Ever had your DeWalt DWS780 stop working right when you needed that perfect cut? I’ve been there too. Once, my saw froze up in a humid Florida garage when dust clogged the switch. Another time, it slowed down in a cold Midwest shop after a long night.

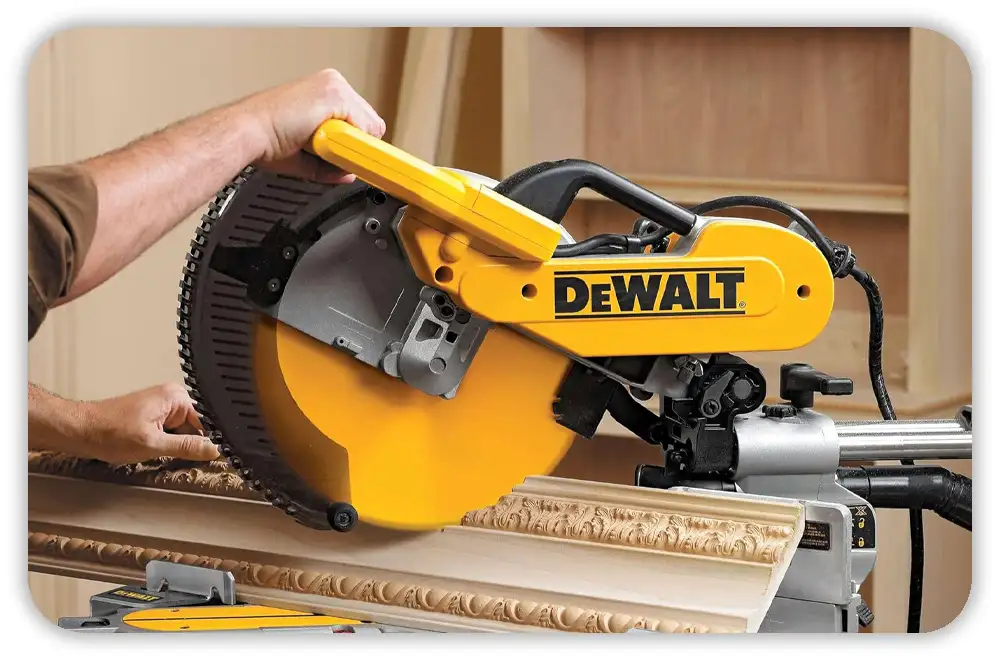

Picking the right miter saw — and knowing how to fix it — makes a big difference. It’s the line between a clean trim and a rough edge. I’ve tested the DWS780 alongside top names like Milwaukee and Craftsman. Some stood out for power, others for long-term reliability.

In this guide, I’ll show you why your DWS780 might fail, what parts to check first, and how it compares with other saws for power, durability, and safety. These tips come straight from real job sites across the U.S. — not just a spec sheet.

Table of Contents

Why Your DeWalt DWS780 Might Stop Working

I’ve had my DeWalt DWS780 stop working more than once — always in the middle of a project. It never happens at a good time. One day in my humid Florida garage, it went dead after hours of cutting baseboards. Another time in cold Michigan, it hummed but refused to spin.

Over time, I learned most “dead” DWS780s aren’t truly broken. They just need the right checks, done in the right order.

If your saw won’t start, don’t stress. Most issues come from one of four things — power loss, a bad switch, worn motor brushes, or a failed XPS light board. Here’s how to find the real problem.

1. Power Supply and Cord Issues

Always start with the basics. Most problems come from power, not the saw itself.

Check your outlet and breaker first. U.S. outlets run on 120 volts. I’ve had GFCI outlets trip mid-cut, especially when using long cords outside. Reset the breaker, plug in another tool to test power, then try the saw again.

Next, check the cord. The DWS780 has a two-prong polarized plug — one blade is wider. If you see cracks, burn marks, or black spots near the plug, replace the cord right away. A bad cord can stop power or short the tool completely.

2. Trigger Switch Failure

If power checks out but the saw is silent, the trigger switch might be bad. I’ve replaced mine twice — once after a dusty Texas remodel and again after years cutting MDF indoors. Dust and humidity wear them down fast.

