I still remember the first time I cut a steel pipe. I was in a rush. I grabbed my grinder and just went for it.

It did not go well.

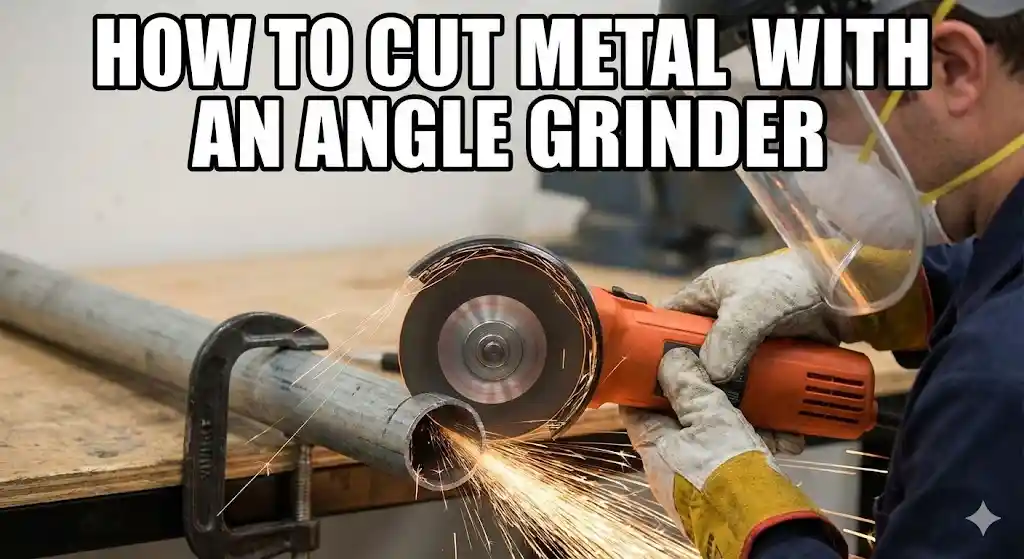

The tool kicked back. It jumped out of my hands. A piece of the disc broke off and hit the wall. My hands were shaking. I was lucky I did not get hurt.

I learned a big lesson that day. You must respect the tool.

Now, I use my DeWalt DWE402 almost every day. I have learned how to use it safely. If you are scared of the sparks or the noise, that is normal. I was too.

Here is how I solved the biggest problems I faced when learning how to cut metal with an angle grinder.

Problem 1: The Cut Is Too Slow

The Issue: You push down hard. Sparks fly everywhere. But the blade barely cuts the metal. The steel gets red hot.

Why This Happens

I made this mistake often. I was using the wrong disc.

Grinder discs are not all the same.

- Thick Discs: These are for grinding. They are about 1/4 inch thick. They scrub the metal. They do not slice.

- Thin Discs: These are for cutting. They are very thin. They look like a stiff CD.

If you use a thick disc to cut, it creates too much heat. It is like trying to cut a steak with a spoon.

My Fix

Check your disc. Look at the label.

For steel, I use a .045-inch cut-off wheel. It is very thin. It cuts fast. It does not heat up the metal as much. When I put the right wheel on my DeWalt, it felt easy. The blade did the work, not my muscles.

Note: Check the date on the metal ring. Discs expire. Old discs can break. If it is old, throw it away.

Problem 2: The Tool Jumps (Kickback)

The Issue: You are cutting a pipe. Suddenly, the grinder jerks hard. It feels like it wants to jump at your face. This is called kickback.

Why This Happens

Metal moves when you cut it. Gravity pulls it down.

If you cut a long bar, the two ends might droop. As they droop, the cut closes up. It pinches the blade. The blade gets stuck, but the motor keeps spinning. This makes the tool jump back at you.

My Fix

You have to think about gravity.

Do not cut in the middle.

If you put a bar across two tables and cut the center, it will fold. It will pinch the blade.

Let the waste fall.

I clamp the piece I want to keep. I let the scrap piece hang off the edge. When I cut, the scrap piece falls down. This opens the cut. The blade stays free.

Problem 3: The Edge Is Sharp and Ugly

The Issue: You finish the cut. The edge is jagged. It is wavy. There are sharp metal bits (burrs) hanging off it.

Why This Happens

I used to rush. I tried to cut through the metal in one go. I pushed the blade deep right away.

This is bad. The sides of the blade rub against the metal. This makes the blade wobble. A wobbling blade makes a crooked cut.

My Fix

I use the “score” method now.

- Mark it: I draw a line with a white marker.

- Score it: I gently drag the spinning blade across the line. I make a shallow groove first.

- Go back and forth: I move the grinder back and forth in the groove.

I do not push hard. I let the weight of the DeWalt do the work. The cut ends up smooth and straight.

Quick Guide: Which Disc Do I Need?

I get asked about diamond blades a lot. Are they worth the money? Here is what I found in my shop.

| Feature | Standard Disc | Diamond Disc |

| Price | Low ($3) | High ($20) |

| Life | Short | Very Long |

| Size | Gets smaller as you use it | Stays the same size |

| Speed | Fast | A bit slower |

| Dust | Lots of black dust | Less dust |

| Best For | Quick jobs | Daily use |

My Take: For small jobs, buy the cheap standard discs. They are fast. For big jobs, buy a diamond disc.

Problem 4: My Arms Get Tired

The Issue: You hold the grinder too tight. Your arms burn. You feel like you are fighting the tool.

Why This Happens

You are standing stiff. An angle grinder acts like a gyroscope. It wants to stay flat. If you fight it with stiff arms, you will get tired. When you are tired, you make mistakes.

My Fix

I changed how I stand.

- Feet wide: I stand with my feet apart. I feel stable.

- Move the guard: I turn the guard on the grinder. I make sure sparks fly away from me.

- Relax the grip: I hold the handle firm, but I do not squeeze too hard.

Safety Tip: I always wear a full face shield. Glasses are not enough. A broken disc can hit your neck. A face shield stops that.

Final Thoughts

Cutting metal is loud. It is hot. But it works well if you are smart.

Stop fighting the tool. Use a thin wheel. Support the metal so it does not pinch. Wear your face shield.

My DeWalt DWE402 is now my favorite tool. It saves me so much time. Follow these tips, and you can cut metal safely too.

FAQs: How to Cut Metal With an Angle Grinder

Can I cut metal with an angle grinder?

Yes, you can. It works well on steel. Use a thin cut-off wheel. Hold the tool firm with two hands. Watch for hot sparks. It is a fast way to cut old metal pipes.

What disc do I need to cut metal?

You need a thin cut-off wheel. Look for type 1 or 41. Do not use a thick disc. A thin disc cuts fast and stays cool. It makes the job safe and very easy to do.

Is it safe to cut metal without a guard?

No, it is not safe. Never take the guard off. It stops hot sparks. It blocks broken disc bits too. The guard keeps your hands and face safe while you work on it.

Why is my angle grinder not cutting?

Your disc might be too thick. Thick discs are for grinding. They do not cut well. Get a thin wheel. Do not push hard. Let the tool spin fast to cut clean and deep.

Do I need a face shield for grinding?

Yes, you do. Glasses are not enough. Hot sparks fly fast. A disc can break at any time. A full shield saves your face. It is a must for safe metal work in the shop.