I still remember the first time I tried to solder aluminum. It was a Saturday afternoon, and I was trying to fix a bracket on an old RC car. I grabbed my trusty soldering iron, some standard tin-lead solder, and went to town.

It was a disaster. The solder just balled up and rolled off the metal like water on a duck’s back. I sat there confused, staring at a mess of grey blobs on my workbench.

Here is what I’ve learned about soldering aluminum, from the frustrations to the techniques that actually stick.

Table of Contents

Why Soldering Aluminum is So Hard

For years, I thought my iron just wasn’t hot enough. It turns out, heat wasn’t the main enemy. The real villain is chemistry.

Aluminum has a secret defense mechanism. The moment bare aluminum touches air, it forms a tough “skin” called aluminum oxide. You can’t see it, but it’s there.

This oxide layer melts at a much higher temperature than the metal itself. So, when you try soldering to aluminum with regular gear, you are just melting solder on top of that dirty skin. It never actually touches the metal underneath.

To make it work, you have to break that skin.

The Gear You Actually Need

When I finally got this right, it wasn’t because I bought a thousand-dollar machine. I just changed my consumables.

What you really want is a low-temperature aluminum rod (often zinc-based) or a specific solder made for this job.

Here is my go-to list:

- A dedicated flux: You need a flux specifically labeled for aluminum. It smells strong, but it eats through that oxide layer.

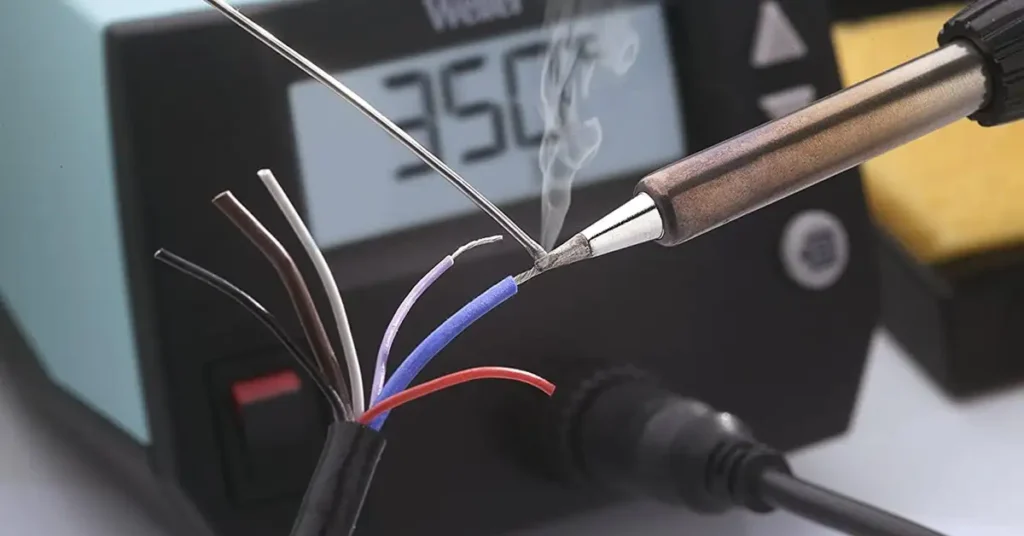

- A hotter heat source: Aluminum sucks heat away fast. For small wires, a high-wattage iron works. For bigger parts, I use a MAP-pro gas torch.

- Stainless steel brush: Use a brand new one. Do not use the one you used on rusty steel last week, or you will contaminate the joint.

How to Solder Aluminum to Aluminum

The process feels a bit different than standard electronics work. It feels more like plumbing.

Clean it like crazy. I scrub the metal with a stainless steel brush until it is shiny. Then, I wipe it down with acetone. You have to be quick here because that oxide layer starts forming again immediately.

Apply the specialized flux. I add the flux right away. This seals the metal and stops the air from getting to it.

Heat the metal, not the solder. This is where I messed up early on. I heat the aluminum part itself. I touch the solder to the metal every few seconds. When the metal is hot enough, the solder will melt on contact.

Watch the flow. If can you solder aluminum to aluminum is your goal, watch for the “wetting” action. The solder should spread out flat, not sit in a ball. If it balls up, you have to stop, cool it, and clean it again.

The Challenge: Soldering Aluminum to Copper

This is a common headache, especially for anyone dealing with older HVAC units or odd electrical repairs. Soldering aluminum to copper is tricky because these two metals hate each other.

