On a busy job site, the right tool can save time and keep you safe. I have used drills and impact drivers in hot sun and in deep cold. Each tool feels a bit different in each place. If you want to learn how to use an impact driver, I can help. I will share what I do to get fast work, real power, and good control.

This quick guide gives clear steps. It also gives simple tips and notes from real use.

Table of Contents

What Is an Impact Driver and Why Should You Use One?

An impact driver uses fast hits to turn screws with more force and less strain. It feels unlike a drill. When a screw starts to fight back, the tool gives quick bursts of torque. These bursts help with long screws and hard wood. A drill may stall in these spots, but an impact driver keeps the screw moving. The key point is that an impact driver makes tough jobs feel light.

I still recall the first time I used one. I was fixing a small deck at my home. My drill kept stalling in the thick boards. The impact driver slid the screws in with ease. That one job showed me how the tool works. It also showed me why it feels so strong. The key point is that it cuts work and stress at the same time.

How Does an Impact Driver Work?

When people ask how it works, I keep it simple. It spins like a drill. But when the screw gets tight, it adds small hits. These hits give short bursts of torque. The bursts help the bit dig in and stay straight. They also save your wrist and your time. Inside, a small hammer and anvil make this motion. The key point is that the hits add power when you need it.

Impact Driver vs. Drill — What’s the Difference?

I use both tools, and they feel different right away. A drill has a round chuck that grips smooth bits. An impact driver has a 1/4-inch hex collet. The collet takes quick-change bits with one push. The torque is much higher in an impact driver. It drives long screws fast and clean. I see this each time I switch from pre-drill work to screw work on my Milwaukee, DeWalt, or Craftsman tools.

A drill is best for light, neat tasks. An impact driver is best for dense wood or long screws. The key point is that both tools have a place, but the impact driver is the power tool for heavy jobs.

When Should You Use an Impact Driver Instead of a Drill?

I reach for an impact driver when a job feels hard or slow with a drill. Deck work is a clear case. Long deck screws sink with less push and less slip. Lag screws and frame screws act the same. Fence work, shed work, and frame work all feel smooth with impacts.

I also use one on small auto jobs. It helps with plate screws, trim screws, and tight spots under a car. In cold weather, metal threads get stiff. The impact helps break that stick with less strain. The key point is that an impact driver helps when a drill starts to fight back.

What Tools and Accessories Do You Need Before You Start?

You need a few key items to get the most from your impact driver. Good bits and simple safety gear make the tool safe and smooth.

Before I teach someone how to use an impact driver, I check the gear. Impacts hit hard. Weak bits can break and send chips out. Good gear keeps you safe and steady. The key point is that setup matters more than new users think.

Essential Bits for Impact Drivers

Use impact-rated bits only. They take the hits without cracks. The 1/4-inch hex shank fits the collet with one quick push. For most deck work, I keep T20 and T25 star bits. They grip well and do not strip easy. Nut drivers and socket bits help with small bolts. The key point is that good bits prevent slips.

Safety Gear You Should Use

I never skip eye gear. ANSI Z87.1 glasses keep chips out. Impacts can be loud, so ear gear is smart too. In winter, thin gloves help when I work in the cold. They add grip and keep my hands warm. The key point is that simple gear keeps you safe.

Helpful Add-Ons for Better Control

Small add-ons help more than most expect. A magnet bit holder keeps bits steady when I work on a ladder. A bit sleeve helps when I drive screws near trim. A belt clip helps on hot days when I move fast. A flex shaft lets me reach odd spots. The key point is that small add-ons make the tool easy to use.

How Do You Set Up an Impact Driver the Right Way?

Short summary: Setup is fast. Load the bit, check the power, pick a mode, and match the screw to the job. A clean setup makes the job smooth.

When I teach someone how to use an impact driver, I start with setup. It takes a few seconds. But these seconds shape how well the tool works. The key point is that prep stops most mistakes.

How to Insert and Remove Bits (Step-by-Step)

Hold the collet. Pull it out. Push in the bit. Let go and wait for the click. That click means the bit is locked. If it shakes, pull it out and try again. Dirt in the collet can cause shake. A quick tap clears it. The key point is that a firm click means a safe bit.

How to Choose the Right Speed/Mode

Most impact drivers have two or three speeds. Low speed helps with soft wood. High speed helps with long or hard screws. Some tools have a “soft” mode for small tasks. I use that mode for trim work or small parts. The key point is that the right speed gives control.

