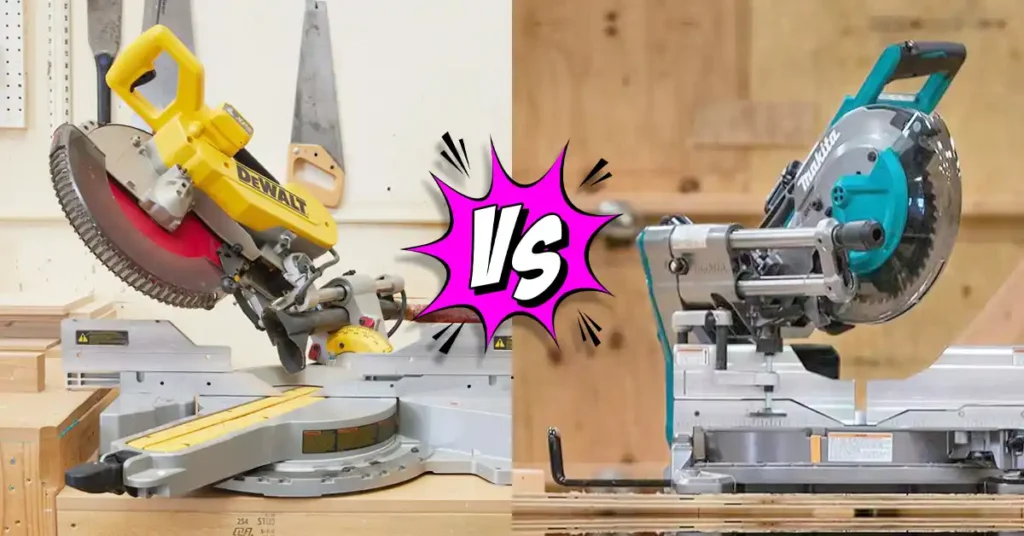

If you’ve ever stood in a tool aisle wondering whether to grab a chop saw or a miter saw, you’re not alone. I’ve been there too — more than once. At first, they look almost the same. Both have a big motor, a handle on top, and a spinning blade that cuts straight down into the workpiece. But once you use them side by side, the differences are easy to see.

When I set up my first workshop, I bought what I thought was the right saw — a heavy chop saw. It tore through steel with no problem, but when I tried it on a 2×4, it burned and smoked in seconds. Later, I switched to a miter saw and finally got the clean, smooth cuts I wanted for wood. That’s when I learned these two tools may look alike, but they do very different jobs.

Picking the right saw really matters. In humid Florida garages, metal tools can rust fast if you don’t care for them. In cold Minnesota winters, motors start slow. Out west, in dry and dusty Arizona job sites, abrasive wheels wear out quicker than you’d expect. The kind of work you do — and where you do it — makes a big difference.

My goal here isn’t to push one brand or say which saw is “better.” It’s to help you see what each one does best. After years of using both in real shops and garages, I’ve learned that the right choice depends on your work. Once you know the difference, you’ll cut smarter, faster, and safer.

Table of Contents

Basic Function of Each Tool — Chop Saw vs Miter Saw

Chop Saw

A chop saw is all about raw power. It makes quick, straight 90° cuts through metal and other tough materials. When I first used one on a job site, it felt like a beast — sparks flying, hot steel burning, loud and fast. Unlike a wood saw, it doesn’t slice. It grinds its way through using an abrasive cutting wheel.

Most chop saws plug into power outlets and have big motors that don’t slow down, even with thick steel or rebar. They’re heavy and steady, made to stay in one spot on a bench or job stand. You’ll see them in metal shops, plumbing setups, and framing crews that cut steel conduit or studs.

From my experience, a chop saw isn’t about finesse. It’s made for fast, straight cuts again and again. The trade-off is rough edges and lots of sparks. You always need good PPE — gloves, glasses, and sometimes a face shield. In damp garages or humid states like Florida, I always wipe mine down after use to stop rust.

In short: a chop saw is built for power and speed, not fine detail. It’s your go-to when you need to cut steel fast.

Miter Saw

A miter saw is about control and precision. Instead of grinding, it uses a sharp, toothed blade that slices wood cleanly. When I switched to one after using a chop saw, it felt like going from a chainsaw to a scalpel.

This saw shines when you need clean, angled, or compound cuts. Think trim, molding, door frames, or flooring — anywhere pieces must fit perfectly. You can turn the blade left or right for angles, or tilt it for bevels. That makes it a favorite for finish carpentry and detailed woodwork.

You can get miter saws in both corded and cordless models. Cordless ones — like those from DeWalt, Milwaukee, or Ryobi — work great for job sites without easy power. In colder northern shops, I’ve noticed batteries drain faster, but that’s normal.