They cause “galvanic corrosion.” Basically, if moisture gets in the joint, the aluminum will eat itself away over time.

So, can you solder aluminum to copper? Yes, but I cheat a little. I use a special Al-Cu solder. I also make sure to tin (coat) the copper wire first, and then tin the aluminum separately before joining them.

Once they are joined, I always seal the connection with high-quality heat shrink tubing. This keeps the moisture out and stops that corrosion from starting.

A Serious Warning on Soldering Aluminum Wire

I need to pause for a serious safety note, specifically for my friends here in the USA.

If you live in a home built in the late 60s or early 70s, you might have aluminum branch wiring in your walls. Do not try soldering aluminum wire for household outlets or switches.

Household wiring expands and contracts with the heat of the current. Solder is rigid. Over time, a soldered joint in your wall can crack, arc, and start a fire. It is not up to code in most US states for a reason.

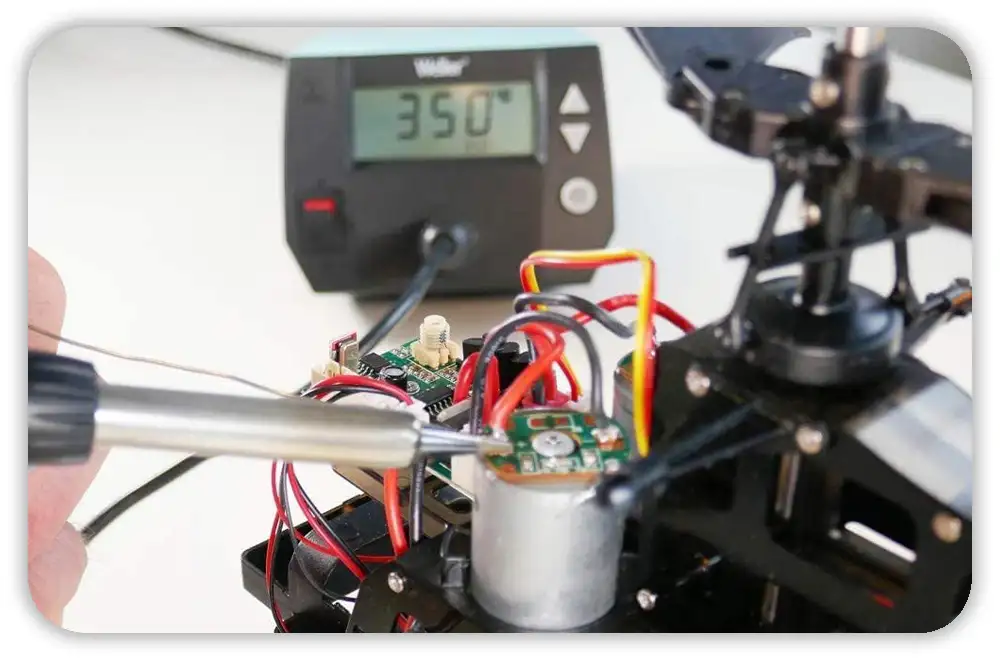

However, for things like drone batteries, RC cars, or speaker wire? Solder away. Just make sure you use that special flux I mentioned, or the wire will just turn black and brittle.

My Final Thoughts

So, can you solder aluminum? Absolutely. It just takes a little more patience and the right chemistry.

Don’t let the first few failed attempts discourage you. Once you see that solder finally flow smooth and shiny onto the aluminum, it is incredibly satisfying.

Just remember: Clean it, flux it, and respect the heat.

FAQs – Can You Solder Aluminum

Can you solder aluminum?

Yes, you can solder aluminum with the right gear. You need a special flux and strong heat. Regular solder will not stick to the metal skin at all, so buy a kit.

Can you solder aluminum to copper?

Yes, you can solder aluminum to copper. You need a special solder paste for this job. It stops the two metals from failing and keeps the joint safe and strong.

Do I need special flux for soldering aluminum?

Yes, you need flux made just for aluminum. It breaks the tough skin on the metal. Without this special flux, your solder will not stick and will just fall off.

Is soldering aluminum wire safe?

Soldering aluminum wire is fine for toys. Do not use it for house wiring. It can get too hot and start a fire. You need to use safe wire nuts for your safety.

Can I use regular solder on aluminum?

No, regular solder will not work. It cannot bond to the hard metal skin. You need a kit that is made for aluminum repair work so the joint holds really strong.