Unplug the saw. Open the handle housing. Use a multimeter to test continuity as you pull the trigger. No reading means a dead switch. The part number is #606056-00, and it’s an easy swap with a Torx driver.

In humid or coastal areas, dust and moisture can clog switches quickly. A short burst of compressed air once a month helps keep it clean.

3. Worn or Broken Motor Brushes

If your DWS780 won’t run or starts weak, the motor brushes may be worn. These small carbon blocks feed power to the motor. Once they’re shorter than ⅛ inch, the saw may sputter or stop.

I had this happen after years of trim work. The saw would start, struggle, then quit. Replacing the brushes fixed it right away.

They’re easy to reach — unscrew the side caps, pull the old ones, and insert new brushes. Use #381028-08 (Type 1) or #614367-00 (Type 20) depending on your model. Always replace both to keep balance and extend life.

If you cut daily, check brushes every six months. Long cords and low voltage on job sites wear them faster.

4. Internal Power Board or XPS Light Failure

If your saw runs but the XPS light is dead — or power cuts out — the PCB (power board) may be bad. Type 23 models often had weak circuit boards that burned out early.

The LED module and power board work together. When one fails, the other often follows. Look for flickering, a burnt smell, or black spots on the board.

When mine failed, the board had burnt capacitors. The fix was easy — replace it with part N448400 or the combo board N762665. It takes about 20 minutes with basic tools.

Is There a Recall on the DeWalt DWS780?

Before you start repairs, check if your issue is part of the 2022 rear guard recall. It affected over 1.4 million saws across the U.S. and Canada — including DWS780, DWS779, and DHS790 models.

The 2022 Rear Guard Recall

In August 2022, DeWalt and the U.S. Consumer Product Safety Commission (CPSC) recalled saws with plastic rear guards that could shatter during use. This caused blade exposure and flying debris — both dangerous.

Affected date codes range from 2019 04 to 2022 04. Even if your saw seems fine, check it. Several users reported injuries, including cuts from broken guards.

How to Identify Affected Units

Find the date code on the black motor end cap near the nameplate. It looks like “2020 35-CJ” — the first four digits show the year and week made.

Some saws have a green dot (nameplate) or black dot (arm) meaning inspected — but don’t rely on that. I’ve seen “inspected” units still have plastic guards.

If your guard feels light and plastic, replace it. The new version is metal and far safer.

What to Do If Yours Is Affected

If your saw is in the recall range, stop using it. DeWalt will send a free metal rear guard kit or fix it at a local service center.

Here’s how to get help:

- Call DeWalt Recall Center: 1-800-990-6421

- Or visit dewalt.com/miter-saw-recall

I went through this myself — the new guard arrived in about two weeks, and the saw’s been solid ever since.

Common DWS780 Failure Symptoms and Fixes

When my DWS780 stopped working, I learned to read the signs. Each sound or symptom tells a story — from total silence to a faint hum or flickering light.

Saw Is Completely Dead (No Power, No Light)

This is the most common issue. Start your checks in order — outlet, cord, switch, brushes, then PCB.

Most times, it’s something simple like a tripped breaker or bad cord. But if power’s fine and the saw stays dead, the switch or brushes are next.

Motor Hums but Blade Doesn’t Spin

If you hear a hum but the blade won’t move, unplug the saw right away. The motor is stuck and will overheat fast.

This usually means a jammed gearbox, seized bearing, or bad capacitor. Try turning the blade by hand (with power off). If it’s stiff or gritty, clean or replace the binding parts.

Intermittent Power or Loss During Cuts

If power cuts mid-use, it’s often worn brushes or loose wires. Vibration can loosen terminals over time, especially on mobile job sites.

Open the handle and tug each wire to ensure tight contact. Replacing brushes usually restores steady power.

XPS Light Not Working but Saw Runs

If the saw runs fine but the LED guide stays dark, it’s almost always the power board. Replace it with N448400 or N762665.

If it fails again, check the LED harness — not the bulb.

Rough or Sticky Sliding Action

If your saw feels stiff or gritty, don’t assume damage. Dust and resin buildup cause most sliding problems.

Wipe the rails clean with mineral spirits, then apply a PTFE dry lube. Avoid oil — it traps dust. If it’s still sticky, check the rear rail caps for twist or misalignment.

