast dulling

- Broken tips

- Stripped screw heads

The key point is that damage and cam-out mean you need impact bits.

How Does an Impact Driver Prevent Stripped Screws?

Stripped screws used to be a big problem for me with drills. The bit would slip and chew the screw head. Impact drivers act in short hits. Between hits, the bit drops back into the screw head. That tiny reset stops slip, even in tough wood or old screws.

The key point is that pulsed force keeps the bit seated.

Why Pulsed Force Helps

I felt this the first time I drove screws into dense studs.

- The bit gets a small pause.

- It resets and grabs.

- The grip stays clean.

The key point is that micro-pauses help the bit bite.

How to Avoid Cam-Out

These simple habits stop stripping.

- Use the right bit.

- Push forward with steady force.

- Keep the bit straight.

The key point is that good technique and good bits work together.

What Safety Tips Should You Follow?

When I first used an impact driver, it felt safe. It kicked back less than a drill. But I still learned fast that I had to respect the tool. I wear eye protection every time. I keep my hands clear. I let the tool work at its own pace. I keep the bit straight.

The key point is that impact drivers feel safe, but they still need good habits.

U.S. Safety Guidelines (OSHA/ANSI Habits)

These simple habits keep me safe in warm garages and cold driveways:

- Eye protection

- Rated bits and sockets

- Solid footing on ladders

- No damaged bits

The key point is that small steps keep you safe and in control.

What Features Should You Look for in an Impact Driver?

I have tried many drivers. I used Milwaukee, DeWalt, Makita, and Craftsman. Each one had new features. Speed modes helped me stay in control. Brushless motors stayed cool in summer heat. Small bodies helped me work in tight studs.

The key point is that the right features make the tool fit your work.

Speed and Power Modes

I use low mode for small screws. I use high mode for deck boards. I use self-tapping mode for metal.

The key point is that speed modes let you control power.

Brushless Motor Benefits

Brushless motors changed my work.

- They stay cool.

- They give more torque.

- They save battery life.

The key point is that brushless motors make the tool strong and efficient.

Compact vs. Mid-Torque Drivers

Compact drivers help me in tight spots. Mid-torque drivers help me in heavy wood. Mid-torque also helps with long screws.

The key point is that size changes power and reach.

FAQs: Impact Driver How It Works

What is the simple explanation of how an impact driver works?

An impact driver spins like a drill until the screw gets tight. Then the hammer slips, loads, and hits the anvil. These short hits add torque without twisting your wrist. The key point is that the tool gives fast bursts of force only when the screw needs it.

Why does an impact driver hit instead of spin smoothly?

It hits because the hammer-and-anvil setup needs resistance. When the screw pushes back, the hammer climbs the ramp and strikes. Each strike breaks friction and moves the screw. The key point is that impacts start only when the screw gets tight.

What makes an impact driver stronger than a drill?

A drill gives steady torque and can stall. An impact driver gives pulsed torque. These pulses break friction and keep the screw moving. Even small models feel strong. The key point is that pulses create more real-world force than smooth spin.

Can an impact driver drill holes?

Yes, but only for simple work. It can drill small pilot holes in soft wood. But it does not make clean holes. It can chip bits or split wood. I use a drill when I need clean edges. The key point is that an impact driver is not a fine drilling tool.

Why does an impact driver make a loud clicking sound?

The sound is the hammer hitting the anvil. Each click is one impact. The hits fire fast under load. The sound means the tool is working right. The key point is that the click is normal and shows the impact system in action.

Final Thoughts: Why the Impact Driver Works So Well in Real Jobs

When I think back on decks, fences, and shop builds, I see why the impact driver stayed in my hand. It gives big power in a small tool. The hammer-and-anvil setup keeps my wrist safe. It stops stalls. With good bits and good habits, it becomes a tool I trust.