It was a Tuesday night in my garage. I was turning a maple bowl. I went for a final pass. I wanted a smooth finish.

Suddenly, BANG.

A nasty catch tore a chunk out of the rim. I shut off the lathe. My hands shook a little. I looked at my tool. It was dull.

I had forced the cut. That is dangerous.

If you fight the wood, you are doing it wrong. You need to learn how to sharpen lathe chisels. It makes turning fun, not scary.

Here is how to get a scary-sharp edge.

The Grinding Setup You Need

I used to use an old grinder. It was fast and loud. It burned my tools. That was a mistake.

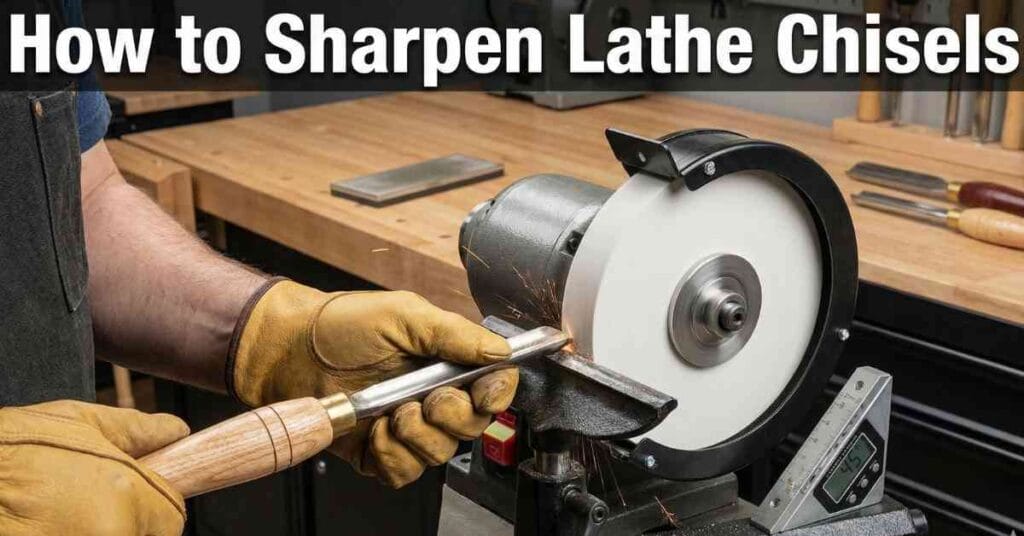

You don’t need rich tools. You need the right tools.

Bench Grinder Basics

Most grinders are too fast. They run at 3450 RPM. This heats up the metal. It ruins the temper.

You want a slow-speed grinder. Look for one that runs at 1725 RPM. It is gentle on the steel.

Next, check the wheels.

- Grey Wheels: These come in the box. Throw them away. They are too rough.

- White Wheels: These are good. They grind cool. They wear down fast though.

- CBN Wheels: These are the best. They are made of steel. They never change shape.

Here is a quick look at your options:

| Wheel Type | Cost | Heat | Maintenance |

| Grey Stone | Low | High (Bad) | A lot |

| White Stone | Medium | Medium | Some |

| CBN Wheel | High | Low (Best) | None |

Why You Need a Jig

Freehand grinding is hard. I tried it. My edges were round and dull.

Buy a jig system. The Wolverine system is a great choice. It holds the tool steady. It sets the angle for you. It fixes your mistakes.

Safety Note: Wear safety glasses. Dust masks are smart too. Metal dust tastes bad.

The “Sharpie Trick” for Perfect Angles

This is my favorite trick. It saves your steel. It is easy to do.

Grab a black Sharpie marker. Color the bevel of your tool. The bevel is the slanted part.

Adjusting the Jig

- Keep the grinder OFF.

- Put the tool in the jig arm.

- Touch the colored bevel to the stone.

- Spin the wheel with your hand.

Look at the ink.

- Ink gone at the top? The arm is too close.

- Ink gone at the bottom? The arm is too far back.

- Ink gone in the middle? You are perfect. Lock it tight.

This ensures you only grind what you need.

How to Sharpen a Bowl Gouge

The bowl gouge is a key tool. But the shape is odd. It looks like a fingernail. This makes it hard to grind.

Setting the Arm

Put the handle in the V-pocket of the jig. You must set the depth. This is how far the metal sticks out.

Most jigs need 2 inches. I drilled a hole in a wood block. The hole is exactly 2 inches deep. I use it to check my tool. It is fast and easy.

The Swing

Turn on the grinder. Wait for the hum.

Touch the tool to the wheel. Do not push hard. Let the wheel work.

Roll the tool side to side. Swing it like a dance. Keep it moving. If you stop, you ruin the edge.

Check the Tip: Watch for sparks. You want sparks to fly over the top edge. That means the tip is sharp.

Sharpening Scrapers and Parting Tools

These tools are simple. They are easier than gouges.

The Scraper

Scrapers do not slice. They scrape. You want a rough edge. This is called a “burr.”

- Set the flat table on your grinder.

- Lay the scraper flat.

- Push it gently into the wheel.

- Feel the top edge. Be careful! If it feels rough, you have a burr. That burr cuts the wood.

The Parting Tool

You use this to cut wood off the lathe.

- Lay it flat on the table.

- Grind until you see sparks.

- Flip it over. Do the other side.

- Keep the point in the center.

Honing: The Final Polish

Sometimes, you can skip the grinder.

Last week, my chisel felt sticky. It was not cutting well. I did not grind it.

I used a diamond card. It is the size of a credit card.

I rubbed it on the flat side of the bevel. I did this three times. It took ten seconds. The tool was sharp again. This makes your tools last longer.

Common Mistakes

I have made these mistakes. You might too.

Blue Steel

Did the tip turn blue? It got too hot. The metal is soft now. It will not hold an edge.

- The Fix: Grind past the blue part. Go slow next time. Use water to cool it down.

Changing the Angle

Do not change the angle of a new tool. Stick to the factory shape. Learn to use it first. Then you can change it later.

Conclusion

Sharpening is not a chore. It is part of the fun.

A sharp tool makes a quiet hiss. It cuts clean. It feels safe.

Go check your tools. Run your thumb lightly over the edge. Is it dull? Go to the grinder.

FAQs – How to Sharpen Lathe Chisels

How often should I sharpen lathe chisels?

Sharpen lathe chisels often. If you see dust, stop. Go to the grinder. A sharp tool cuts clean. It is safer to use. Do not force a dull edge. Keep the edge keen.

What is the best grinder for lathe tools?

Get a slow speed bench grinder. It runs at 1725 RPM. This keeps steel cool. Fast speeds burn the metal. Use white wheels or CBN wheels to get a truly sharp edge.

Can I sharpen lathe tools without a jig?

You can, but it is hard. A jig holds the tool steady. It keeps the angle right. Freehand grinding takes skill. Most pros use a jig to save time and save steel.

Why does my chisel turn blue when grinding?

The steel got too hot. You pushed too hard. The metal is now soft. You must grind past the blue spot. Use a light touch next time. Dip the tool in water to cool it.

Do I need to hone my turning tools?

Honing helps a lot. Use a diamond card on the edge. It makes the sharp edge last longer. You can skip the grinder. Rub the card on the bevel for a keen cut.