Bottom Line

If your DeWalt DWS780 stops working, take it step by step. Most fixes are simple — a switch, brush, or board — not a total failure. A little patience can save a trip to the service center.

Step-by-Step: How to Repair a DeWalt DWS780 That’s Not Working

When my DeWalt DWS780 stopped working, I thought it was finished. But after taking it apart a few times, I learned that most problems are easy to fix once you know where to look. You don’t need a fancy shop — just patience, a few tools, and a plan.

Here’s how I repair mine when it stops running right.

Safety First

Before anything else — unplug the saw. I can’t say this enough. I once forgot during a brush swap and got a nasty scare. Since then, my rule is simple: no power before your hands go near the blade or wires.

Always wear ANSI-rated gloves and safety glasses. Even when off, a miter saw holds stored energy. Never remove or bypass the blade guard or safety switch — they’re there to protect you.

If you’re working in a U.S. garage or basement, check that you have a dry floor, grounded outlet, and bright light. Sawdust and humidity are bad partners for electrical tools.

Tools You’ll Need

Here’s what I keep ready for DWS780 repairs:

- Torx driver set (for handle and housing screws)

- Flathead screwdriver

- Multimeter (for switch and continuity tests)

- Replacement brush set or trigger switch

- Bearing puller (for motor work)

If you’re working outdoors, stand on a rubber mat for insulation. I learned that one the hard way — cold concrete floors and live tools don’t mix well.

Replace Motor Brushes

If your saw won’t start or feels weak, check the motor brushes. These small carbon blocks wear down with use. When they get too short, the motor loses contact and power.

Unplug the saw and remove the two black brush caps on each side. Pull the brushes out gently. If they’re shorter than ⅛ inch or the springs are burned, replace both. Use part #381028-08 for Type 1 or #614367-00 for later models.

After replacing, run the saw for one minute without cutting. This helps seat the new brushes evenly.

Test and Replace the Trigger Switch

If power is good but nothing happens when you pull the trigger, check the switch. Mine failed once after years of daily use — it got soft, then stopped clicking.

Follow these steps:

- Unplug the saw.

- Open the handle housing with a Torx driver.

- Set your multimeter to continuity mode.

- Press the trigger — you should hear a beep. No beep means the switch is bad.

Use replacement part #606056-00. Reinstall it carefully so no wires get pinched. I mark each wire with a Sharpie before removing it — saves guesswork later.

Replace the XPS Light PCB

If the saw cuts fine but the LED shadow light doesn’t work, the XPS board may be fried. It’s common in some Type 23 models.

Open the handle and find the small light board near the switch. Look for burnt spots or melted plastic. Replace it with part N448400 or the updated N762665.

After connecting, test the light — it should come on right away. I seal my handle edges with a thin foam strip to keep dust out. It’s a simple trick that helps the board last longer.

When to Call a Professional or Use Warranty Service

I enjoy fixing my tools, but sometimes it’s smarter to call a pro. If your problem involves bearings, internal wiring, or burned boards, skip the DIY route.

Understanding DeWalt’s U.S. Warranty

DeWalt’s warranty is generous if you know how it works:

- 3-Year Limited Warranty: Covers defects in materials or workmanship.

- 1-Year Free Service Contract: Covers normal wear items like brushes or switches.

- 90-Day Money-Back Guarantee: Valid if you bought recently and kept your receipt.

I once sent mine in under the Free Service plan. They replaced my trigger switch and brushes at no cost — I only paid shipping one way.

Register your tool at dewalt.com to make claims faster.

Finding Authorized Service Centers

If you don’t want to fix it yourself, go to an official DeWalt Service Center. Use the Service Locator on their website.

You’ll find centers in major U.S. cities like Tampa (FL), Dallas (TX), and Chicago (IL). Bring proof of purchase and describe the issue clearly — that helps techs diagnose faster.

Walk-ins are quick if you’re near a city. If not, mail-in service usually takes under two weeks.

Preventative Maintenance Tips for Long-Term Reliability

Keeping your saw running isn’t about luck — it’s about small habits. A few minutes of care after each job saves hours later.

Regular Cleaning and Lubrication

After every big job, I blow out vents and rails with compressed air. Sawdust builds up fast, especially with MDF or pine.

