I remember the first time I held a belt sander. It scared me a bit. I turned it on, and it jerked forward like a wild dog on a leash. It almost flew out of my hands. My heart raced, and I quickly let go of the trigger. It was loud, heavy, and very aggressive. I knew right then that this tool demanded respect.

But over the years, I have learned to love it. It is now my go-to tool for big, rough jobs. It saves me so much time and sweat. If you have a big deck to strip or a rough table to flatten, this is the tool you need. It does the hard work so you do not have to. I want to share what I have learned so you can use it safely.

Why I Choose the Belt Sander

I do not use this tool for everything. It is too strong for small, delicate items. If I used it on a small chair leg, it would eat the wood away. I grab it when I need to remove a lot of wood fast. It is a heavy lifter in my shop.

Think of it like a bulldozer. You use a bulldozer to clear a field. You do not use it to plant a flower. The belt sander is my bulldozer. It rips through old paint and varnish. It levels out glued boards that are not flat. It shapes wood faster than any other hand tool I own.

I own other sanders, like an orbital sander. That one is gentle and moves in circles. It is great for the final smooth finish. But the belt sander is for the start of the job. It does the heavy grinding. I always start with the belt and finish with the orbital. That is my secret to a good project.

Safety Gear Is Not Optional

I learned this the hard way. This machine creates a storm of dust and noise. The first time I used it, I did not wear a mask. I was coughing up dust for two days. My ears rang for hours. It was a mistake I never made again.

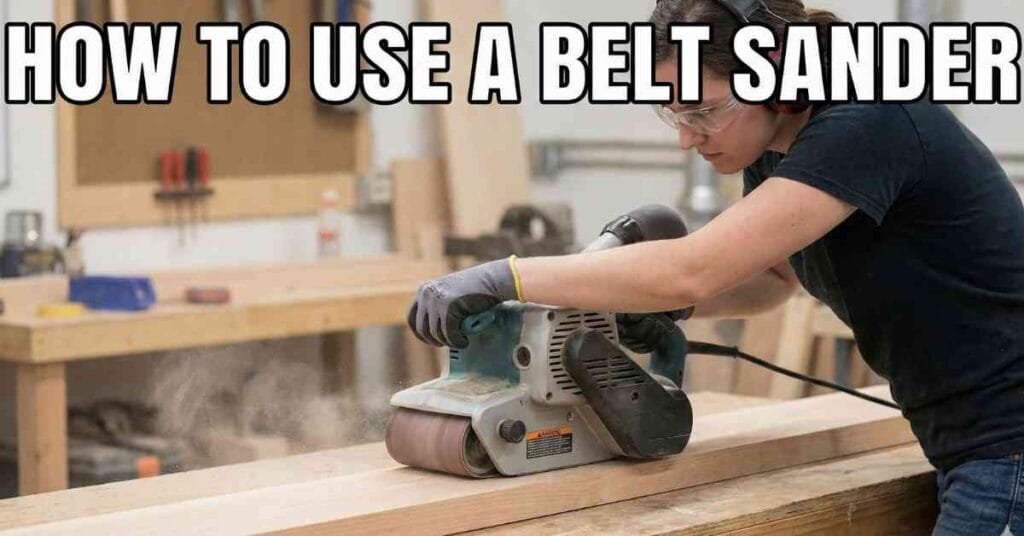

Now, I suit up before I even plug it in. I put on safety glasses to stop flying chips. I wear foam earplugs because the motor whine is high and piercing. Most importantly, I wear a good dust mask. The dust is very fine and hangs in the air. You do not want that in your lungs.

I also check my clothes. I tuck in my shirt. I roll up my sleeves. The belt moves very fast. If it grabs a loose sleeve, it will pull your arm into the sander. That is a nightmare scenario. I check my hair and strings on my hoodie too. I keep everything tight and out of the way.

Understanding the Sanding Belt

The belt is just a loop of sandpaper. But not all belts are the same. You have to pick the right one for the job. The “grit” number tells you how rough it is. A low number is rough. A high number is smooth.

If I have to strip old red paint off a floor, I use a 40 or 60 grit belt. It feels like rocks glued to paper. It cuts deep and fast. It leaves scratches, but it gets the paint off. If the wood is just a bit rough, I start with 80 grit. It is a good middle ground.

