It was a cool week night. I was out in my back shop. I had a big stack of pine boards to cut. I like the fresh smell of cut pine wood. It makes the whole room smell so good. I put my first big board on the metal base.

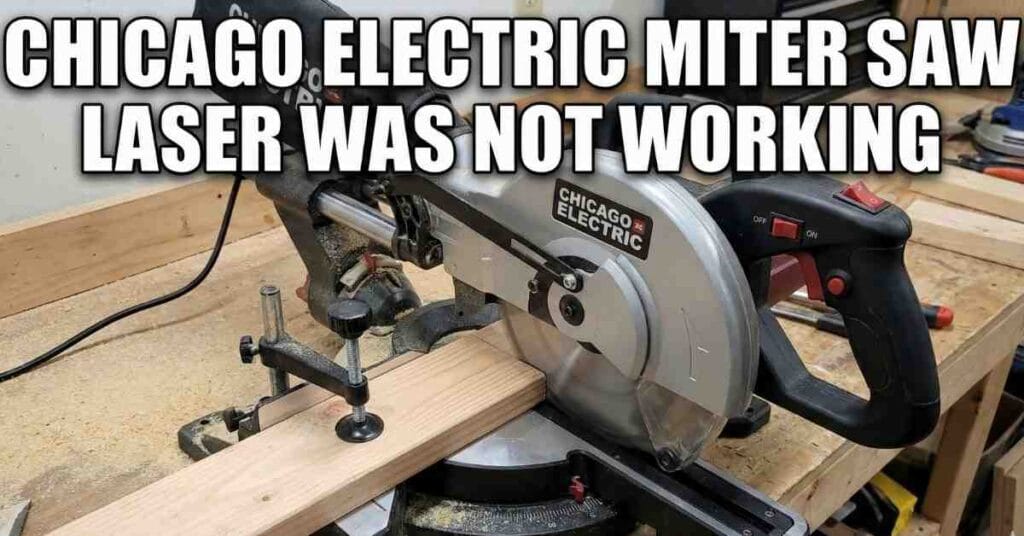

I reached for my big power tool. I flipped the red switch to the on side. I looked down at the dark wood piece. The bright red line was totally gone. My chicago electric miter saw laser was not working at all.

This made me feel very sad and stuck. I test tools all the time for my work. I know how much a good guide line helps. It keeps my blade paths straight and very true. I stood there and felt quite dumb.

I had to stop my hard work right then. I put my wood tape down on the desk. I knew I had to fix this right away. I took a deep breath of the cold air. I want to tell you how I fixed it fast.

Why A Tool Light Fails In The Shop

Power saws take a lot of hard use. They shake hard when the big blade spins. They also make a huge ton of fine dust. This dirt gets deep inside the small tool parts.

The red beam is a weak part of the tool. It can break down for a few main facts. I found four main causes in my own home shop. I want to share this clear data with you.

This clear list will save you a lot of time. You will know just what to look for first. Let us look at the cold hard facts now. It is best to know the whole true root cause.

Table 1: Quick Light Fix Guide

| Sign | Cause | Best Fix |

| No red light | Dead power cells | Put in fresh new cells |

| Weak light | Low cell power | Buy new cells soon |

| Light cuts out | Loose fit inside | Clean the metal bits |

The Hidden Power Source

Most guys think the wall plug powers the light. I thought that exact same thing for a long time. But that thought is very wrong in this case. The light runs on its own small power source.

It uses two small round coin cells to run. The small box hides right near the top hand grip. When they die, the light goes out very fast. It is a quick and cheap fix for you.

I felt a bit silly when I found this out. I had the tool plug in the wall all day. But the red beam still would not turn on. The wall power does not help the small light.

Fine Wood Dust On The Glass

Cutting thick wood makes a huge mess of dirt. This fine dirt floats all up in the cold shop air. It lands on all the hard parts of the saw. The light shines through a small clear glass hole.

Thick dirt blocks the red beam from coming out. You might see a very weak blur on the wood. You might see no red line shine at all. I found a thick coat of dirt on my glass.

The light source is right by the big blade. This means it gets hit with dirt all the time. It is the worst spot for a clear glass part. But that is how they build the tool.

A Stuck Red Switch

The small red switch turns the beam right on. Wood dust packs deep into its tight small gaps. The metal parts fail to touch inside the switch. Then the power stops right there in its tracks.

The switch might feel stiff or hard to push. It will not make a crisp and loud click sound. I had to push my switch super hard one day. That told me it was full of thick shop dirt.

A bad switch is a huge pain to use. It hurts your thumb to push it so hard. I knew I had to clean it out real well. Dirt is the main foe of all shop tools.