A miter saw takes more setup time. You’ll check your angles, adjust fences, and sometimes recalibrate the scale for perfect accuracy. Once tuned, though, it makes repeat cuts with ease.

In short: a miter saw is built for clean, accurate cuts — perfect for wood when detail matters most.

Technical & Practical Differences — Chop Saw vs Miter Saw

When you use both tools often, their differences stand out fast. Here’s how they compare in real life — from job sites to home garages.

Performance & Precision

A miter saw gives smooth, exact cuts — great for wood and trim work. You can set angles for perfect joints. A chop saw is all about force. It cuts through steel with torque, not precision. The edges are rough, but that’s fine for metal jobs.

Power & Cutting Capacity

A chop saw wins on pure power. Its motor and abrasive wheel cut thick steel and pipes with ease. A miter saw depends on blade sharpness and high RPM for smooth wood cuts. It can’t handle steel but slices through wood or plastic beautifully.

Portability

Chop saws are heavy and best kept on a bench. Carrying one around is tough. Miter saws are lighter, and cordless models are easy to move. They’re great for remodels or trim work in multiple rooms.

Ease of Setup & Maintenance

A chop saw is simple — plug in, clamp the piece, and cut. No real calibration needed. A miter saw needs more care: check alignment, angle scales, and keep the blade clean. The effort pays off in perfect cuts.

Safety Considerations

Safety feels different with each. Chop saws shoot sparks and heat up fast. Always wear gloves, sleeves, and eye protection. Miter saws feel safer since the blade moves in a fixed path, but you still need to keep your hands clear and your workpiece tight.

Learning Curve

A chop saw is easy to learn — clamp and cut. It’s great for beginners cutting metal. A miter saw takes practice. You’ll need to master angles and bevels for perfect joints.

Real-World Context

From my time working in different climates, I’ve seen how weather affects tools. In humid Gulf Coast garages, miter saw fences can rust fast. In dusty Arizona, chop saw wheels wear down quicker. In cold Midwest winters, miter saw bearings stiffen up if unused. Keeping your tools clean, dry, and covered helps them last longer.

Comparison Table — Chop Saw vs Miter Saw

| Feature / Factor | Chop Saw | Miter Saw |

| Accuracy | Best for straight, repeat cuts | Great for angled, detailed cuts |

| Power Source | Usually corded electric | Corded or cordless |

| Portability | Heavy, bench-based | Light and easy to move |

| Safety | Sparks and heat; full PPE needed | Lower kickback risk |

| Ideal Use | Metalwork, rebar, steel framing | Trim, molding, wood framing |

When to Use Each — Chop Saw vs Miter Saw

Knowing when to use a chop saw or a miter saw can save you time and frustration. They may look alike, but they handle very different jobs.

When to Use a Chop Saw

I grab my chop saw when the job needs power over precision. It’s perfect for cutting steel conduit, rebar, or angle iron — anything tough that needs a clean 90° cut. On busy job sites or home welding projects, the chop saw is a true workhorse.

If I’m outdoors or in a well-ventilated garage, I don’t mind the sparks or noise. But indoors, especially during cold Midwest winters, I avoid it. The smell of hot metal lingers for hours. In humid areas, like the South, I always oil the base and pivot after use to stop rust.

The chop saw is best when:

- You need straight, repeated cuts on metal.

- You’re doing framing or fabrication where looks don’t matter.

- You want speed and strength, not fine detail.

When to Use a Miter Saw

I pull out my miter saw for clean and accurate cuts. It’s the tool I trust for trim, molding, or cabinetry — any project where the cut needs to look right the first time. When I built baseboards for a home in Ohio, my miter saw saved me hours of sanding and fitting.

It’s also great for angled or compound cuts, like crown molding or corner joints. I can fine-tune the angle by degrees for a perfect fit. Indoors, it’s quieter and cleaner than a chop saw, thanks to its soft-start motor and dust bag.

Cordless versions make outdoor work easier — perfect for decks or sheds without outlets. Just keep a spare battery handy in cold weather since batteries drain faster in freezing temps.

The miter saw is best when:

- You need accurate, angled cuts for wood or trim.

- You’re doing finish work, flooring, or cabinetry.

- You want a clean, quiet workspace with little mess.

Crossover Uses

Sometimes, the lines blur. I’ve used a miter saw to cut aluminum trim with a non-ferrous blade — it worked great with slow, steady passes. On the flip side, a chop saw can cut rough lumber in a pinch, but it burns the wood and leaves ugly edges.

Safety and Skill Level — Chop Saw vs Miter Saw

Both tools can be dangerous if used carelessly. I’ve seen beginners, including myself years ago, underestimate them. A little focus and respect go a long way toward safe, clean cuts.