How to Select the Right Screw Type for Your Job

Pick screws that match the job. Wood screws for soft boards. Frame screws for big builds. Sheet metal screws for thin steel. If the wood is dense, drill a small pilot hole. This keeps the screw straight. It also stops splits. The key point is that the right screw makes the work smooth.

How Do You Use an Impact Driver Safely and Effectively?

This is how I use an impact driver on real jobs. These steps come from years of work in heat, cold, and tight spots. The key point is that simple habits make the tool safe and smooth.

Step-by-Step: How to Drive a Screw With an Impact Driver

I start with grip. I hold the driver with both hands. One hand stays on the handle. The other steadies the front. This keeps the bit straight and stops small slips. The key point is that two hands give more control.

Next, I square the bit to the screw. I learned this on old fence boards. If the bit sits at an angle, the screw strips fast. A straight start keeps the screw clean. The key point is that a square start saves the head.

Then I start slow. A soft pull on the trigger helps the bit bite. When the bit seats, the impacts take over. The tool pulses and sinks the screw with little push from me. The key point is that slow starts lead to smooth drives.

When the screw sits flush, I stop. One extra tap can bury the screw. This shows up a lot in soft pine used in many U.S. decks. The key point is that early stops protect the surface.

How to Keep the Bit From Slipping

Bit slips were my first big problem. The fix was simple. I keep light forward pressure. Even a small push keeps the bit in the screw. The key point is that steady pressure stops slips.

Fresh bits help too. Dull bits skate and skip. I see this most on deck screws in dry summer heat. A sharp bit locks in fast. The key point is that fresh bits save time.

Soft deck screws strip fast. Cheap screws bend and tear if speed is too high. I slow down and let the hits work. The key point is that slow impacts protect soft screws.

How to Control Torque Without Stripping Screws

Torque control takes time to learn. I feather the trigger when I work near trim. Short pulls stop the screw from diving deep. The key point is that light trigger pulls add control.

Low-speed modes help a lot. Most impact drivers have two or three. I use low mode for thin boards or small parts. Low speed gives me time to react when the screw seats. The key point is that low speed means more control.

Sometimes I switch to a drill. A drill has a clutch. The clutch helps with hinges and thin metal. The key point is that drills still have a place in fine work.

What Common Mistakes Should You Avoid?

I made many small mistakes when I first used an impact driver. These are the ones I see most in new users. The key point is that avoiding them saves time and stress.

Using Non-Impact Bits

I broke many bits before I learned better. Standard bits are not made for hits. They crack under impact force. When they break, they can strip the screw or fly out. The key point is that only impact bits can handle the hits.

Wrong bits also strip screws fast. The bit skips and scars the head. Now I check the bit rating before I start. The key point is that the right bit gives clean work.

Starting Too Fast

A fast start makes the bit wander. It can leave marks on the wood. I did this on a door frame once. I had to sand the mark out. The key point is that slow starts keep the wood clean.

Soft woods dent fast. Pine and cedar used in many U.S. homes show dents with too much speed. The key point is that slow speed protects the wood.

Holding the Driver at an Angle

If the tool tilts, the bit slips out. This is called cam-out. It ruins screws. I used to tilt the tool when I got tired. Holding it straight fixed the issue. The key point is that straight alignment stops cam-out.

Angle work also twists your wrist if the bit slips free. The key point is that a square stance is safer.

How Do You Remove Stuck Screws With an Impact Driver?

Stuck screws show up on old decks, cars, and steel brackets. An impact driver can free them with less strain. The key point is that impact force breaks stuck bonds better than a drill.

Best Bits for Removing Stripped Screws

For stripped screws, I use impact-rated extractors. They bite into the damaged head. Normal bits slip, but extractors grip tight. The key point is that extractors grab screws that other bits cannot.

Steel and stainless screws behave in different ways. Stainless can seize and gall. I go slow to keep heat down. Steel screws break loose with a few hits. The key point is that screw type shapes your method.

Using Penetrating Oil and Tapping the Bit

Penetrating oil helps a lot. I use PB Blaster or WD-40 for rusty outdoor screws. I let it soak a few minutes. Then I tap the bit with the driver. The small shakes help break rust. The key point is that oil and impacts work well together.

Short bursts work better than long pulls. The quick hits shake the screw loose. They keep the head safe from more damage. The key point is that gentle impacts do more than force.

Are There Torque Settings on an Impact Driver?

