It was a cold Tuesday morning in my garage. I had a big project ready. I needed to shrink some plastic for a wiring job. I flipped the switch on my favorite heat gun. I saw the coils turn bright red. I smelled hot metal. But there was no sound. No air moved. My heat gun fan was not working.

I felt a pit in my stomach. Tools always seem to quit when you need them most. I knew if I kept it on, the plastic would melt. I shut it off fast. If you are here, you are likely in the same spot. Maybe you are stripping paint or fixing a phone. Either way, a heat gun with no fan is just a fire hazard.

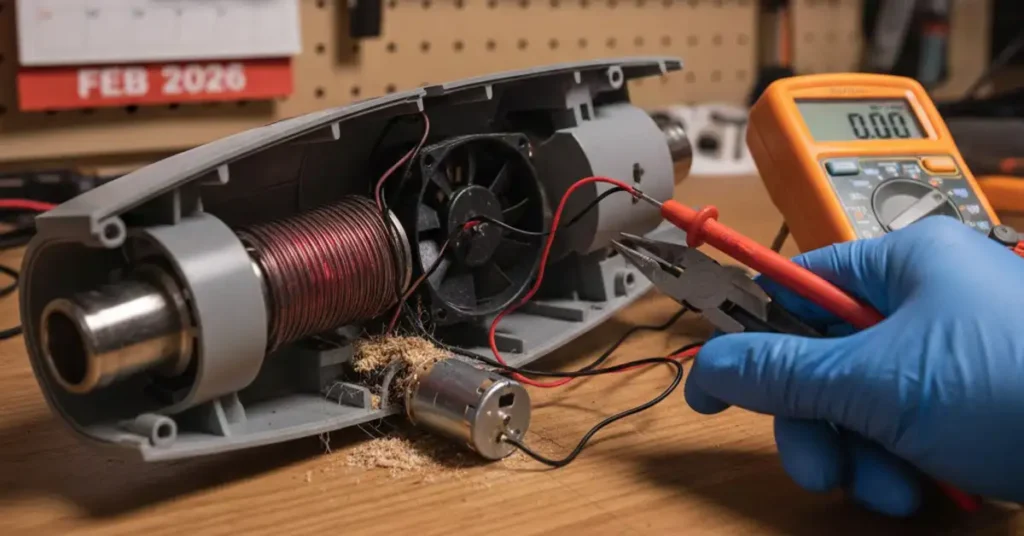

I spent the afternoon taking mine apart. I want to share what I found. I will show you how to check yours too. We will look at why these fans quit and how to get back to work. I love fixing my own gear. It saves money and feels good. Let us dive into the guts of this tool.

Common Reasons for Fan Failure

When a heat gun fan is not working, the cause is usually simple. These tools are tough, but they live in dusty places. I have opened many of them over the years. Most times, it comes down to a few key parts. You just need to know where to look.

Stuck Fan Blades

My garage is dusty. Sawdust gets everywhere. Your heat gun acts like a vacuum. It pulls air in from the back. If a piece of lint or hair gets in there, it can jam the blade. This is the most common issue I see.

I used a small pick to poke the fan through the vents. It did not move at all. That was my first clue. If the blade cannot spin, the motor will just hum. Eventually, that hum turns into a puff of smoke. Always check for dirt first.

Broken Wires

I drop my tools. A lot. Heat guns are built well, but they are not tanks. Inside the handle, there are very thin wires. One wire goes to the heater. One goes to the motor. If you bump the gun too hard, a solder joint can snap off.

I opened my casing. I saw a red wire hanging loose. It had vibrated off the motor terminal. This is a very common fix. It happens because the tool gets so hot and then cools down. This stress makes the metal weak over time.

| Part | Role | Common Sign of Failure |

| Fan Blade | Moves the air | Visible debris or no movement |

| DC Motor | Spins the fan | Screeching or grinding noise |

| Switch | Sends power | Gun stays totally dead |

| Wiring | Connects parts | Works only when you shake it |

How I Troubleshoot My Tools

I like to be smart about repairs. I do not just rip things apart. I follow a path. This saves time and keeps me from breaking more parts. Here is my personal checklist for any tool that stops working.