Shaking Pulls Wires Loose

The big saw motor shakes the whole tool hard. This heavy shake hurts the small thin cords inside. Thin cords run down to the red light tube. The shake can pull a soft wire right off.

A torn wire stops the power flow dead. The red beam will stay dark for good. You have to open the hard case to look. You can twist the bare wire back on quite fast.

I have seen this fault on a lot of tools. The wires are just too thin for a big saw. They snap off when the saw jumps in your hand. It is a very bad design flaw for sure.

Safe Steps For Your Shop Work

You must stay safe in your home wood shop. A saw is a very fast and sharp machine. You can get hurt if you rush the hard work. Always think first when you fix a power tool.

Pull the main plug from the wall first. Do not just turn the wall switch to off. Pull the thick cord right out with your bare hands. This stops all power to the big sharp blade.

Wear clear hard glasses on your face. You will blow loose dirt out of tight cracks. You do not want dirt in your two soft eyes. Safe eyes are key for a long life of work.

I put my clear glasses on right away. I took my thick work gloves off my hands. I need to feel the small parts with my bare skin. Now I was all set to start the fix.

Steps I Took To Fix The Red Beam

Now you know why the red light fails. Let us fix it deep in your own shop space. I got my small tools out right away. I made sure my tool had no wall power.

I went down a very simple step by step list. I started with the most simple fix first. You should do the same exact thing I did. Let us get your bright red line back today.

Step One: I Put In New Cells

Look near the top front hand grip. Find the small plastic square lid on top. It has one tiny screw holding it down tight. Take that small screw out fast and put it aside.

Pull the old dead cells out of the slot. Scrape the metal bits if they look green or bad. Put fresh new cells right in the clean box. Match the plus side the right way up.

I did this to my own saw first. I put the lid back on the small box. I flipped the red switch to the on side. The light was still dark on my wood board.

Step Two: I Wiped The Small Glass

Look down by the big metal blade guard. Find the small hole where the light shoots out. You will see a tiny glass piece set deep inside. Take a soft dry rag in your clean hand.

Rub the small glass very clean and clear. Do not use wet soap or spray at all. I wiped mine and dirt fell right off. It was a thick brown coat of pine dust.

I flipped the switch to check the bright line. It was still dark and dead in the shop. I knew I had to dig a bit deeper. The easy steps did not work for me.

Step Three: I Blew Air In The Switch

Push the switch back and forth very fast. Listen for a loud clear click noise. If it feels soft, dirt is packed deep in it. Grab a can of fast forced air to use.

Blow air right at the tight switch cracks. Push the button while you blow the fast air. I saw a huge cloud of dirt fly out. The switch clicked so much better right after that.

I tried the light one more time. Still no red beam hit the dark wood piece. I let out a long sigh of tired breath. I had to open the main case now.

Step Four: I Looked At The Tool Cords

This step takes a bit more slow calm work. Take out the screws on the main hand grip. Take off the hard plastic shell part. Look at all the thin cords tucked inside.

Track them from the box down to the tube. Find any cord that is torn off the metal. I found a tiny red cord loose inside my saw. The shake pulled it right off the main pin.

I stripped the soft end with my tool. I twisted the bare wire back on very tight. I put the hard plastic shell back on with care. I put all the screws back in their deep holes.

I flipped the red switch one last time. The bright red beam shone right on the wood. It was crisp and clear and very straight. I smiled big and felt so proud of my work.

How I Keep My Tool Safe Now

I hate when my good tools break down. I want my light to work all the time. I made a new firm rule for my shop. It saves me time and stops my high stress.

My Shop Care Steps

| Task | Time | Good Result |

| Blow dirt off | Each day | Switch stays crisp |

| Wipe glass off | Each week | Beam stays bright |

| Turn off switch | At night | Saves the cells |

My Fast Clean Up Rule

I clean up fast when my work is done. I suck up the big wood chips first. Then I blow air on the whole saw frame. I clean the small light parts best of all.

I check the red switch every single time. I make sure it is set to off. I left it on all night once in the past. It killed my fresh cells dead by the dawn.

I will not make that dumb mistake again. A clean tool is a very happy tool. It will serve you well for a long time. You just have to treat it right each day.

Final Words On This Good Saw

I really like this saw a whole lot. It cuts wood so straight and very true. It has very strong motor force for thick wood. The red beam is a nice small plus to have.

When my chicago electric miter saw laser was not working, it was bad. It made my work stop dead in its tracks. A dark beam is a big pain for sure. But the fix is quite quick and very cheap.

Do not throw your good tool in the trash. Just check the power and the dirt first. Then look for a loose cord in the case. You can get that red line back today.

You will learn more about your great tool. Take a deep breath and take your time. Then you can get back to your good work. I went back to cutting my pine boards fast.