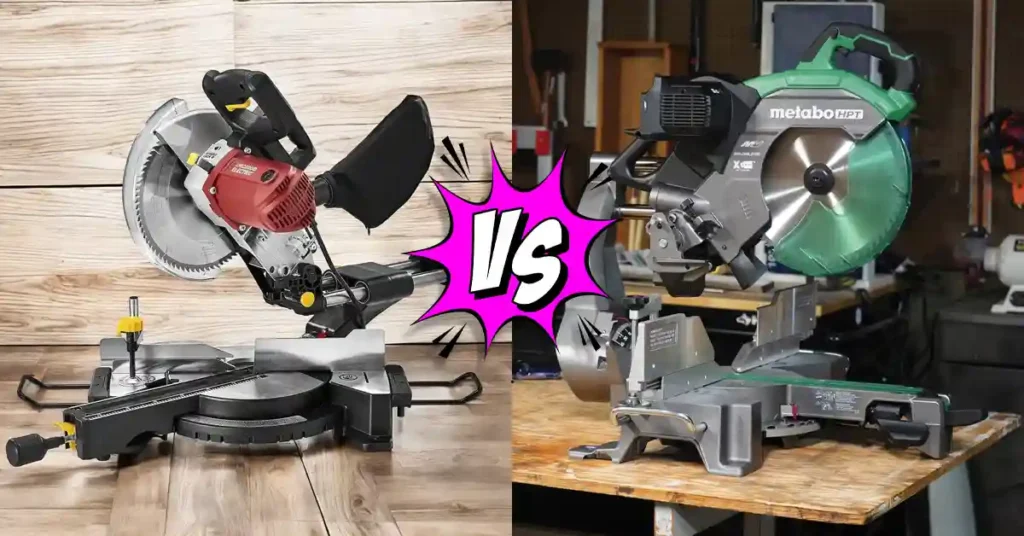

If you’ve ever stood in a hardware store trying to choose between a 10-inch or a 12-inch miter saw, you’re not alone. I’ve been there too — more times than I’d like to admit.

Over the years, I’ve used both for everything from tiny trim to rough framing. Each has its strengths. The right one depends on what you cut most.

I’ve tested them in all kinds of U.S. conditions — humid Florida garages, cold Midwest winters, and dry Arizona dust. Each taught me something new.

Here’s what I learned after years of cutting side by side.

Table of Contents

Understanding the Basics

Before comparing, let’s start simple. A miter saw cuts wood at set angles. You pull the blade down instead of pushing it forward, which keeps cuts straight and safe.

A 10-inch miter saw is compact and smooth. It’s perfect for trim, molding, or small furniture work.

A 12-inch miter saw is built for muscle. It handles big boards, beams, and framing lumber.

Both can crosscut, bevel, and miter with precision. The difference is how wide and thick they can go.

Technical and Practical Differences

Here’s what I’ve learned after owning both. My 10-inch Makita is light and sharp. My 12-inch DeWalt is a powerhouse.

Cutting Capacity and Power

This is the biggest gap. The 12-inch saw cuts through a 2×12 in one clean pass. The 10-inch stops around 2×8 or 2×10. If you frame decks or cut beams, the 12-inch saves time.

Precision and Control

The 10-inch wins for fine work. The smaller blade flexes less and spins faster. I get smoother edges with less tear-out. The 12-inch, while strong, can wander on tiny trim cuts if the blade is dull.

Portability and Ergonomics

The 10-inch is easier on the back. My DeWalt 12-inch weighs about 70 pounds. My Makita 10-inch is closer to 55. That’s a big deal when hauling tools up stairs or across a muddy yard.

Setup and Maintenance

Ten-inch blades are cheaper and everywhere — even small-town hardware stores carry them. Twelve-inch blades cost more and are harder to find. The smaller saw also needs less torque and setup time.

Safety and Learning Curve

Both are safe if used right. But the 12-inch has more kick and power. For beginners, the 10-inch feels steadier and easier to control, especially when learning compound angles.

Quick Comparison — 10-Inch vs 12-Inch Miter Saw

| Feature | 10-Inch Miter Saw | 12-Inch Miter Saw |

| Cutting Capacity | Cuts up to 2×10 | Cuts up to 2×14 |

| Precision | Smoother and tighter cuts | Can flex on small work |

| Power & Torque | Good for trim and light cuts | Best for thick boards |

| Portability | Easy to move and store | Heavy but stable |

| Blade Cost | Cheaper and easy to find | Pricier and limited |

| Ease of Setup | Simple and fast | Slower, needs space |

| Safety | Great for new users | Needs strong control |

| Best Use | Trim, molding, shop work | Decks, framing, beams |

When to Use Each Saw

I switch between them all the time.

When I’m cutting crown, door trim, or making picture frames, I grab the 10-inch. It’s light, smooth, and cuts sharp angles cleanly.

When I’m framing or cutting deck joists, I grab the 12-inch. It powers through 2×12 boards without a second cut.

Think of it like this: the 10-inch is for detail, and the 12-inch is for muscle.

Safety and Skill Level

Both saws are safe with care. Still, they feel different in hand.

The 10-inch is calm and predictable — great for beginners.

The 12-inch has torque. It bites deeper and needs a firm grip.

I always wear goggles, hearing protection, and a dust mask — especially in closed garages. In cold states, gloves help with grip when the metal gets chilly.

And always clamp your work. A steady board means a cleaner, safer cut.

Maintenance and Durability

A clean saw is a safe saw. No matter the size, maintenance makes all the difference.

Here’s what I do:

- Clean the rails and fence after each job. Dust buildup makes the saw drag.

- Check alignment often, especially after hauling it to a new site.

- Replace dull blades before they burn wood or tear fibers.

- Store smart. In humid states, I wipe the metal with oil. In cold garages, I keep a cover on to stop rust.

Take care of your saw, and it’ll stay square and smooth for years.

Summary

Both saws earn their keep.

The 10-inch shines for trim, furniture, and daily shop work.

The 12-inch rules when you need depth and strength for heavy cuts.

I use both, but my 10-inch handles most of my projects. The 12-inch comes out when lumber gets big.

It’s not about which one is better — it’s about what you cut most.

FAQs — About 10 vs 12 Miter Saws

What’s the main difference between a 10 vs 12 miter saw?

A 10-inch miter saw is lighter and easier to control. A 12-inch saw cuts thicker boards faster. Pick based on the size of wood you cut most.

Can a 10-inch miter saw cut a 4×4?

Yes, most sliding 10-inch saws can cut a 4×4 in one or two passes. Fixed models may need you to flip the board to finish the cut.

Which miter saw is better for home projects?

A 10-inch miter saw works great for trim, molding, and furniture work. It’s easy to move, affordable, and fits well in small home workshops.

When should I choose a 12-inch miter saw instead?

Go with a 12-inch miter saw for framing, decks, or large cuts. It gives you more power and reach for wide boards and heavy-duty jobs.

Do 10-inch and 12-inch miter saws use the same blades?

No. A 10-inch saw uses a smaller 5/8-inch arbor blade, while a 12-inch saw uses a 1-inch arbor. Always match blade size to your saw.