It was 2:00 PM on a Saturday. I stood in my bathroom. My clothes were messy. I stared at a big problem.

I had one piece of tile left to put in. Just one.

But it was not a simple square cut. It was a shape like an “L.” It had to fit around the door frame.

I looked at my snap cutter. It is a great tool for straight lines. But for this shape? It is useless. I tried it on a scrap piece anyway. Snap. The corner broke off. I wasted five dollars in three seconds.

I did not want to rent a big wet saw. I looked at my shelf. I saw my DeWalt DWE402 angle grinder. I knew this tool could save my day.

Here is how I learned to cut tile with a grinder. It is fast, and it saves money.

The Problem: Why Snap Cutters Fail

We need to know why the tile breaks first.

Tile is hard. A snap cutter bends the tile to break it. This works for straight cuts. But you cannot bend a corner. The tension has nowhere to go.

If you try to snap an L-shape, the crack runs wild. It ruins the whole piece.

Why it fails:

- Tension: Bending breaks the wrong part.

- Shape: You cannot snap a corner.

- Hardness: Tile is dense. It hates to bend.

This is why we need a grinder. We must cut it, not snap it.

The Solution: The Grinder Method

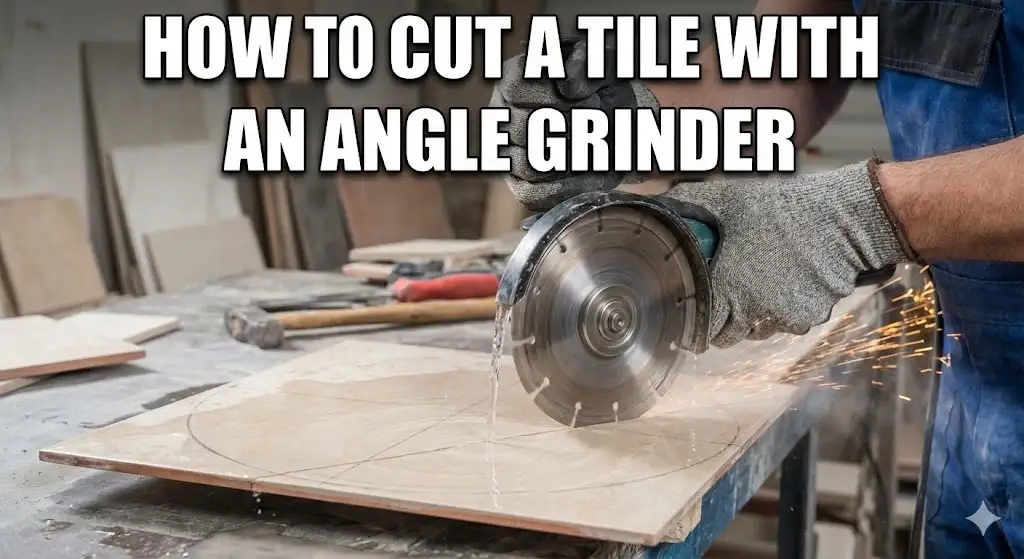

Using a grinder is loud. It makes dust. But it is very precise.

Here is the step-by-step way I did it.

1. Safety First (Do Not Skip)

The dust is bad.

Cutting dry tile makes silica dust. It tastes like chalk. It hurts your lungs. I went outside to the driveway. If you must be inside, use a vacuum near the blade.

My Gear:

- Tool: DeWalt DWE402 Angle Grinder. (I like it. It stops if I drop it).

- Blade: 4.5-inch Diamond Blade.

- Note: Get a “Continuous Rim” blade. It is smooth. Do not use a blade with gaps. It will chip the tile.

- Safety: Glasses, a good mask, and earplugs.

2. The Tape Trick

I grabbed my blue painter’s tape. This is my secret.

I put tape over the spot I needed to cut. Then, I drew my line on the tape with a pencil.

Why this works:

The tape holds the glaze together. The blade vibrates a lot. The tape acts like a shock absorber. It stops the tiny chips.

3. Hold It Down

I clamped the tile to my table. I made sure the cut area hung over the edge.

My past mistake: Once, I cut a tile flat on wood. I cut into the wood. The vibration got bad. The tile cracked. Always let the waste piece hang free.

4. The Cut: Score It First

This is the most important part. I turned on the DeWalt. I let it get to full speed.

I did not just push through. I used a trick. I call it “The Glaze Score.”

Step A: The Scratch

I held the grinder tight. I dragged the blade lightly across my line. I did not push down. I just wanted to scratch the top. I made one pass. I cut just the top layer.

This makes a small groove. The blade will want to stay in this groove.

Step B: The Deep Cut

Now, I went back and forth. I treated it like sanding wood. I let the tool do the work.

- Listen: If the motor sound drops, you are pushing too hard. This creates heat. Heat cracks tile.

- Move: Keep the blade moving. Do not stop in one spot.

Step C: The Drop

I got deeper. I felt the tile give way. The waste piece fell onto the grass.

5. Smooth the Edge

I looked at my cut. It was straight. But it was sharp.

I turned the grinder on again. I used the flat face of the blade. I rubbed it gently on the cut edge. It acted like sandpaper. It made the edge smooth.

Why It Worked

I wanted to know why this was better than a wet saw. I looked at the facts.

Here is a simple table to compare them.

Table: Tools for Corner Cuts

| Tool | Precision | Risk of Cracks | Mess | Cost |

| Angle Grinder | High | Medium | High (Dust) | Low |

| Wet Saw | Medium | Low | High (Water) | High |

| Snap Cutter | Low | High | Low | Very Low |

Troubleshooting: When It Goes Wrong

I have broken many tiles. Here is what I learned.

1. The Burn Mark

- Problem: The edge turns black.

- Cause: The blade is dull. Or you push too hard.

- Fix: Slow down. Cut lightly.

2. The Corner Crack

- Problem: The tile snaps at the inside corner.

- Cause: Vibration. The corner is weak.

- Fix: Drill a small hole at the corner first. This stops the stress.

3. The Wobbly Line

- Problem: The cut is not straight.

- Cause: Your arms are stiff.

- Fix: Relax your arms. Move your whole body. It helps you aim.

My Final Thoughts

I wiped the dust off the tile. I put it near the door. It fit perfectly.

Using a grinder is scary at first. It is loud. But it is a great skill. You can cut any shape you want. You can cut circles for pipes. You can cut vents.

FAQs: How to Cut a Tile With an Angle Grinder

Can I cut tile without water using an angle grinder?

Yes, dry cutting works well. You need a diamond blade. Do it outside to avoid the dust. Wear a good mask. It creates a lot of mess, but it is very fast. It is a handy skill for home repairs.

What is the best blade for cutting porcelain tile?

Buy a continuous rim diamond blade. It has a flat edge with no gaps. This prevents chips on the tile. Do not use a wood blade. It will ruin your work. A DeWalt blade is a solid choice to buy.

How do I stop the tile from chipping when I cut?

Put blue tape on the tile line. Score the top layer first. Do not push hard on the tool. This keeps the edge clean. It stops the tile from cracking. It is the best way to get a smooth cut.

Can an angle grinder cut curves or circles?

Yes, grinders are great for curves. Make small cuts to remove pieces. Then grind the curve smooth. It is perfect for cutting holes for pipes or drains. Go slow to keep the shape right.

Is using an angle grinder on tile dangerous?

It is safe if you use gear. Wear eye glasses and ear plugs. Hold the tool with both hands. Do not force it. Let the blade do the work for you. Always unplug it when you change blades.