It was a crisp Saturday morning. I had a tall stack of logs in the driveway and a long day of work ahead. I grabbed my saw, ready to cut.

I pulled the cord. The engine sputtered. I pulled again. It started, but as soon as I hit the gas, it died. The silence was loud. I could smell unburnt fuel. I felt the heat rise in my face. It wasn’t the wood that was the problem. It was my tool.

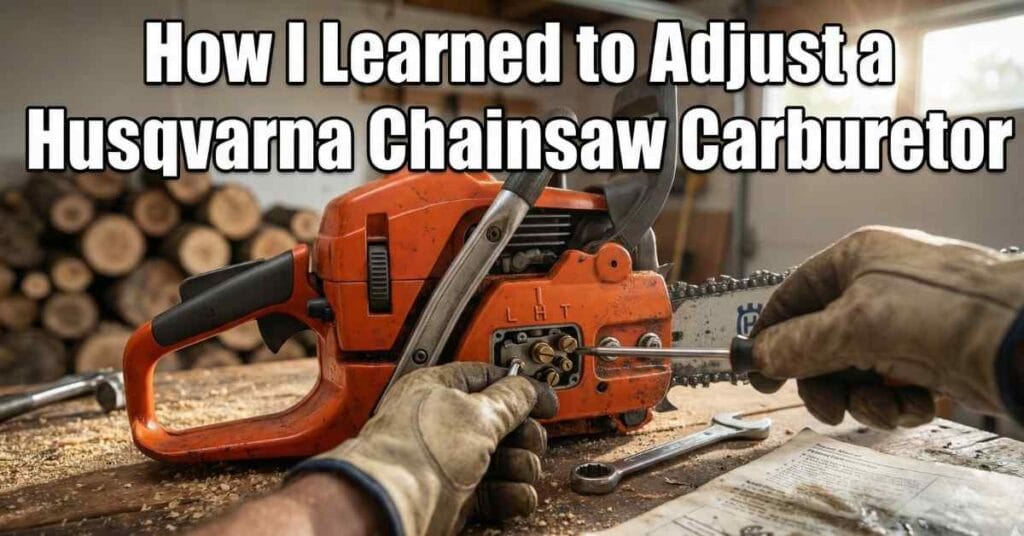

I realized I had to adjust a Husqvarna chainsaw carburetor myself. I was nervous. I didn’t want to break it. But after some trial and error, I found it is not magic. It is just listening.

Here is how I fixed my saw and got back to work.

The Mistake I Made First

Before I touched a single screw, I learned a hard lesson. Never tune a dirty saw.

Years ago, I tuned a saw that had a clogged air filter. It ran great that day. But when I cleaned the filter later, the saw got too much air. It ran too hot and I almost ruined the engine.

So, standing in my driveway, I did this first:

- I cleaned the air filter. I washed it with warm soapy water.

- I checked the gas. I made sure the tank had fresh mix.

- I warmed it up. I let the engine idle for five minutes. You cannot tune a cold engine.

The Three Magic Letters

On the side of my saw, I saw three holes. They are marked L, H, and T.

- L (Low): Helps the saw start and speed up.

- H (High): Gives the saw power while cutting.

- T (Idle): Keeps the saw running when you let go of the trigger.

Step 1: Fixing the Bog (The “L” Screw)

My main issue was the “bog.” I would pull the trigger, and the saw would gasp for air.

To fix this, I used the L screw.

- I let the saw idle.

- I slowly turned the L screw clockwise. The engine speed went up. It started to sound like it was racing.

- Once I heard that high speed, I stopped.

- Then, I turned the screw back counter-clockwise just a tiny bit (about 1/4 turn). The engine slowed down and sounded deeper.

The Test: I snapped the throttle trigger fast.

My Result: The saw roared instantly. No lag. If it had hesitated, I would have turned the screw a little more to the left (counter-clockwise).

Step 2: Safety First (The “T” Screw)

After the first step, I noticed something scary. The chain was spinning while the saw sat on the ground. That is dangerous.

I went to the T screw. This one is easy.

- I watched the chain.

- I turned the T screw to the left (counter-clockwise).

- I kept turning until the chain stopped moving completely.

I made sure the engine still ran smoothly. I found the sweet spot where the engine purred, but the chain stayed still.

Step 3: The High Speed Hum (The “H” Screw)

This part made me sweat. The H screw controls the fuel at full power. If you get this wrong, you can burn up the piston.

I held the throttle wide open. The saw screamed. It was a high, clean whine. That sounds fast, but it is actually bad. It means the engine is starving for gas.

I turned the H screw to the left very slowly. I listened for a specific sound. Old woodcutters call it “burbling.” It sounds a bit rough, like a boat motor clearing its throat.

- The Scream: Too lean. Too hot. Danger.

- The Burble: Just right.

When I heard that rough burble at full speed, I knew I was safe. I tested it on a log. As soon as the chain hit the wood, the burble vanished. The saw pulled hard and smooth. It was perfect.

My Quick Cheat Sheet

Here is a table of what I look for when my saw acts up.

| What I Hear/See | The Likely Problem | My Quick Fix |

| Saw dies when I hit gas | L Screw is too lean. | Turn L screw Left. |

| Chain spins at idle | T Screw is too fast. | Turn T screw Left. |

| Saw screams / gets hot | H Screw is too lean. | Turn H screw Left. |

| Lots of smoke | H Screw is too rich. | Turn H screw Right. |

Final Thoughts

By the time I finished, the sun was high. I wiped the sawdust off the cover. I pulled the cord one last time. It started on the first pull.

The saw felt like new. I cut through that oak pile in record time. There is a real pride in fixing your own tools. You save money, but you also learn to trust your hands.

FAQs – How I Learned to Adjust a Husqvarna Chainsaw Carburetor

Why does my Husqvarna chainsaw bog down when I give it gas?

If your saw bogs, it is hungry for fuel. The L screw is likely set too lean. Turn the L screw to the left a tiny bit. This adds gas to the mix. It helps the saw rev up fast without a pause.

What do the L, H, and T screws do on my saw?

On a Husqvarna chainsaw carburetor, L is for low speed. H is for high speed. T is for idle. L helps it start. H gives it power to cut wood. You must adjust all three to make the saw run right.

Which way do I turn the screws to add more fuel?

To add fuel, turn the screw left. This makes it rich. To cut fuel, turn it right. This makes it lean. Adjust your Husqvarna chainsaw carburetor slowly. Listen to the sound. Small turns do a lot.

Why is my chainsaw chain spinning when it idles?

The idle speed is set too high. The T screw pushes the throttle. Turn the T screw to the left until the chain stops. Your Husqvarna chainsaw should idle well without the chain moving. This is safe.

Do I need a special tool to adjust my carburetor?

Many new Husqvarna chainsaws need a splined tool. Old ones use a flat screwdriver. Check the screw heads first. You need the right tool to adjust the carburetor. Do not force the screws or they break.