Chop Saw Safety

A chop saw is simple but not forgiving. Sparks, debris, and heat are part of every cut. I always wear gloves, glasses, and hearing protection. I also clear the area of flammable items. One summer in an Arizona garage, sparks hit sawdust and started to smolder — a good reminder to always sweep first.

Before every job, I inspect the abrasive wheel for cracks. A damaged wheel can shatter at full speed. I keep a firm grip, never force the blade, and clamp the material tight. Chop saws work best on a sturdy bench with little vibration.

Miter Saw Safety

A miter saw feels safer, but that can make people careless. The blade spins fast and can kick back if the wood isn’t clamped. I’ve had narrow trim lift and jam when I didn’t secure it properly — a quick reminder to never rush a cut.

Always keep your hands clear of the blade’s path. The guards help, but awareness matters most. In small garages or workshops, wear goggles and hearing protection. Even soft wood can throw dust and chips. In cold weather, avoid loose sleeves or gloves that could catch.

For beginners, a miter saw is easier to learn. The blade follows a set path, so once you know how to set angles and use the fence, it becomes second nature.

Maintenance and Durability — Chop Saw vs Miter Saw

I’ve learned that how you care for your saw matters just as much as how you use it. With a little upkeep, both saws can last decades. My old chop saw is nearly 10 years old — still strong — because I give it a quick cleanup after every job.

Chop Saw Maintenance

A chop saw takes a beating, especially when cutting steel or rebar. After each use, I wipe it down to remove dust and metal grit. In humid areas like Florida or Louisiana, I add a light coat of oil on the base, pivot, and clamp to prevent rust. A quick wipe now saves hours later when parts start to seize up.

Before every job, I inspect the cutting wheel. If I see cracks, chips, or wobble, I replace it right away. A damaged wheel can break at full speed — and that’s dangerous. I also check the power cord and switch. Chop saws pull heavy current, so damaged cords can be a real hazard.

Lastly, I keep the motor vents clear. Dust builds up fast in garages and outdoor setups, especially in dry, dusty places like the Southwest. A few blasts of compressed air keep the motor cool and running smooth.

Miter Saw Maintenance

A miter saw needs more finesse. I treat mine like a precision tool, not a brute. The first rule — keep the blade sharp. A dull blade burns wood and strains the motor. I sharpen or replace it as soon as cuts start dragging or tearing.

I also check calibration every few months. Heavy use or transport can knock it off by a degree or two. A quick test cut keeps angles perfect. I learned that the hard way while trimming crown molding — even a small drift can ruin a corner.

After each project, I vacuum dust from the motor vents and table. Fine dust can jam bearings, especially in dry regions like Arizona. In coastal areas, I cover the saw or store it inside to stop rust on the rails and fence.

Finally, I inspect guards, clamps, and bolts. Loose hardware causes bad cuts and safety risks. It takes one minute to check, but it makes a big difference.

Durability Tips for Both

- Store indoors whenever possible. Avoid damp or unheated sheds.

- Cover tools with a breathable tarp to block dust and moisture.

- Replace worn parts early — wheels, brushes, and bearings are cheap and easy fixes.

Summary / Conclusion — Chop Saw vs Miter Saw

After years in the shop, here’s what I’ve learned: a chop saw and a miter saw aren’t competitors — they’re teammates. Each one does a different job, and trying to swap them only slows you down.

The chop saw is built for power and endurance. It cuts through metal, rebar, and framing with ease. It’s tough, loud, and made for sparks — not fine detail.

The miter saw is built for precision and control. It’s my choice for clean joints, smooth cuts, and professional finishes. It’s quieter, cleaner, and perfect for wood or trim work.

Knowing which saw to grab isn’t just about working faster — it’s about safety and results. The right tool keeps your work sharp and your hands safe.

In short:

- Chop saw = power and durability for metal.

- Miter saw = accuracy and finesse for wood.

Both are essential. The best shops have one of each — and know exactly when to use them.

FAQ — Chop Saw vs Miter Saw

Can I use a miter saw to cut metal?

Yes — but only for soft, non-ferrous metals like aluminum or brass. Use a non-ferrous metal cutting blade and cut slowly. I’ve done this for aluminum trim with great results. But never try to cut steel — that’s a job for a chop saw.

Is a chop saw good for wood?

Not really. A chop saw grinds instead of slicing, so it burns or splinters wood. If you’re cutting wood — even rough boards — a miter saw gives you cleaner, safer cuts.

Which is safer for beginners?

A miter saw. It’s easier to control and has guards that guide the blade. A chop saw throws sparks and needs more caution. If you’re new to cutting tools, start with a miter saw to build your confidence.

Do professionals use both tools?

Absolutely. Most pros have both in their setup. Metalworkers rely on chop saws for steel, while carpenters use miter saws for wood and trim. The best workspaces use each tool where it shines.