Impact drivers do not use a clutch like a drill. They use speed modes, presets, and your trigger pull. Many U.S. brands like DeWalt, Milwaukee, and Makita add smart modes for tough screws and soft wood. The key point is that torque comes from modes, not a clutch.

Electronic Modes (DeWalt, Milwaukee, Makita)

The first time I used modes the right way, I saw a big change. Each mode shifts how the tool acts. Each mode slows or speeds the hits. The key point is that the mode guides the torque.

Precision mode: I use this for shelves and trim. It slows the first hits so the screw does not dive. This helps with soft pine and MDF used in many U.S. homes. The key point is that precision mode stops fast drops.

Self-tapping screw mode: This mode helps with thin metal. My Makita holds a steady speed so the bit does not jump. This is great for plate screws and small metal brackets. The key point is that this mode keeps thin steel safe.

Low / medium / high impact: My Milwaukee M18 Fuel has these steps. Low is for soft woods. Medium is for most deck screws. High is for long structural screws. The key point is that speed steps give fast torque control.

How to Know When to Switch to a Drill With a Clutch

I switch to a drill when I need fine control. A drill has a clutch. The clutch gives a soft stop. This helps with cabinets and hinges. The key point is that a drill gives gentle torque.

Soft woods also need low force. Cedar and spruce dent fast. A drill keeps the screw from sinking deep. The key point is that weak wood needs a clutch.

Thin metal is the same. A drill stops before the screw tears through. I learned this on sheet metal vents in my garage. The key point is that thin steel needs more feel than force.

What Projects Are Perfect for an Impact Driver?

Impact drivers shine on jobs that need speed and power. They make home work, car work, and shop work much easier. The key point is that impact force saves time and strain.

DIY and Home Projects

I use my impact driver for most house jobs. Deck screws sink fast even in dense treated lumber used in the U.S. South and Midwest. The key point is that impacts make long screws simple.

Fence pickets come off clean. Old screws break loose with less wrist strain. The key point is that impacts free stuck screws well.

Shelves go up smooth. Drywall anchors seat with less slip. The key point is that control helps in tight spots.

Weather plays a role too. In humid heat, screws swell in wood. In cold, metal threads get tight. The impact driver breaks that drag. The key point is that impacts beat weather-based friction.

Automotive and Light Mechanical Jobs

I use an impact driver for small car work. Plate screws back out fast even when rusty. The key point is that hits break rust.

Interior screws come out clean. Short pulses protect thin plastic parts. The key point is that soft hits save trims.

With a nut driver, the tool acts like a small wrench. The key point is that socket adapters add speed.

Workshop and Garage Jobs

In the shop, the impact driver helps with builds. Workbench frames use long screws, and they drive in fast. The key point is that impacts help with thick joints.

Storage racks need solid holds. Lag screws bite into studs with no stalls. The key point is that impacts keep studs safe from slips.

Plywood builds feel smooth too. The bit stays straight even when the sheet moves. The key point is that steady torque helps with big panels.

How Do You Maintain and Care for Your Impact Driver?

A few habits keep an impact driver strong for years. Good battery care, light cleaning, and bit checks help a lot. The key point is that small steps stop big problems.

Battery Care Tips

U.S. seasons hit lithium packs hard. I never leave my packs in a cold garage in winter. Cold cuts power fast. The key point is that cold drains packs.

For long storage, I charge to about half. Full or empty storage hurts the cells. The key point is that mid-charge helps life.

Heat is bad too. In states like Arizona or Florida, packs die fast in hot shops. I store them inside. The key point is that heat kills batteries.

Cleaning and Lubrication Basics

I brush dust out of the vents after big jobs. Dust makes the tool run hot. The key point is that clean vents keep the motor cool.

A tiny drop of oil on the bit shank stops squeaks. It also keeps the collet smooth in dry climates. The key point is that light oil keeps things steady.

If the collet feels sticky, I tap it and clear dirt. The key point is that a clean collet gives a firm grip.

When to Replace Bits and Accessories

Bits wear down fast. I check them after deck work. Dull bits slip and tear screw heads. The key point is that sharp bits give clean drives.

Nut drivers and adapters wear too. Loose ones shake and wobble. I swap them when they feel soft. The key point is that tight tools give clean power.

If a bit turns blue or burns, I toss it. Heat means weak steel. The key point is that hot bits fail fast.

What Impact Driver Brands Do Most U.S. DIYers Use?