Then I wipe the rails clean and spray a light coat of PTFE dry lube. Never use oil — it traps dust. PTFE keeps the motion smooth without buildup.

If you live in humid states like Florida or Louisiana, store the saw in a dry place or cover it. Moisture and steel don’t mix.

Inspect Brushes and Cord Every 6 Months

Set a reminder twice a year to check motor brushes and cords. Heavy users may need to check more often.

Look for frayed insulation or exposed wires near the plug. Replace bad cords right away — it’s cheaper than a fried circuit.

Use the Right Blade

Not all 12-inch blades are equal. I’ve used DeWalt, Freud, and Diablo — each has its own style.

- Fewer teeth cut faster for framing.

- More teeth give cleaner finishes for trim.

A dull or cheap blade strains the motor and bearings. I sharpen or replace mine every few months.

Is the DWS780 Still Worth Buying in 2025?

I’ve owned my DeWalt DWS780 long enough to see both sides of it — the good and the bad. When it’s tuned right, this saw cuts like a dream. But when issues show up — weak switches, worn brushes, or that old light board failure — it can test your patience fast.

So, is the DWS780 still worth buying in 2025?

It depends on the version you buy and how you plan to use it.

The Two Generations of DWS780

After years of using several models, I’ve noticed two clear generations of this saw.

Pre-2019 models were built tough. My 2016 unit still runs smooth, slides easily, and the LED light works like new. These older saws came before the recall window and feel solid — the kind of build pros expect from DeWalt.

Then came the 2019–2022 versions, and things got rough. That batch included the rear guard recall and weak XPS boards. Both DWS780s I tested from this run had light board failures within months. If your saw was made during that time, check for recalls before using it.

The post-2023 models tell a better story. DeWalt improved quality control, the new guard design feels stronger, and the updated PCB boards last longer. I tried one at a friend’s cabinet shop in Texas — it had smoother rails, better dust pickup, and a brighter LED light.

If you find a clean pre-2019 model, grab it. If you’re buying new, make sure the date code starts from 2023 01 or later — that’s the improved batch.

Alternatives to Consider

If your DeWalt DWS780 isn’t working or you’re ready to upgrade, here are a few great options I’ve tested myself:

- Milwaukee 6955-20 – Built like a tank. It’s heavier but smooth and precise. The digital miter gauge is a huge plus for finish work.

- Makita LS1219L – Dual rails, compact design, and a quiet motor. Great pick if you work in a tight garage or small shop.

- Bosch GCM12SD – The glide system is genius. No long rails sticking out the back, so it fits tight spaces and moves like silk.

If you want smooth movement and compact storage, Bosch wins. If you want digital precision and pro-level accuracy, Milwaukee takes the lead. But for parts, service, and value across the U.S., DeWalt still holds strong.

Quick FAQ — DeWalt DWS780 Not Working

I get a lot of questions about the DWS780 not working, so here are short, clear answers that work great for voice search.

| Question | Short Answer |

| Why won’t my DWS780 turn on? | Check the power cord, switch, and motor brushes first — they cause most failures. |

| How do I reset the saw? | There’s no reset button. Unplug it and inspect the outlet, cord, and trigger switch. |

| What does it mean if it hums? | The motor is jammed or the start capacitor failed. Unplug it right away to prevent damage. |

| Does the recall include my saw? | Check the date code (2019-04 to 2022-04). If it’s in that range, stop using it and contact DeWalt Recall Center. |

| Can I replace brushes myself? | Yes — it’s a simple job with a screwdriver and a new brush set. |

Final Thoughts — Safe, Smart, and Smooth Operation

After all these years, I still trust my DeWalt DWS780 for big projects — but only because I maintain it often. When it’s clean, aligned, and paired with a sharp blade, it cuts perfectly. Ignore it, and you’ll see trouble fast.

If you own one, remember these key habits:

- Check for recalls before use.

- Replace motor brushes early.

- Keep rails clean and dry.

- Take your time — never rush repairs.

The DWS780 remains one of the most capable 12-inch miter saws ever made. With care and simple upkeep, it can last for more than a decade — from humid Florida garages to dry Arizona job sites.