I rarely go above 120 grit on this machine. It is just not made for fine finishing. If I try to use a very fine belt, it gets hot and clogs up. I switch to my orbital sander for the smooth 220 grit finish. It does a better job at the end.

Types of Belts I Use

| Grit Number | Roughness | Best Use Case |

| 40 to 60 | Very Coarse | Stripping paint, varnish, or very rough wood. |

| 80 to 100 | Medium | Smoothing out saw marks and leveling boards. |

| 120 to 150 | Fine | Light sanding (I usually switch tools here). |

| Crepe Stick | Rubber | Not a belt, but used to clean the belts. |

How to Load the Belt Correctly

I messed this up once and snapped a brand new belt. I did not look at the arrows. Most sanding belts have a seam where they are glued. They are made to spin one way. If you run them backward, the seam hits the wood and breaks.

I look at the back of the belt first. There is a big arrow printed there. Then I look at the side of my sander. There is an arrow on the housing too. I make sure they point in the same direction. It is a small step, but it matters.

Changing the belt is easy on most tools. I pull a lever on the side. This releases the tension on the rollers. The old belt slides right off. I slide the new one on and center it. Then I snap the lever back down. The belt should feel tight.

The Tracking Knob Trick

This is the part that frustrates new users. You turn the sander on, and the belt flies off to the side. It rubs against the metal body. This heats up the metal and ruins the edge of the belt. You have to adjust it.

I flip the sander upside down on my bench. I hold it steady and pull the trigger. I lock the trigger so it stays on. Then I watch the belt spin. There is a small knob on the front or side. This is the tracking knob.

I turn the knob slowly. If I turn it one way, the belt moves left. If I turn it the other way, it moves right. I tweak it until the belt stays right in the middle of the rollers. I let it run for a few seconds to be sure. Once it runs straight, I am ready to sand.

My “Airplane Landing” Technique

This is the single most important tip I can give you. If you start the sander while it is resting on the wood, it will run away. It will also dig a deep hole right where you started. We call this a “gouge.” Gouges are very hard to sand out later.

I use a method I call the “airplane landing.” Think of a plane coming in to land. The wheels are spinning before they touch the ground. The plane is moving forward as it touches down. I do the same thing with my tool.

I hold the sander in the air above the wood. I pull the trigger and let the motor reach full speed. Then, I move my arms forward. As I move, I gently lower the sander onto the wood. It touches down smoothly. It does not jerk or dig. It just starts sanding as it glides.

When I am done with a pass, I do the opposite. It is like an airplane taking off. I lift the sander up while it is still moving forward. I only let go of the trigger once it is safe in the air. This stops me from making marks at the end of the board.

Going With the Grain

Wood is like a bundle of straws. The fibers run in one direction. We call this the grain. You can see the lines in the wood. You should always sand in the same direction as those lines. It makes the wood smooth.

If you sand across the lines, you tear the fibers. It leaves deep, ugly scratches. These scratches soak up stain and look dark later. It ruins the look of the project. I always check the grain direction before I start.

Sometimes the grain swirls around. This happens near knots. In those spots, I just do my best. I move the sander gently. I try to follow the main flow of the wood. But for straight boards, staying with the grain is a strict rule for me.

Do Not Push Down

This was a hard habit for me to break. I used to think that pushing harder made the work go faster. I would lean my body weight onto the tool. I thought I was helping. I was actually hurting the tool and the wood.

The belt sander is heavy for a reason. It has a big motor and a metal frame. That weight is enough to do the cutting. If you push down, you bog the motor. It slows down. The fan inside cannot cool it off. The motor gets hot and can burn out.

Pushing also creates too much heat on the wood. I have burned cherry wood by pushing too hard. It leaves dark black marks. Those are a pain to remove. Now, I just guide the sander. I hold it loose. I let it glide. My arms just steer it. The tool does the work.

Keeping the Belt Clean

Wood dust can clog the sandpaper. Pine is the worst for this. It has sticky sap. The dust mixes with sap and fills the grit. The belt feels smooth and stops cutting. It just rubs and gets hot. I used to throw these belts away.