I have used many brands in heat, cold, and tight spaces. A few stand out for power, feel, and grip. Each one has its own style. The key point is that most U.S. DIYers pick a brand that fits their work and their budget.

Milwaukee

I use my Milwaukee M18 Fuel when I need raw force. It feels firm and smooth on big jobs. Deck work in hot Midwest summers feels much easier with it. The tool keeps its speed even in dense wood.

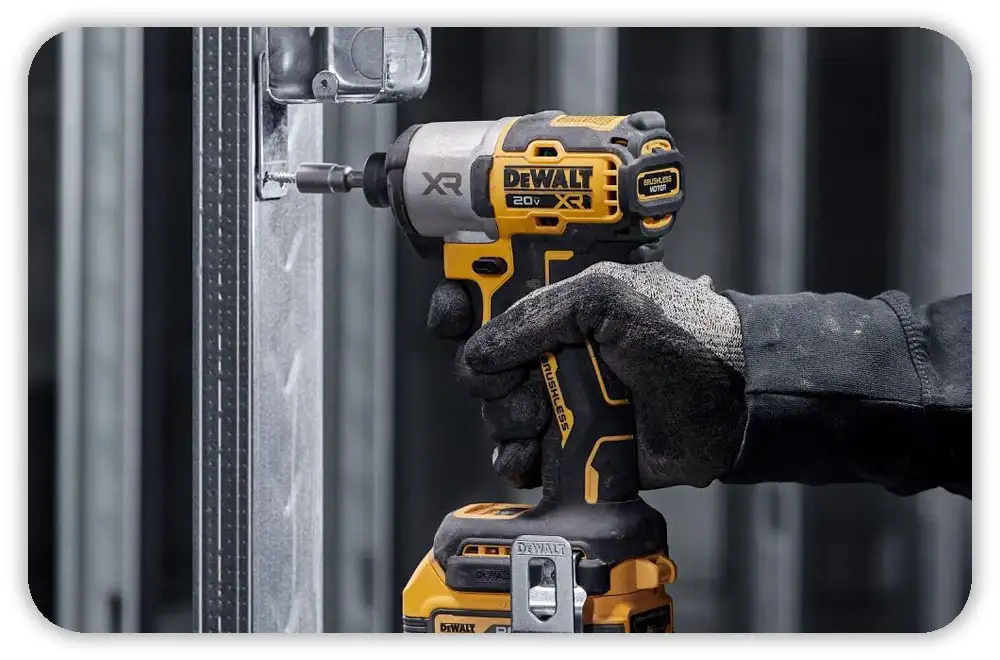

DeWalt

My DeWalt XR gives me more feel and more control. The modes help a lot on soft pine and MDF. I use it when I hang shelves or make small frames. The tool starts slow and climbs smooth.

Makita

Makita feels clean and calm. The motor runs smooth even when the screw fights back. I like it in small shops or tight areas where loud hits feel rough. The trigger is light and easy to guide.

Ryobi

Ryobi helps new owners who want to save money. I used one in a friend’s garage during a shelf job. It drove small and mid-size screws well. It is not as strong as Milwaukee or DeWalt, but it is fine for simple home jobs.

FAQs About Using an Impact Driver

What is the easiest way to use an impact driver?

Start slow. Keep the bit straight. Hold the tool with both hands. Push with light force. Let the impacts sink the screw for you.

Can a beginner use an impact driver safely?

Yes. A new user can run one with easy habits. Wear eye protection. Use a firm grip. Use impact bits only. Start slow and stop when the screw sits flat. Even in cold shops or tight garages, these steps help a lot.

Do you need special bits for an impact driver?

Yes. You need impact bits. Normal bits crack under the hits. Impact bits take the shock and stay firm in the screw. They last longer on decks, fences, and cars.

Why is my impact driver making a loud clicking noise?

The clicks are normal. The hammer hits the anvil inside the tool. This starts when the screw gets tight. It gives more torque to push the screw through.

Can you drill holes with an impact driver?

Yes, but only with impact drill bits. Still, a drill makes cleaner holes. An impact driver is built for screws, not smooth cuts. In soft wood or thin steel, the hits may leave a rough hole.

Final Thoughts: Is an Impact Driver Worth Learning?

I tell new users that an impact driver is worth the time. It saves effort. It works fast even in hard wood or cold metal. I still think of my first fence fix. My drill stalled. The impact driver drove each screw with no strain. It felt like a small win on a long day.