The Power Test

First, I check the cord. Sometimes the break is not in the gun. It is in the wire near the plug. I wiggle the cord while the gun is on for just a second. If the fan blips on and off, I know I need a new cord. This is a quick and easy test.

The Visual Inspection

I grab my flashlight. I shine it into the intake. I look for pet hair or wood chips. You would be shocked at what gets sucked in there. If I see a clog, I use compressed air. Sometimes a quick blast of air is all it takes to get the fan working again.

The Multimeter Check

If the fan is clear but still silent, I pull out my Fluke multimeter. I love this tool. It tells the truth. I check for “continuity.” This is just a way of asking if power can get from point A to point B. It is a vital tool for any shop.

I touch the probes to the motor wires. If the meter stays at zero, the motor is “open.” That means the wire inside the motor is burnt. If that happens, the tool is usually toast. It is better to know now than to waste an hour on a dead motor.

Repairs You Can Do at Home

You do not need to be an expert to fix a heat gun. You just need some patience. Most fans fail for reasons you can fix in twenty minutes. I have done this many times on my own bench.

Cleaning the Intake

This is the easiest fix. I do this once a month now. I use a soft brush to clean the plastic mesh. If the fan can breathe, it stays cool. If it stays cool, it lasts longer. A clean tool is a happy tool.

Soldering Loose Wires

If you find a loose wire, do not just tape it. It will get hot and fall off. You need a real fix. I use my soldering iron to melt a fresh dab of solder onto the motor tab. It takes just a minute to do it right.

I make sure the joint looks shiny. A dull joint is a weak joint. Once the wire is firm, I tuck it away from the heating element. You do not want wires touching the hot coils. That would cause a short circuit very fast.

Lubricating the Shaft

Sometimes the motor is just dry. I saw this on an old unit I found at a yard sale. The fan was stiff. I put one tiny drop of oil on the motor shaft. I spun it by hand for a minute to let it sink in.

When I plugged it in, it whirred to life. It sounded like new. Do not use too much oil. You do not want it dripping onto the heater. Just one drop is plenty for these small motors.

When to Give Up and Buy New

I hate throwing things away. But sometimes, a repair is a bad idea. A heat gun handles a lot of power. If the plastic inside is charred or melted, stop right there. It is not safe to use anymore.

If the heating element is broken and the fan is dead, the cost is too high. You can buy a new, safe gun for less than the price of parts. I keep my old ones for spare screws and cases. It is good to know when to let go.

| Repair Step | Difficulty | Tools Needed |

| Clear Debris | Very Easy | Toothpick or Air |

| Check Switch | Medium | Multimeter |

| Solder Wire | Medium | Soldering Iron |

| Replace Motor | Hard | Screwdriver & Parts |

My Final Thoughts on Tool Care

I learned my lesson that Tuesday morning. I now keep my workspace cleaner. I do not let my tools sit in the dust. A little care goes a long way. It keeps my gear running when I have a deadline.

If your heat gun fan is not working, do not panic. Take a breath. Look for the simple stuff first. Check the intake. Look for a loose wire. Most of the time, you can fix it yourself. You will save money and feel like a pro.

My heat gun is back in my bag now. It sounds strong and blows hot air. I finished my wiring job just in time for lunch. There is a great feeling in fixing something with your own hands. It makes the work more fun.

FAQs: Heat gun fan not working

Why is my heat gun getting hot but the fan is not spinning?

Your heating element is working, but the motor is stuck. This happens when hair or dust jams the blade. Turn it off now to prevent the plastic from melting or catching fire.

Can I fix a heat gun fan that stopped working?

Yes, you can often fix it by cleaning the intake vents. Check for loose wires inside the handle too. A quick solder job or a drop of oil on the motor shaft usually does the trick.

Is it safe to use a heat gun if the fan sounds slow?

No, a slow fan means the motor is failing or dirty. Reduced airflow causes the tool to overheat quickly. Clean the fan blades or check the motor before you use it for another big project.

What should I do if my Wagner heat gun smells like smoke?

Smoke usually means dust is burning or the motor is seizing up. Unplug the tool and look for clogs in the back. If the wires look charred inside, it is time to buy a new, safe unit.