Then I found out about the crepe stick. It looks like a big rubber eraser. It is cheap and lasts for years. It is the best accessory I own. It saves me so much money on belts.

To use it, I clamp the sander upside down. I turn it on. I press the rubber stick against the moving belt. You can see the dust fly off. The rubber grabs the gunk and pulls it out. The belt looks brand new in seconds. I clean my belt often, maybe every five minutes of sanding.

Dealing With Dust

The dust bag that comes with the sander is okay. It catches some of the big stuff. But a lot of fine dust still escapes. It covers my hair, my bench, and my other tools. It gets everywhere.

If I am working inside, I hook up a vacuum. I have a shop vac with a long hose. I use a rubber adapter to plug it into the sander. This captures almost all the dust. The air stays clean. I can breathe easier.

The hose can be annoying though. It drags behind the sander. It can get caught on the edge of the bench. I sometimes throw the hose over my shoulder. This keeps it out of the way. It is a bit awkward, but it is worth it for the clean air.

Sanding Vertical Surfaces

Sometimes I have to sand a door frame or a post. The surface is vertical. Gravity does not help me here. The sander feels much heavier. My arms get tired very fast.

I plant my feet wide. I hold the sander tight with both hands. I make short passes. I do not try to do the whole thing at once. I take breaks to rest my arms. If I get tired, my hands slip. That is when I make mistakes.

I also watch out for my face. The sander is closer to my head in this position. The dust falls down right onto me. I make sure my goggles are tight. I make sure my mask fits well. I take extra care to be safe.

Buying Advice from My Experience

I started with a cheap plastic sander. It cost me fifty dollars. It screamed loud and got hot fast. The tracking knob never worked right. The belt was always slipping. It was a pain to use.

Eventually, I bought a better one. It cost more, but it was worth it. It is heavier and made of metal. The motor is quiet and smooth. The belt stays straight. If you plan to do a lot of work, buy a good one. It will last you a lifetime.

Size matters too. The most common size is 3×21 inches. This is a good all-around size. My first one was 3×18, which is smaller and lighter. It is good for small hands. The big 4×24 sanders are beasts. They are for pros who sand floors all day. I stick to the 3×21. It fits my projects best.

Common Problems and Fixes

I have run into many issues over the years. Here is what I do when things go wrong. If the sander smells like burning plastic, I stop. I am usually pushing too hard. Or the belt is totally worn out. I check the belt first.

If the sander creates ripples in the wood, I am vibrating too much. This happens if I hold it too loose. Or maybe the belt has a bump in the seam. I try a new belt. I also try to walk steadily. I do not stop and start.

If the belt snaps a lot, the rollers might be worn. The rubber on the rollers can get old and cracked. If the rollers are not flat, the belt wobbles. I had to replace a roller on my old sander once. It was an easy fix.

Final Thoughts

Using a belt sander is a skill. It takes practice. Do not rush it. Grab a piece of scrap wood first. Practice the airplane landing. Practice adjusting the knob. Get a feel for the power.

Once you master it, it is a joy to use. You can take a rough, ugly board and make it clean. You can strip a whole deck in a weekend. It gives you power over the wood.

Just remember the rules. Wear your gear. Do not push down. Keep it moving. If you do that, you will get great results. The tool will last, and your projects will look great. Be safe and have fun making dust.

FAQs – How to Use a Belt Sander

What is a belt sander best used for?

A belt sander is the best tool to strip paint or level rough wood. It cuts very fast, acting like a dozer for big tasks like sanding a large deck or wood floor.

Can I use a belt sander for fine finishing?

No, a belt sander is too rough for a fine finish on wood. It leaves scratches, so swap to an orbital sander to smooth the surface before you apply dark stain.

How do I stop the belt from slipping off?

Fix this by turning the tracking knob while the sander runs. Adjust it slowly until the sanding belt stays centered on the rollers to prevent heat and damage.

Why does my belt sander gouge the wood?

Gouges happen if you start the sander while it touches the wood. Start the motor in the air, then lower it gently while moving forward to avoid nasty, deep marks.

Do I need to clean my sanding belt?

Yes, clean belts cut better and last much longer. Use a rubber crepe stick against the running belt to remove clogged wood dust and sticky sap in a few seconds.